Composite sealing cover structure of sulfide-contained mine solid waste landfill field

A solid waste and sulfide technology, applied in the field of environmental geotechnical engineering, can solve the problems of reduced oxygen penetration barrier effect, high later maintenance costs, and difficulty in long-term sustainability, and achieves the effect of eliminating maintenance costs, simple construction and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The average annual precipitation in the area where a certain tailings pond is located is 980mm, the wet season is from June to August, and the dry season is from September to March of the next year. The composite cover of the present invention is laid on the surface of the original tailings 4 in the reservoir area.

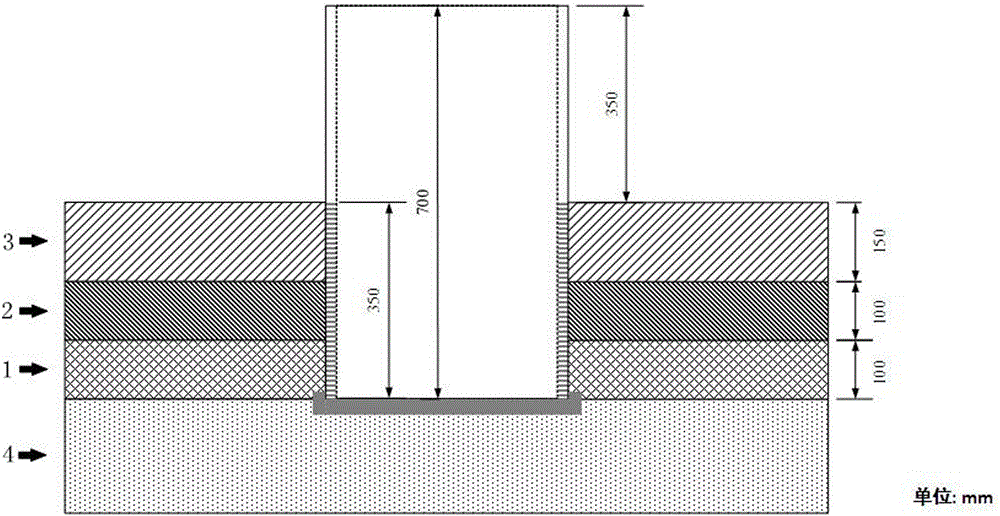

[0034] The composite cover structure of this embodiment is from bottom to top, such as figure 1 As shown, it consists of the first sublayer 1, the second sublayer 2 and the third sublayer 3 in sequence;

[0035] Wherein the first sublayer 1 is directly laid on the surface of the original tailings 4, with a thickness of 10 cm. The material forming the first sublayer 1 is sandy loam, the average particle size is 150 μm, and the matrix suction is 9.18 cm water column. The coefficient is 1.85×10 -5 cm / s;

[0036] The thickness of the second sublayer 2 is 10cm, and the material forming the second sublayer 2 is selected from aeolian sand, the average diameter o...

Embodiment 2

[0042] The purpose of this embodiment is to illustrate the influence of the change of the thickness of the second sublayer in the composite capping structure of the invention on the water evaporation rate of the first sublayer through laboratory tests.

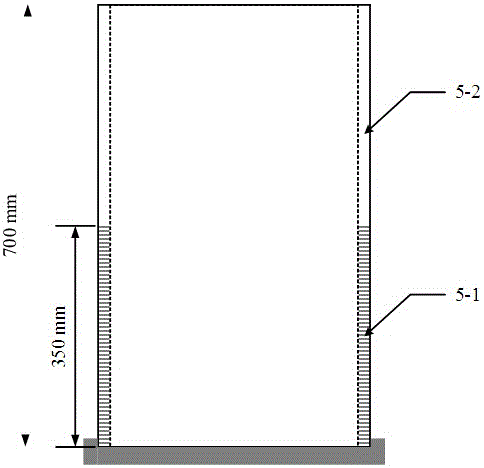

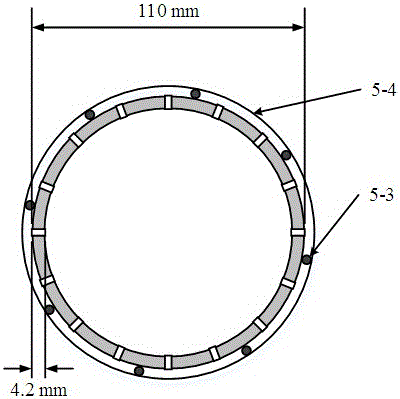

[0043] The equipment used in the indoor test of the present embodiment is as follows: Figure 5 As shown, the test container adopts an acrylic tube 6 with an outer diameter of 110 mm and a wall thickness of 5 mm. Place a 5cm thick permeable stone 9 to prevent the sample in the container from entering the constant water head column 7.

[0044] On the permeable stone 9 in the test container, first lay sulfur-containing tailings with a thickness of 10 cm and a particle size of -6 cm / s, the composite capping layer of this embodiment is laid on the sulfur-containing tailings.

[0045] Among them, the material used in the first sublayer of the composite capping layer is desulfurization gold mine tailings, the average diameter of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com