Simple automatic spraying device

An automatic spraying and simple technology, applied in the direction of spraying devices, etc., can solve the problems of damage to spraying operators, high cost of spraying by manipulators, poisoning, etc., and achieve the effect of avoiding damage, realizing low-cost automation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

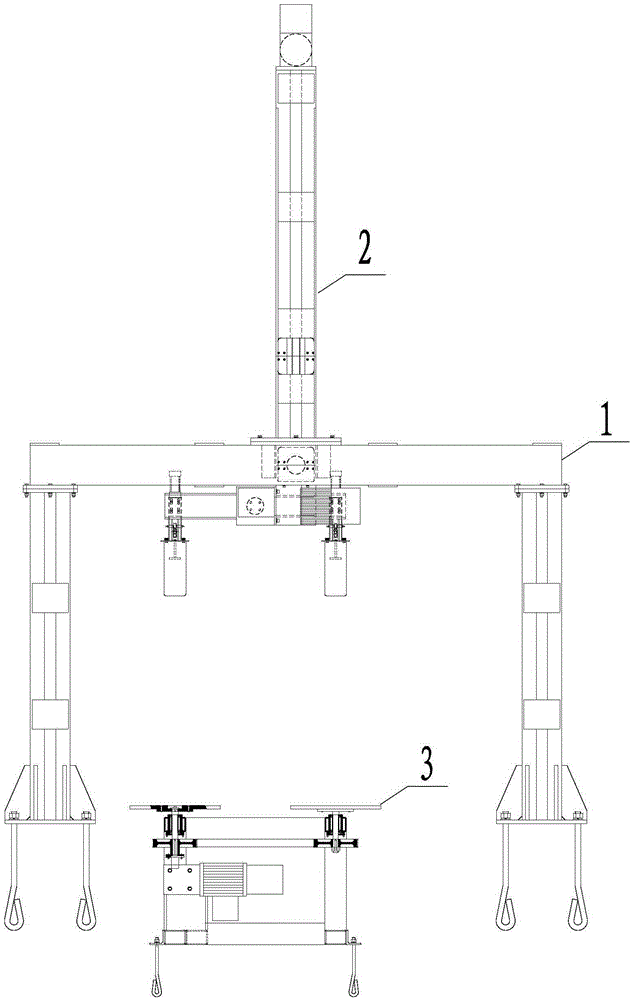

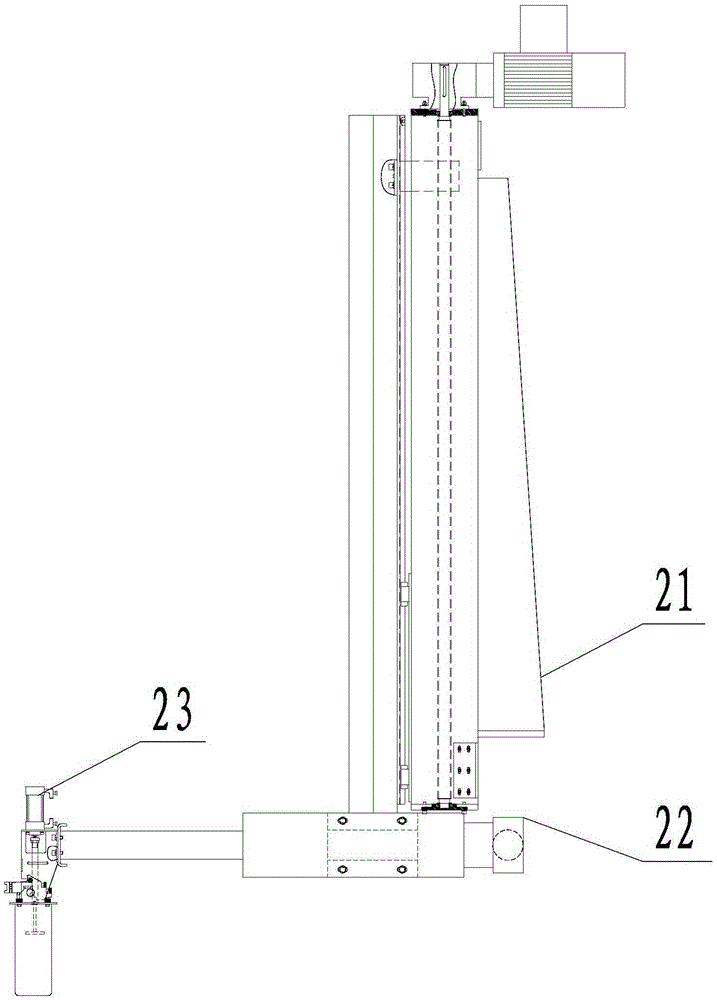

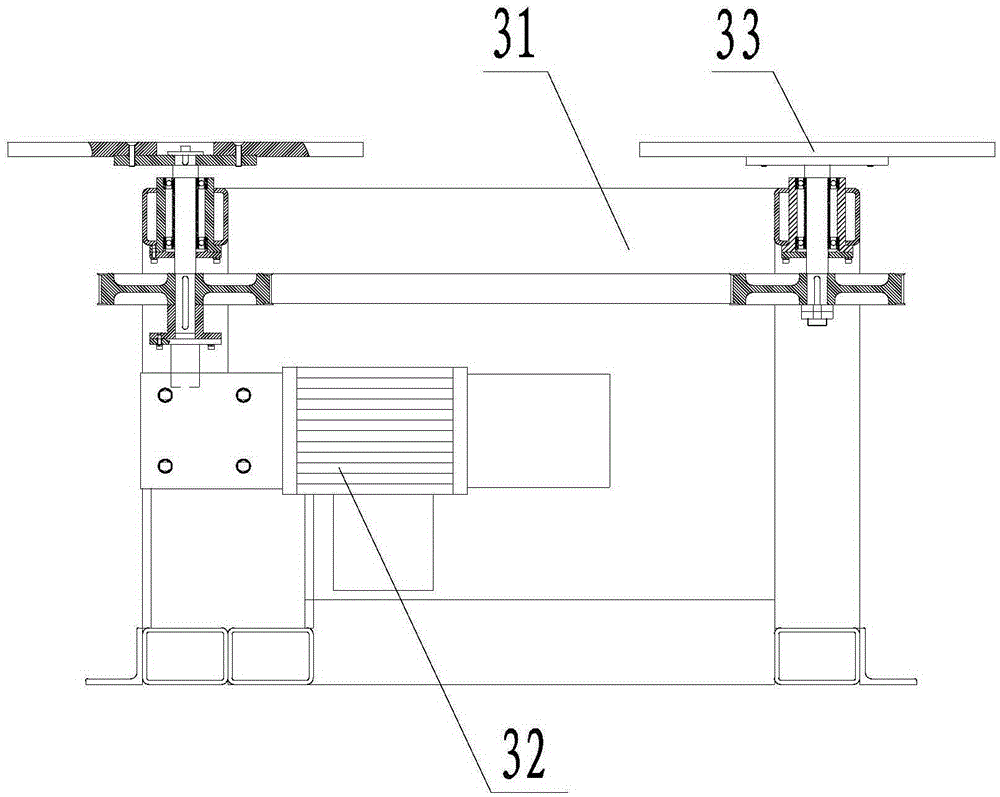

[0014] like Figure 1 to Figure 3 A simple automatic spraying device shown includes a gantry 1, a spraying mechanism 2, and a clamping mechanism 3; the gantry 1 is a "door"-shaped welded frame; the spraying mechanism 2 consists of a lifting assembly 21, a radial The moving assembly 22 and the spraying assembly 23 are composed of the lifting assembly 21 vertically passing through the top cross frame of the gantry 1, the bottom of the lifting assembly 21 is horizontally fixed to the radial moving assembly 22, and the end of the radial moving assembly 22 is vertically fixed to the spraying assembly 23; The clamping mechanism 3 is composed of a frame 31 and a workbench 33, and the workbench 33 is fixed on the tops of both sides of the frame 31; the spraying assembly 23 is directly above the workbench 33.

[0015] The spraying assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com