In situ test instrument and method for mechanical, electric, thermal and magnetic coupling material properties under composite load mode

A technology of composite load and material properties, which is applied in the application of repetitive force/pulsation force to test the strength of materials, instruments, and the use of stable tension/pressure to test the strength of materials, etc. It can solve the problem of in-situ testing of material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

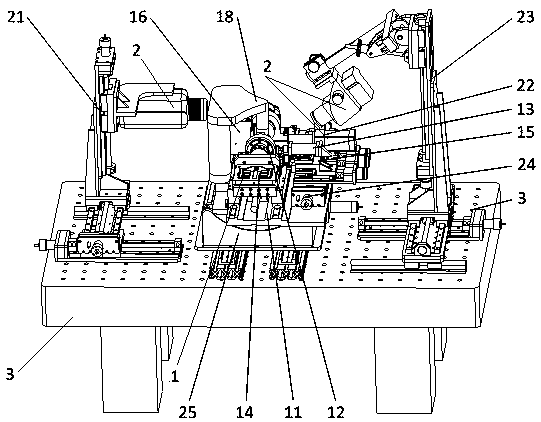

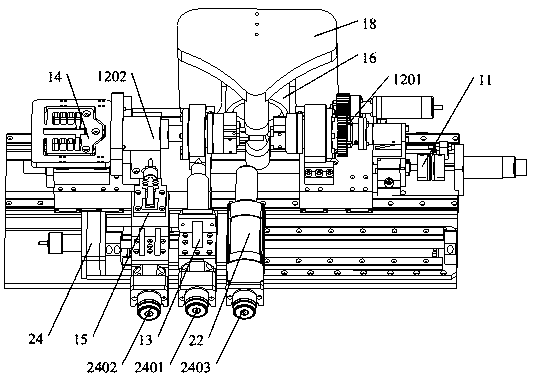

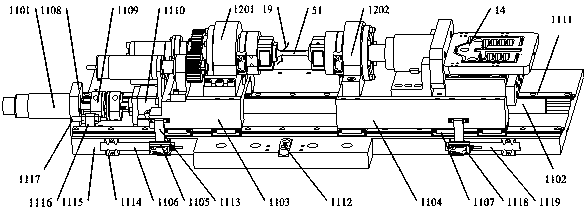

[0047] see Figure 1 to Figure 19 As shown, the in-situ test instrument for the composite load mode electrothermal-magnetic coupling material performance of the present invention includes a composite load-multiphysics field loading test platform 1, an in-situ monitoring platform 2 and a vibration isolation base 3, and the vibration isolation base 3 is used to support composite load-multi-physics field loading test platform 1 and in-situ monitoring platform 2, providing basic installation and positioning for them, and providing effective vibration isolation treatment for the testing process; vibration isolation base 3 provides testing equipment The support of the whole machine and a stable and vibration-free experimental environment, if it is necessary to create a vacuum environment, the core parts such as the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com