Automatic blowout device after oil and water well fracturing

A post-fracturing, oil-water well technology, applied in wellbore/well valve devices, wellbore/well components, and production fluids, etc., can solve the problem of easy stab damage, heavy workload, and poor gate closure safety accidents, etc. problems, to achieve the effect of avoiding workload, easy installation, and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

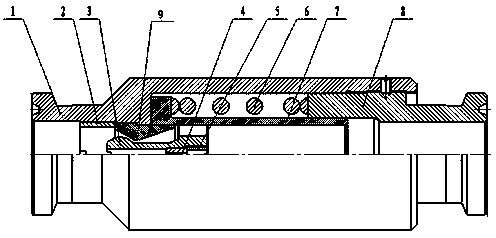

[0014] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0015] Such as figure 1 As shown, the automatic blowout device after oil-water well fracturing includes a valve body 1, a lower joint 8, and an automatic adjustment device. The valve body is connected to the lower joint. Return elastic movement mechanism, a valve core is set in the center cavity of the valve body, the outer side of the lower half of the valve core is connected to the automatic return elastic movement mechanism, the outer side of the upper half of the valve core 3 is spherical, corresponding to the upper end of the valve core The inner wall of the outer valve body 1 is fixed with a valve mouth 9, the inner side of the valve mouth is trumpet-shaped, a nozzle is formed between the outer wall of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com