Combined locknut

An anti-loosening nut and combined technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of inconvenient operation, cannot be reused, no anti-loosening function, etc., and achieve simple operation, lasting anti-loosening effect, and good anti-loosening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

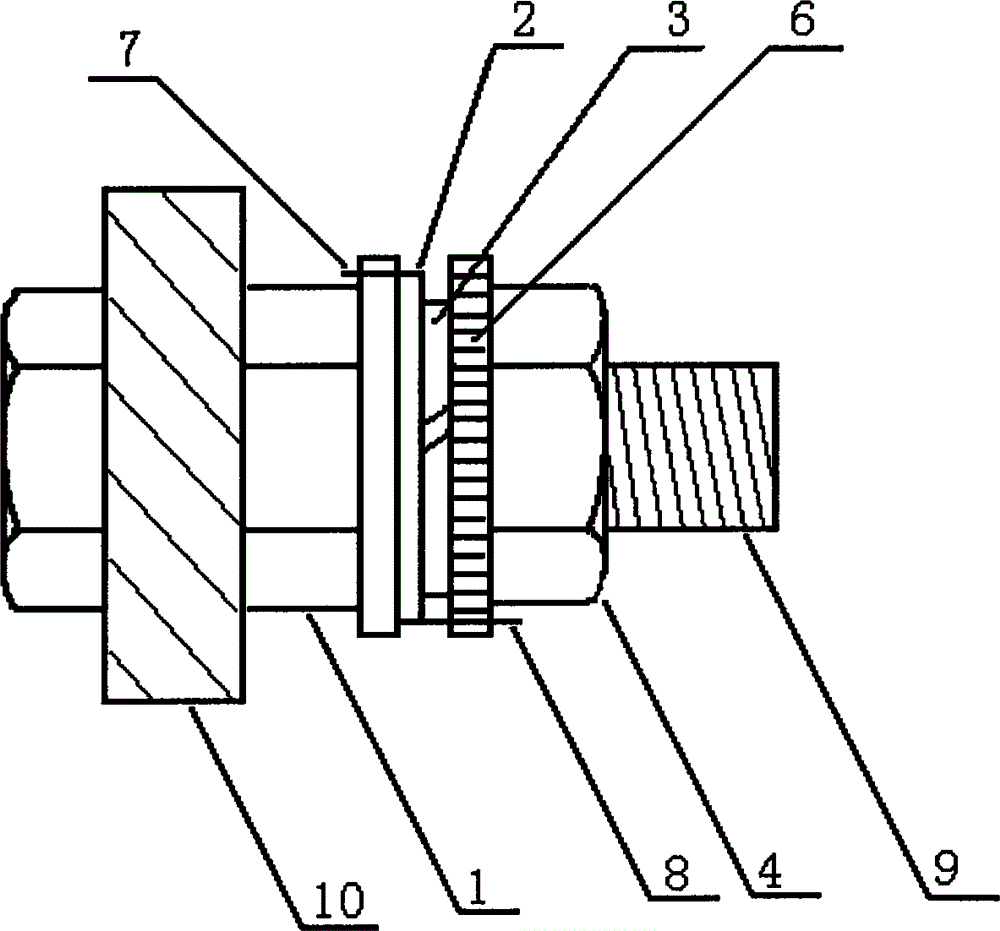

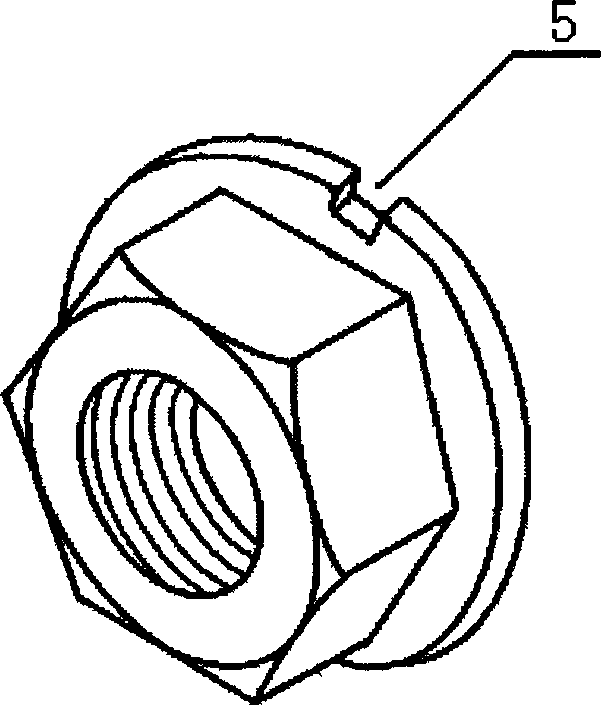

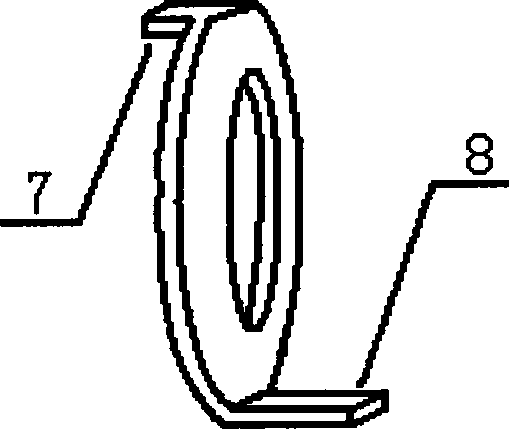

[0016] A combined anti-loosening nut includes a fastening nut 1, a stop washer 2, a spring washer 3 and a compression nut 4. The lower end surface of the fastening nut 1 has a flange portion, and the outer circular side of the flange portion is provided with a limit groove 5 corresponding to the stop ear 7 of the stop washer 2 . The two radial square protrusions on the outer circle of the stop washer 2 are folded sideways by 90 degrees in opposite directions in the axial direction to form stop ears 7 and stop ears 8 . The upper end surface of the compression nut 4 has a flange portion, and the outer circular side of the flange portion is engraved with uniform and continuous zigzag anti-skid teeth 6 , and the direction of the anti-skid teeth 6 is opposite to the tightening direction of the compression nut 4 . The outer diameter of the spring washer 3 is smaller than the outer diameter of the stop washer 2, so that the stop ear 8 of the stop washer 2 can cross the outer diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com