Oxidation ditch effluent weir automatic regulation method and regulation device

A technology of automatic adjustment and water outlet weir, which is applied in the direction of chemical instruments and methods, biological treatment devices, biological water/sewage treatment, etc., can solve the problems of remote and automatic adjustment, lack of adjustment and control methods of oxidation ditch sewage treatment process, fuzzy adjustment Effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

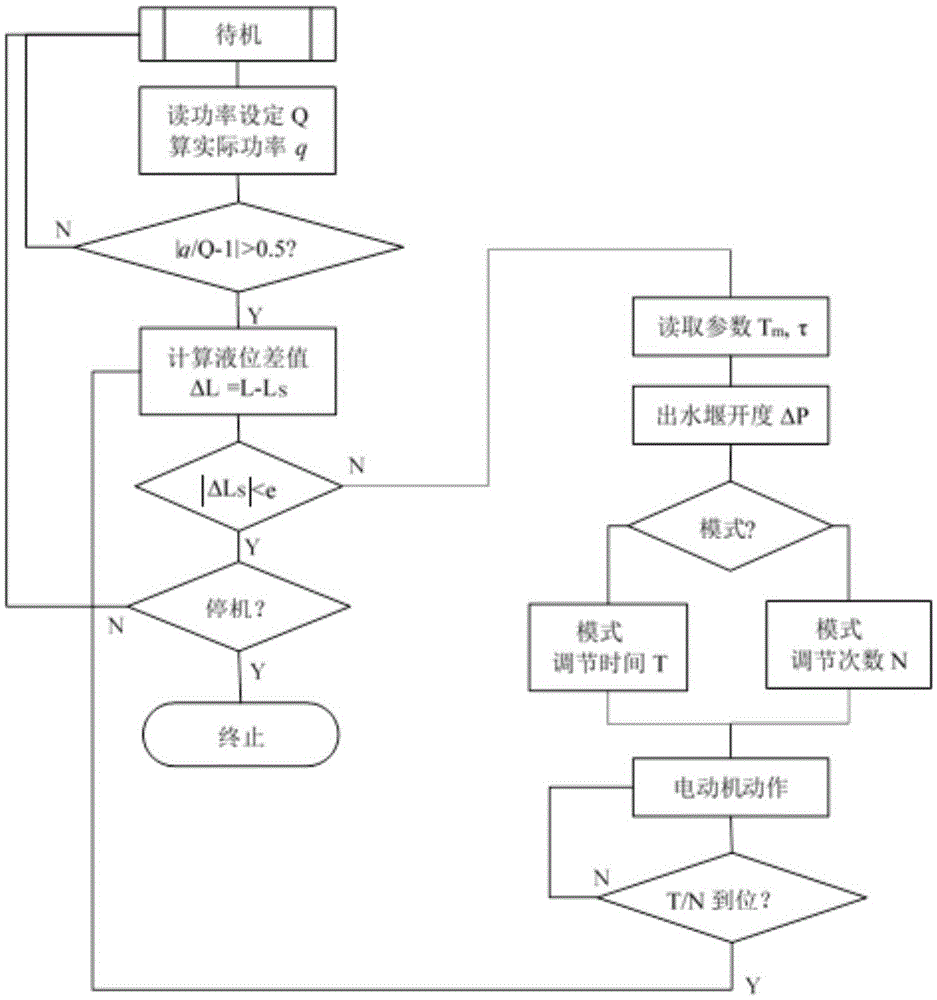

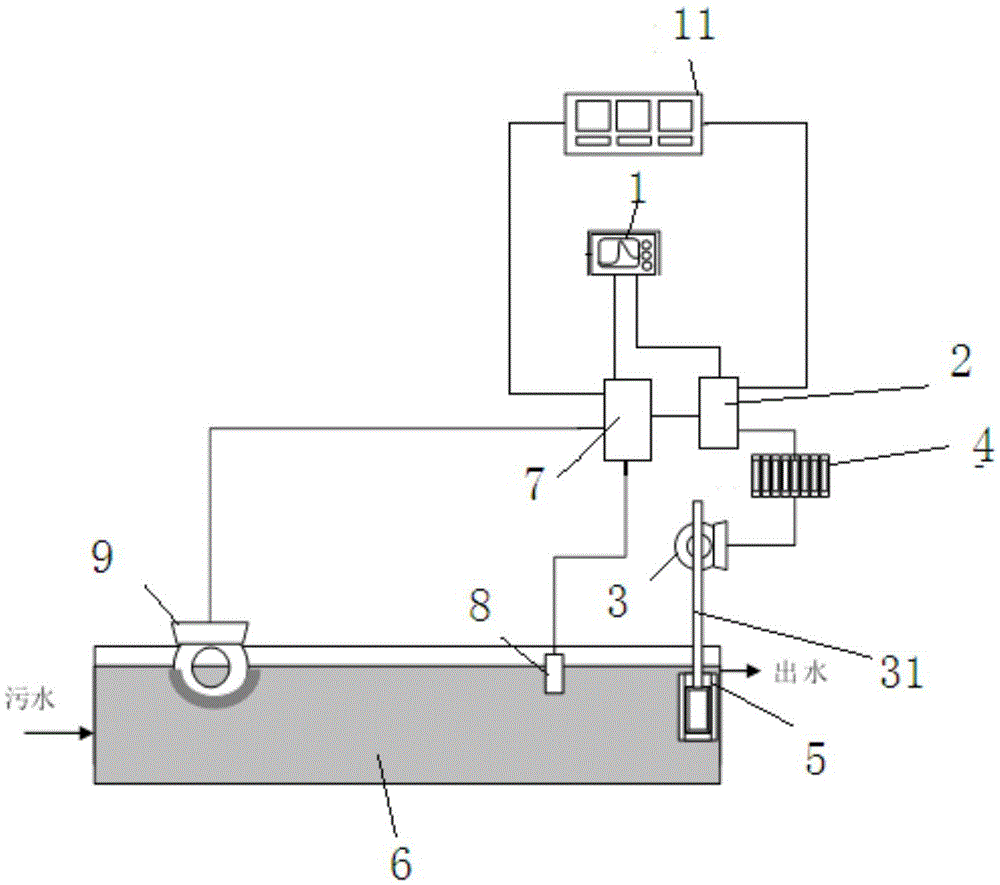

[0047] Such as figure 1 Shown, oxidation ditch outlet weir automatic adjustment method of the present invention comprises the following steps:

[0048] (1) Turn on the controller, process system and electric system respectively, so that the controller, process system and electric system are in standby state respectively;

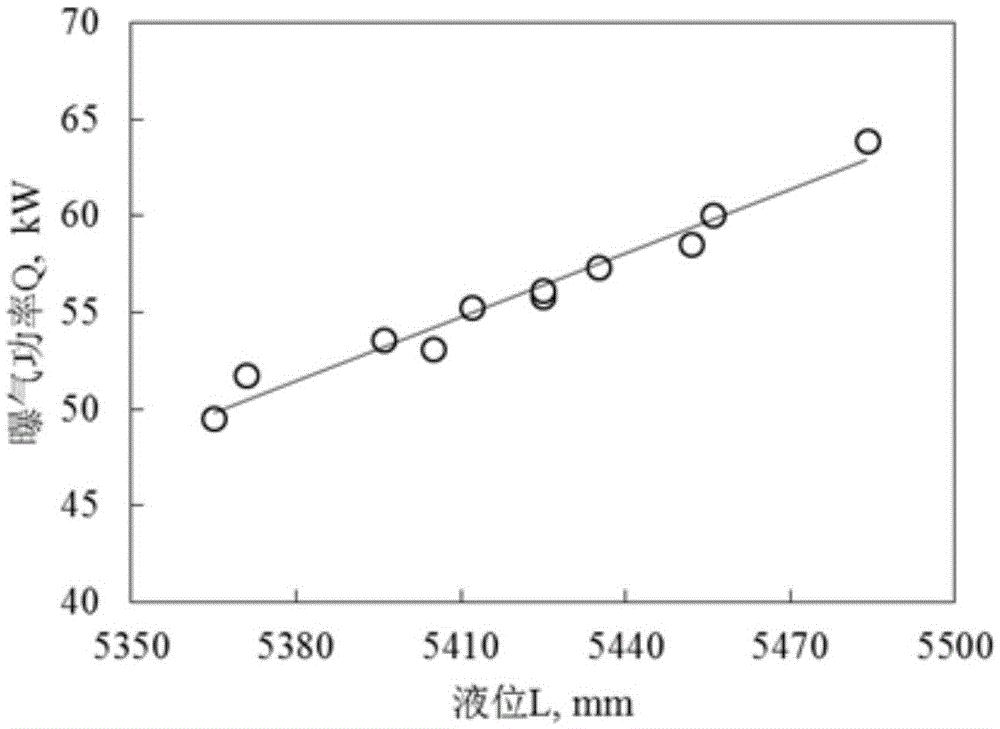

[0049] (2) Input the aeration power setting value Q to the process system through the touch screen of the controller, the process system receives the aeration power setting value Q, and collects the current value of the aeration equipment, and calculates it according to the current value and rated voltage The actual value q of the aeration power, and judge whether the absolute value of q / Q-1 is greater than the preset value of 0.5, if not greater, no adjustment is required, return to step (1), if greater, adjustment is required, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com