Box-packed bean curd and processing technology thereof

A processing technology and tofu technology, which is applied in the field of boxed tofu and its processing technology, can solve the problems of insufficient gel strength, brittleness when fired, sour flavor, etc., and achieve the effects of improving quality, saving manufacturing costs, and ensuring quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

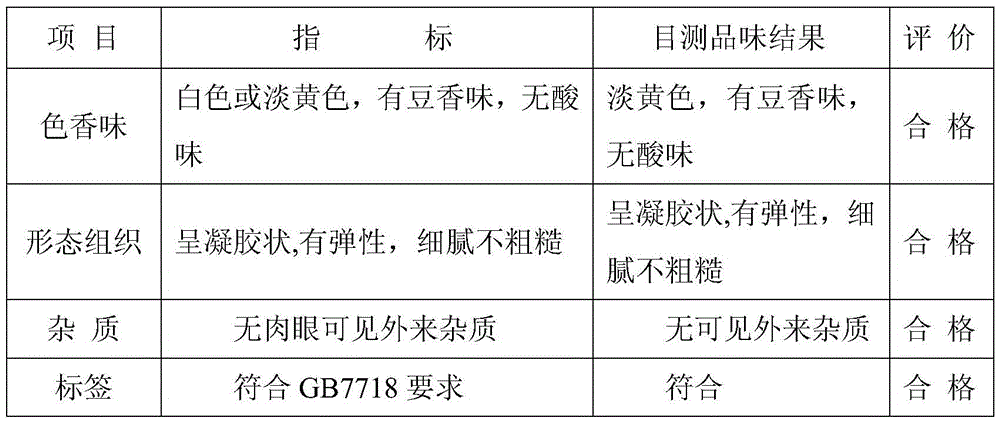

Image

Examples

Embodiment 1

[0027] (1) Material selection: soybeans with large grains, uniformity, plumpness, no mildew, and no impurities are selected as raw materials.

[0028] (2) Soaking: Soak soybeans in water for 8 hours according to the ratio of material to water 1:3.

[0029] (3) Cleaning: Rinse the soaked soybeans with clean water.

[0030] (4) Refining: Refining according to the ratio of soybeans to water 1:4, centrifuging the grated paste for 2 cycles, throwing out the bean dregs to obtain soybean milk, the protein content in the bean dregs is controlled to be less than 3%.

[0031] (5) Burning: Put the soybean milk into the burning tank, control the temperature at 98° C., and keep it for 3 minutes to obtain soybean milk with 11 degrees Baume.

[0032] (6) Sieve: Sieve the burned soybean milk through a 120-mesh sieve.

[0033] (7) Pulping: the temperature of soybean milk is controlled at 80°C, and through automatic pulping equipment, soymilk at 11 degrees Baumé and a composite coagulant aque...

Embodiment 2

[0037] (1) Material selection: soybeans with large grains, uniformity, plumpness, no mildew, and no impurities are selected as raw materials.

[0038] (2) Soaking: Soak soybeans in water for 15 hours according to the ratio of material to water 1:5.

[0039] (3) Cleaning: Rinse the soaked soybeans with clean water.

[0040] (4) Refining: Refining according to the ratio of soybeans to water 1:5, centrifuging the grated paste for 3 cycles, throwing out the bean dregs to obtain soybean milk, the protein content in the bean dregs is controlled to be less than 3%.

[0041] (5) Burning: Put the soybean milk into the burning tank, control the temperature at 100° C., and keep it for 5 minutes to obtain soybean milk with 14 degrees Baume.

[0042] (6) Sieve pulp: pass the soya-bean milk that burns through 220 mesh sieves and sieve pulp.

[0043] (7) Washing: the temperature of the soybean milk is controlled at 90°C, and through the automatic washing equipment, the soybean milk of 14 d...

Embodiment 3

[0047] (1) Material selection: soybeans with large grains, uniformity, plumpness, no mildew, and no impurities are selected as raw materials.

[0048] (2) Soaking: Soak soybeans in water for 10 hours according to the ratio of material to water 1:4.

[0049] (3) Cleaning: Rinse the soaked soybeans with clean water.

[0050] (4) Refining: Refining is carried out according to the ratio of soybeans to water 1:4.5, and the paste is centrifuged through 2.5 cycles, and the bean dregs are thrown out to obtain soybean milk. The protein content in the bean dregs is controlled to be less than 3%.

[0051] (5) Burning: Put the soybean milk into the burning tank, control the temperature at 99° C., and keep it for 4 minutes to obtain soybean milk with 12 degrees Baume.

[0052](6) Sieve: Sieve the burned soybean milk through a 180-mesh sieve.

[0053] (7) Washing: the temperature of soybean milk is controlled at 85°C, and through the automatic washing equipment, the soybean milk of 12 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com