Powder material compression molding safety equipment assisted by ultrasonic vibration

A powder material, press molding technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of uneven internal density distribution, inconsistent effective pressure, loss, etc., and achieve high-quality molding Preparation, increase effective pressure, reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

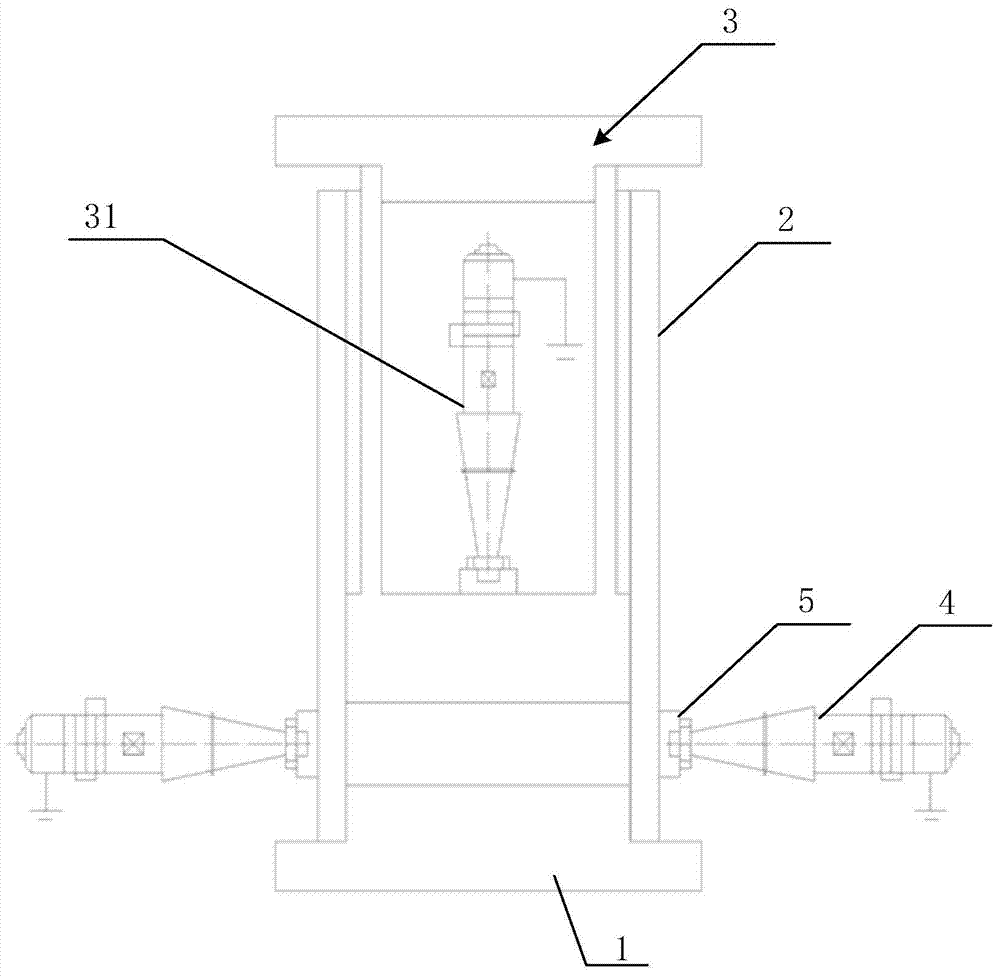

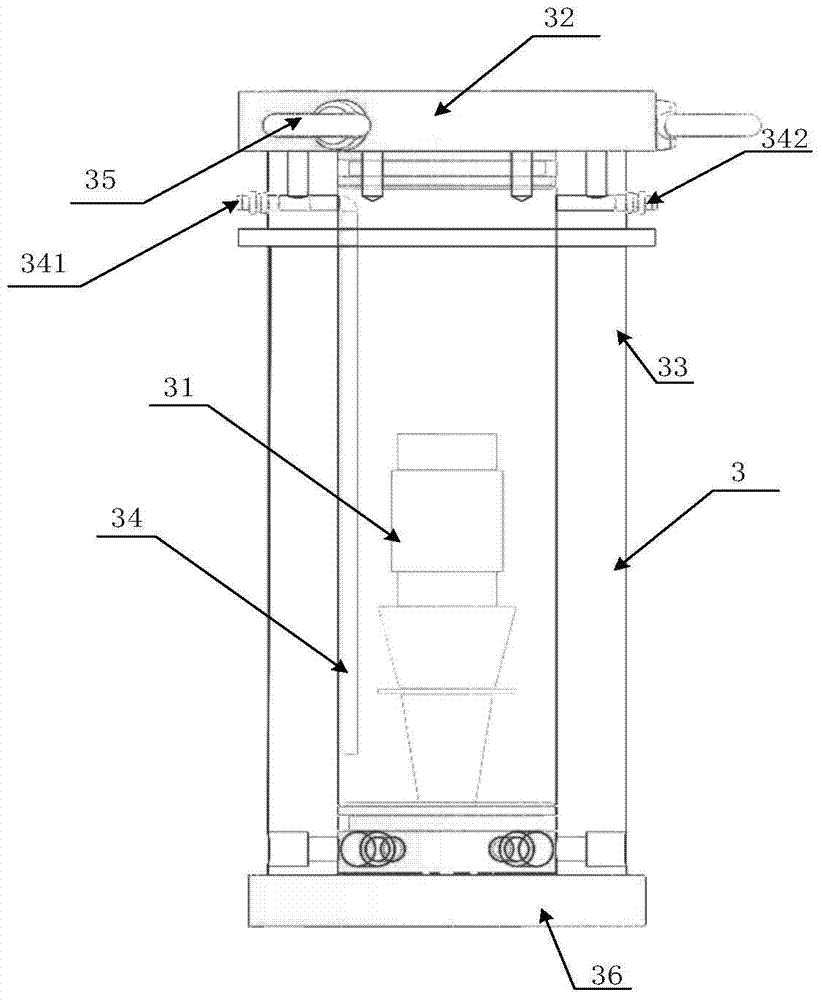

[0029] figure 1 It is a schematic structural diagram of the safety equipment for pressing and molding powder materials assisted by ultrasonic vibration provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the equipment includes an ultrasonic base 1 , an ultrasonic die set 2 installed on the ultrasonic base 1 , an ultrasonic punch 3 used in conjunction with the ultrasonic die set 2 , and a hydraulic press for driving the ultrasonic punch 3 .

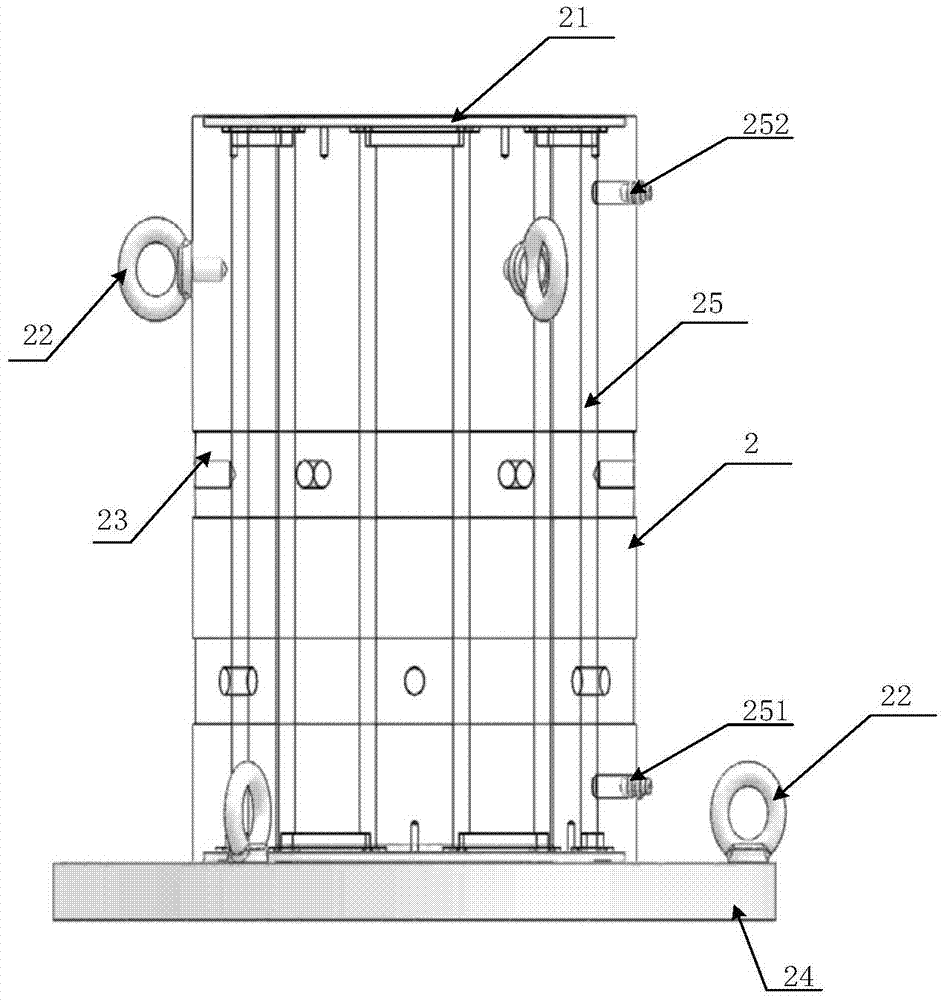

[0030] In this example, if figure 2 As shown, the ultrasonic die set 2 includes a cover plate 21 , eyebolts 22 , a powder pressing chamber 23 , a lower die 24 , and a circulating water cooling system. The circulating water cooling system includes a water pipe 25 , a liquid inlet 251 and a liquid outlet 252 . Eyebolts 22 are provided on the cover plate 21 and the lower die 24 . The joint between the powder pressing chamber 23 and the cover plate 2, the joint between the powder pressing chamber 23 and the liquid...

Embodiment 2

[0039] Embodiment 2 provides a powder material compression molding method assisted by ultrasonic vibration, which includes the following steps.

[0040] Step (1): Place the powder material to be pressed in the ultrasonic mold sleeve, between the ultrasonic punch and the ultrasonic base.

[0041] Step (2): Start the cooling water circulation system, the cooling liquid is injected from the liquid inlet and flows out from the liquid outlet of the cooling water circulation system.

[0042] Step (2) Specifically, inject cooling liquid into the liquid inlet of the ultrasonic mold sleeve and the liquid inlet of the ultrasonic punch, so that the cooling liquid is injected from the liquid inlet of the cooling water circulation system and flows out from the liquid outlet, thereby starting the ultrasonic mold sleeve. The cooling water circulation system and the cooling water circulation system in the ultrasonic punch.

[0043] Step (3): Start the hydraulic press, and the ultrasonic punc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com