Solidified flatness sampling device for construction engineering

A construction engineering and sampling device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of high manufacturing cost and complex structure, and achieve the effect of convenient sampling and accurate sampling results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

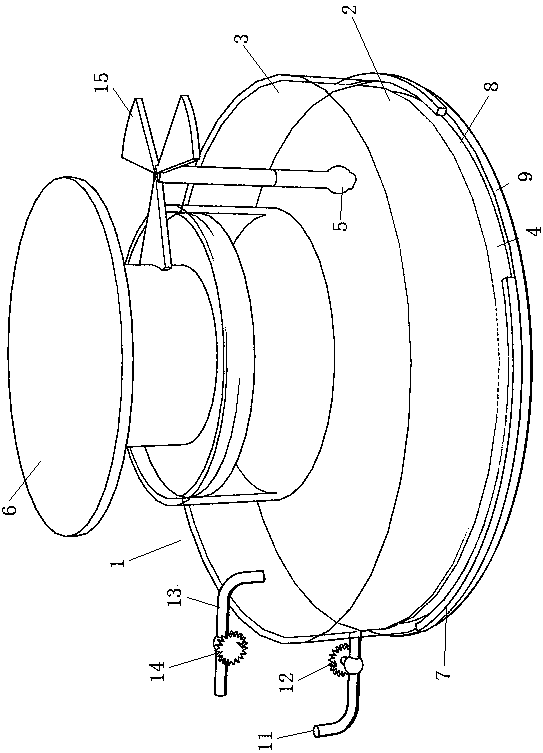

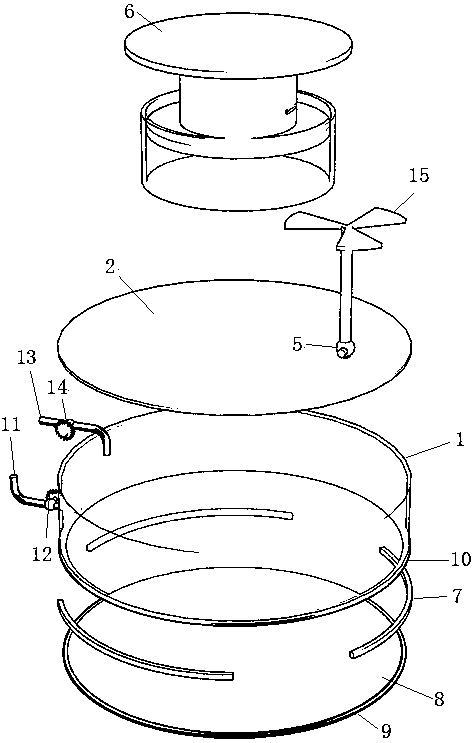

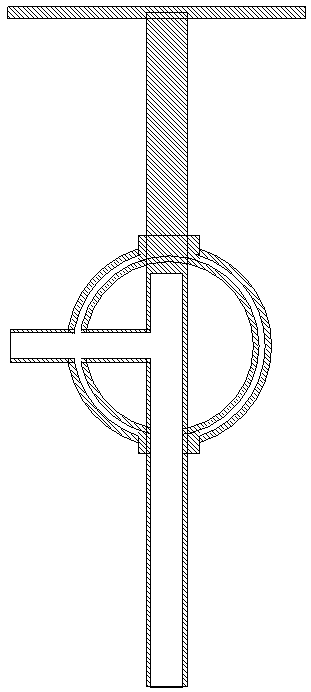

[0015] Such as Figure 1-3 As shown, the solidified flatness sampling device for construction engineering includes a dark box 1; a horizontally arranged light-shielding hard baffle 2 is installed in the middle of the inner cavity of the dark box 1; the light-shielding hard baffle 2 divides the dark box 1 into liquid storage located above The tank 3 and the curing tank 4 located below; the liquid storage tank 3 and the curing tank 4 are connected through a pipeline provided with a switch ball valve 5; A UV lamp 7 is evenly installed on the side wall of the curing box 4, and the lower end of the curing box 4 is sealed with a sampling rubber film 8; the liquid storage tank 3 is filled with liquid photosensitive resin; the inside of the curing box 4 is in a vacuum state. The outer side of the sampling rubber film 8 is fixed with a hard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com