Continuous wire clip for overhead insulation circuit

An overhead insulation and splicing wire technology, applied in the direction of needle point/slotted plate contacts, circuits, connections, etc. used to penetrate insulated wires/cable core wires, can solve problems such as poor firmness and easy loosening, and reduce vibration , The distribution of the center of gravity is reasonable, and the effect of ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

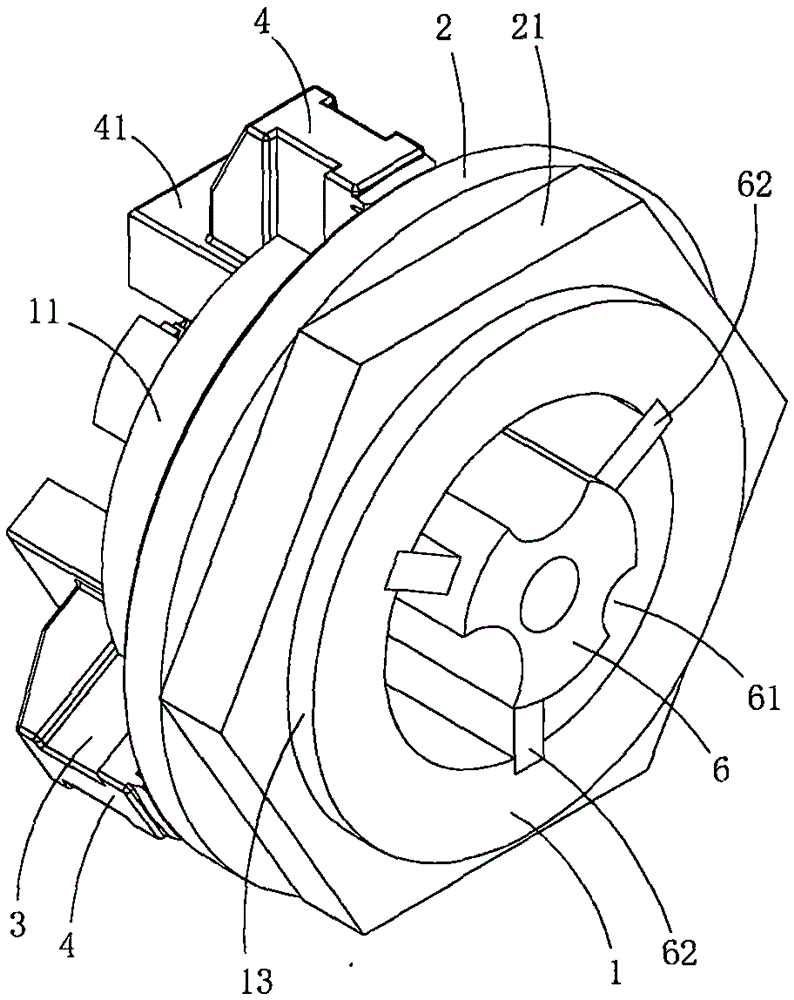

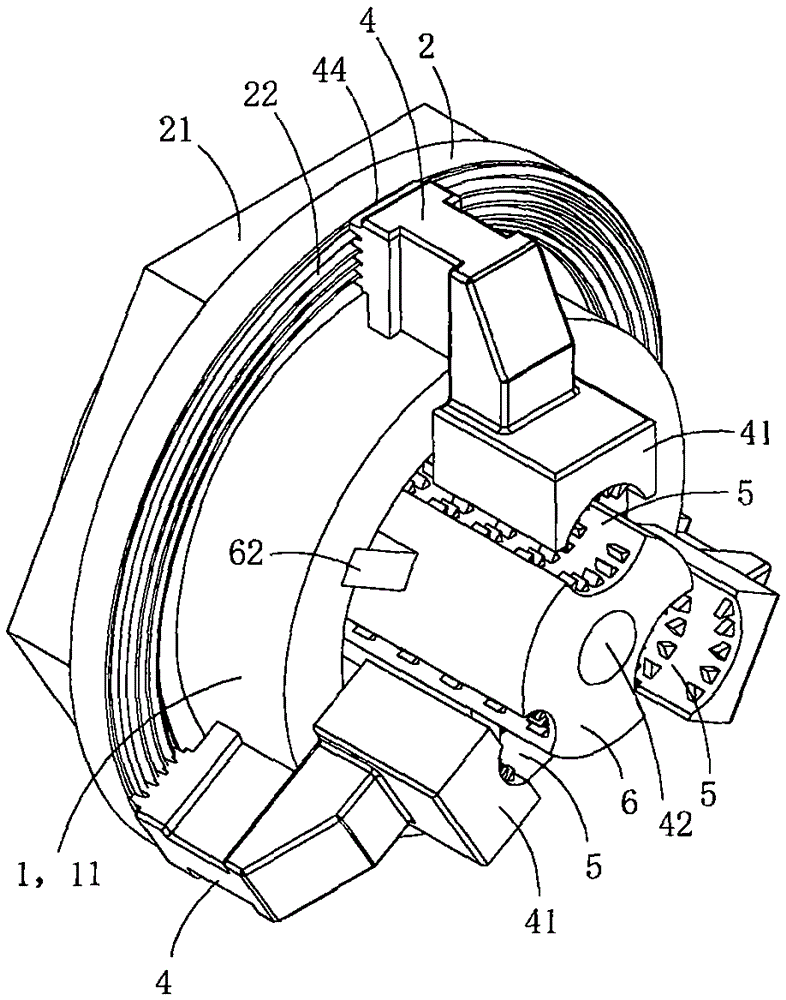

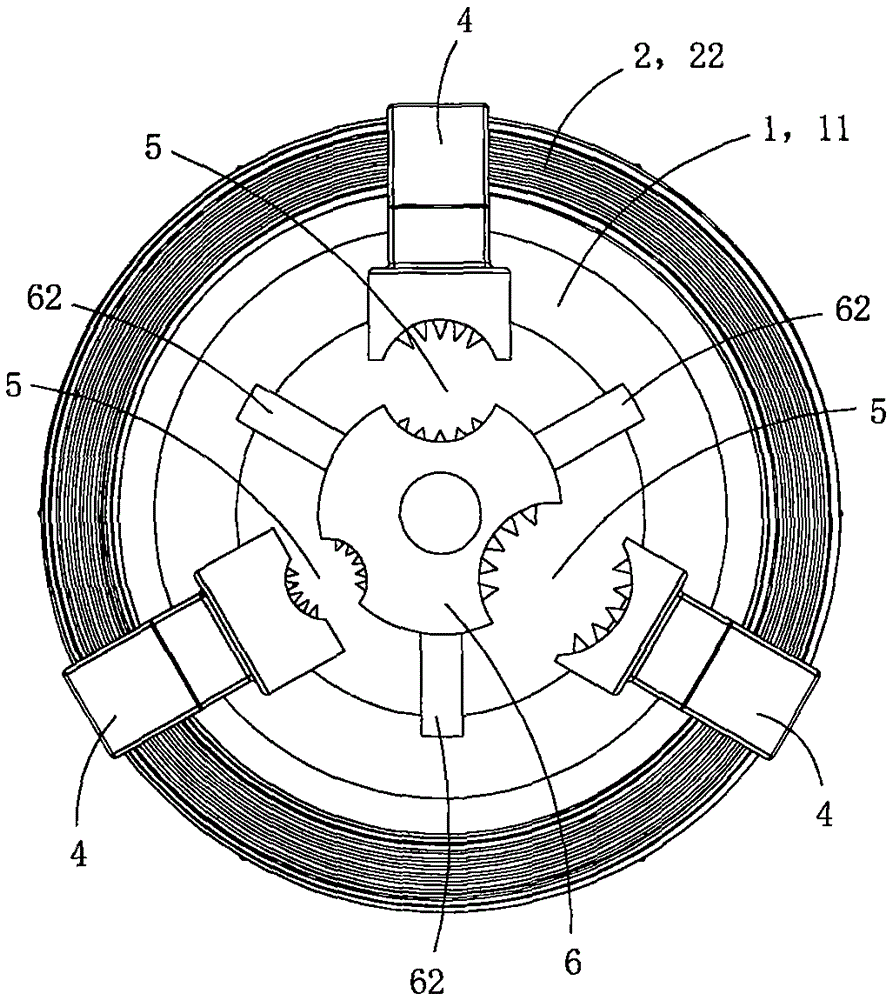

[0017] The present embodiment is a kind of splicing clip for overhead insulated lines, see Figure 1 to Figure 7 As shown, it includes a base body 1, a flat nut 2 and a set of pressure jaw assembly 3, the pressure jaw assembly includes three pressure jaws 4; the base body is provided with a slide tube 11, a radial guide limit hole 12 arranged on the slide tube and The block 13 that is arranged on the outer peripheral wall of the slide tube protrudes outward along the radial direction of the slide tube; the radial guide limit hole penetrates the tube wall of the slide tube along the radial direction of the base slide tube; the shape of the block is ring-shaped, and the block It is located at one end of the base sliding tube in the axial direction, and the radial guide limiting hole 12 is located at the other end of the base sliding tube in the axial direction;

[0018] The quantity of radial guide limit hole 12 is the same as the quantity of pressure jaw 4, also is three; Slid...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 8 As shown, the length of the base slide tube in this embodiment is slightly longer, and a voltage transformer 7 is sheathed and fixed on the outer peripheral wall of the base slide tube. Since the power cable passes through the lumen of the base slide tube, the voltage transformer The device can obtain a lower induced voltage through induction, which can be used as a power supply for auxiliary equipment. For example, a camera with a wireless transceiver unit, a temperature sensor, a humidity sensor or a lightning strike counter and other auxiliary equipment can be fixedly installed on the lower part of the base slide tube to monitor the environment around the clamp in real time, and the real-time The information is sent to the remote host to provide basic data for the intelligentization of power lines; and the voltage transformer in this embodiment provides stable and sustainable powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com