Automatic electrical heating clay oven roll machine

An electric heating and automatic technology, applied in the field of sesame cake processing, can solve problems such as damage to human health, unbalanced temperature in the pot, pollution of the environment, etc., and achieve the effects of improving quality, protecting scald, and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

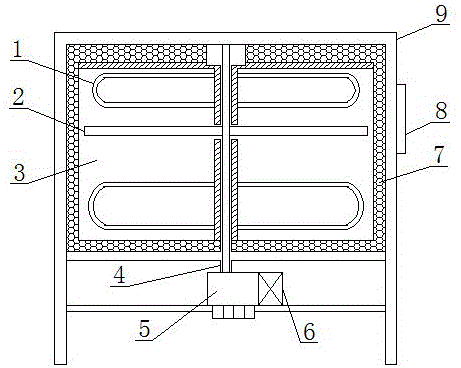

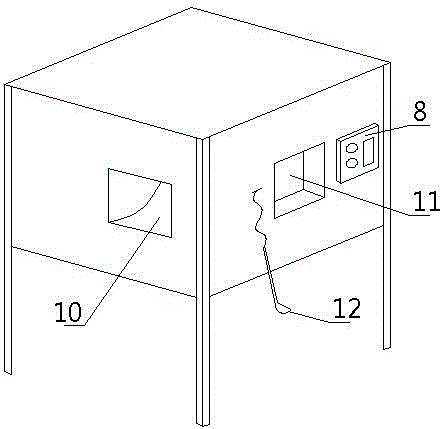

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

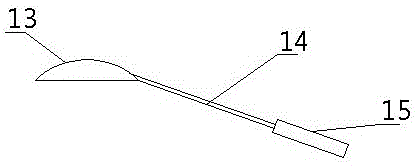

[0018] The electric heating automatic pancake machine of the present invention includes a housing, and is characterized in that: the central position of the inner cavity contained in the housing 9 is provided with a longitudinal rotating shaft 4, and the rotating disc 2 is fixed on the rotating shaft 4; the cavity below the rotating disc 2 A heating tube 1 is arranged inside; a variable speed transmission box 5 is provided at the bottom of the rotating shaft 4, and the variable speed transmission box 5 is driven by a motor 6; a numerical control panel 8 is also provided on the outside of the casing 9, connecting and controlling the heating tube 1 and the variable speed transmission box 5; The housing 9 is also provided with an inlet 11 and an outlet 10 leading into the inner cavity; a spoon-shaped pressure handle is also tied on the outer side of the housing 9 at the inlet 11, and a spoon-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com