Fast green brick baking device

A baking device and adobe technology, which is applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of limiting the baking efficiency of adobe, making it difficult to bake adobe, and the efficiency of adobe baking cannot be effectively improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

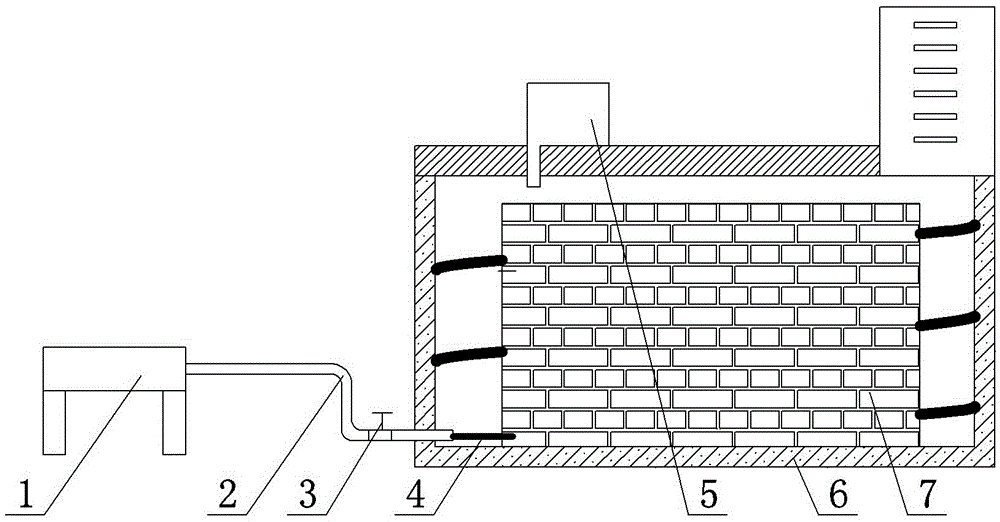

[0014] The reference signs in the drawings of the description include: furnace body 1, baking pipe 2, check valve 3, air outlet pipe 4, air blower 5, furnace kiln 6, brick adobe 7.

[0015] The embodiment is basically as figure 1 Shown: a quick-brick baking device, including a furnace body 1, which is provided with a furnace door and a furnace bridge, and also includes a kiln 6 for baking bricks 7 . A baking pipe 2 is arranged between the furnace body 1 and the furnace kiln 6 , and the left end of the baking pipe 2 communicates with the fire outlet of the furnace body 1 . The furnace kiln 6 is provided with an air intake installation port for the passage of the baking pipe 2 , and the right end nozzle of the baking pipe 2 passes through the air intake installation port to reach the furnace kiln 6 . Such as figure 1 As shown, the inside of the kiln 6 is provided with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com