A purification system for na+ and cl- ions

An ion and pharmaceutical technology, applied in alkali metal halide purification, electrolysis components, color/spectral property measurement, etc., can solve the problems affecting the production efficiency and product quality of the chlor-alkali exchange membrane process, the low quality of refined brine, and the backward production process, etc. problems, to avoid adverse effects, ensure concentration, and optimize the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

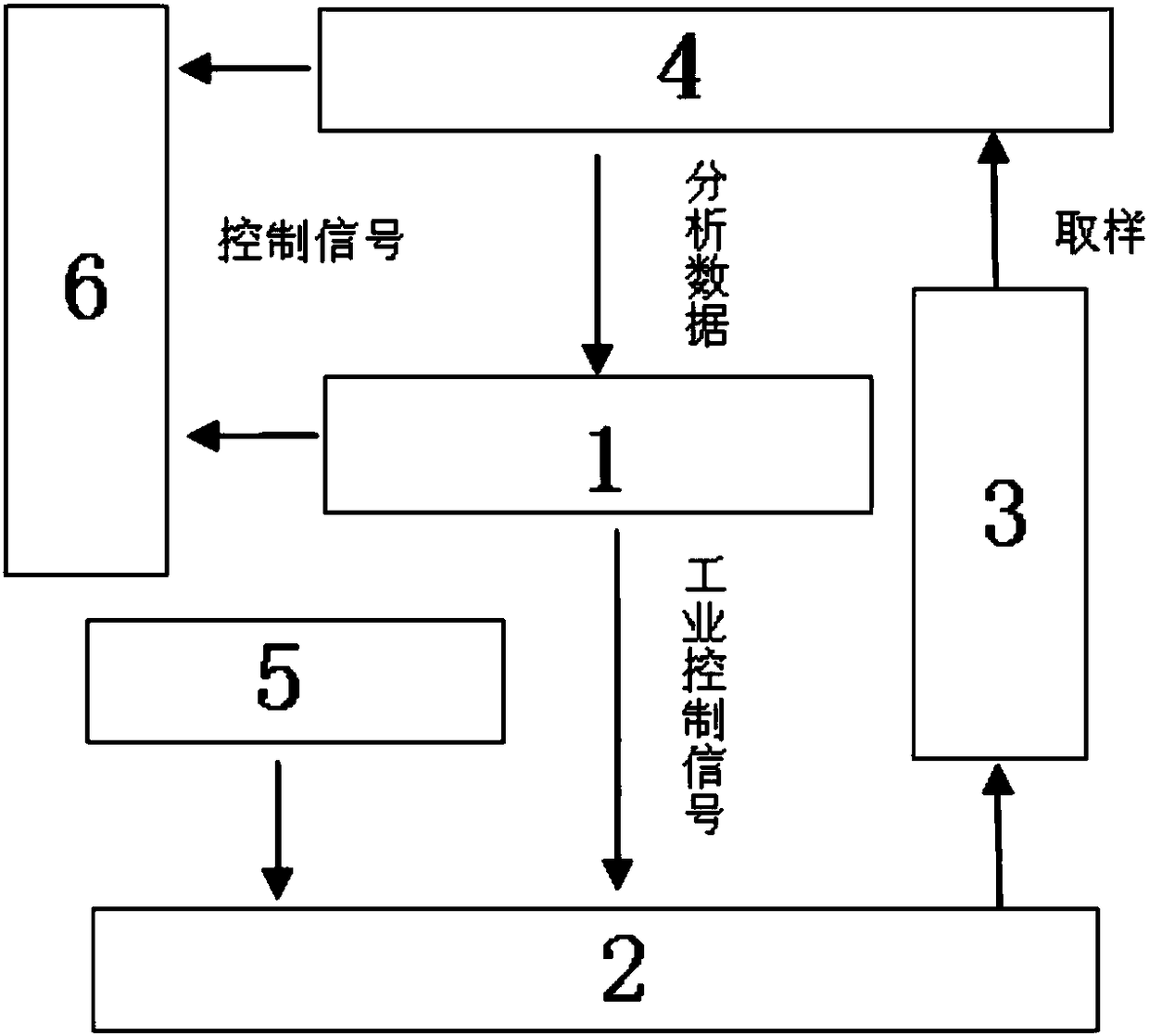

[0019] The present invention integrates the integrated laboratory 4, the Na and CL ion purification agent 5, the purification controller 1, and the volumetric pump 2, so that the control parameters can be calculated while calculating the concentration of each substance in the solution, and the control parameters can be converted The industrial control signal is transmitted to the positive displacement pump, and the ion purification agent is directly injected into the sodium chloride solution that needs to be purified in the chlor-alkali exchange membrane process.

[0020] The purification controller 1 mainly includes an automatic laboratory signal processing circuit, a lower-level executive device control circuit, an alarm output control circuit, and a button switch signal acquisition circuit, wherein the button switch signal acquisition circuit is used to collect manual button trigger switches. The automatic laboratory signal processing circuit is used to collect the signal ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com