A method for detecting agglomeration in a stirred bed reactor

A reactor and stirred bed technology, which is applied in the detection field of agglomeration in a stirred bed reactor, can solve the problems of inability to judge and deal with agglomeration in time, lack of detection means for agglomeration, and affect normal reaction, etc., and achieves easy installation and use Broad, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

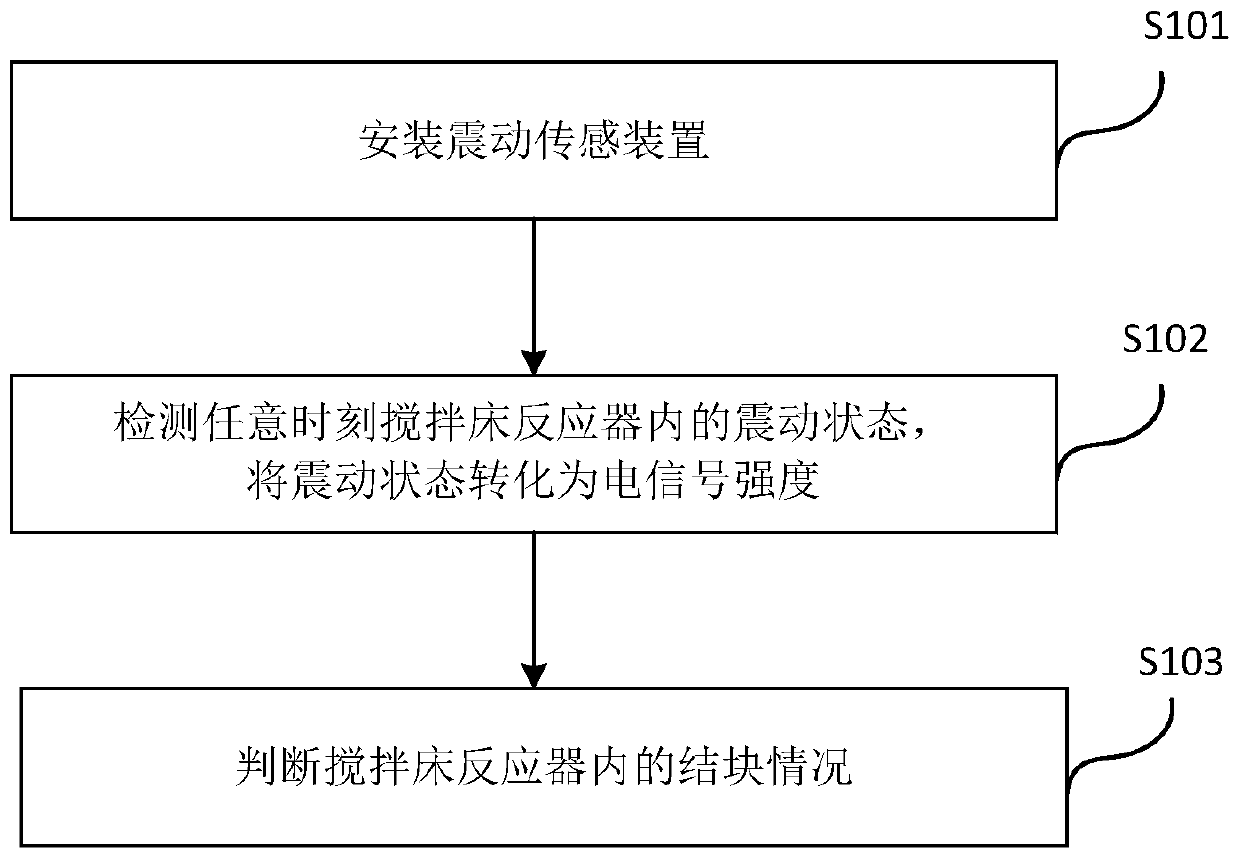

[0025] The invention provides a kind of detection method of agglomeration in the stirred bed reactor, it comprises the following steps:

[0026] Installation step S101, setting at least one vibration sensing device on the side wall of the stirred bed reactor;

[0027] Detection step S102, detecting the vibration state in the stirred bed reactor at any time through the vibration sensing device, and converting the vibration state into an electrical signal intensity;

[0028] Judging step S103, judging the caking situation in the stirred bed reactor according to the corresponding relationship between the electrical signal intensity output by the vibration sensing device and the caking mass in the stirred bed reactor.

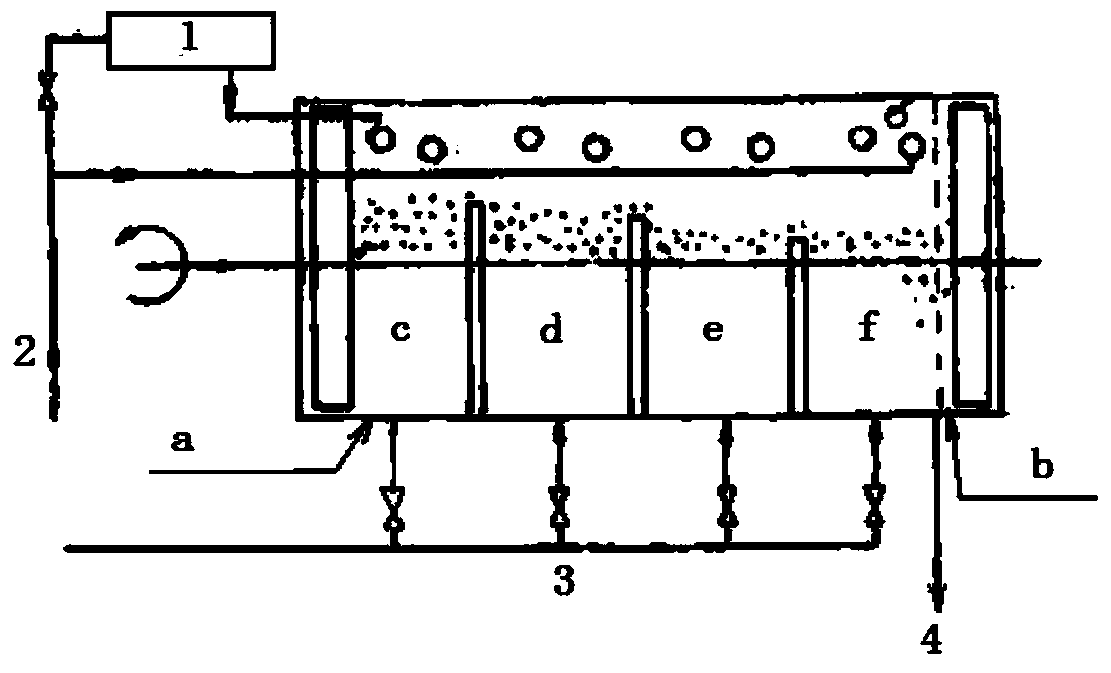

[0029] The schematic flow chart of the present invention is as figure 1 shown. The method of this embodiment first executes step S101, installing the vibration sensing device on the side wall of the stirred bed reactor. The vibration sensing device is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com