A fully automatic spraying mechanism for building walls that can adjust the spraying angle in real time

A technology of spraying angle and real-time adjustment, applied in building structures, buildings, etc., can solve problems such as poor spraying effect, high labor intensity, and difficulty in spraying inclined walls, and achieve high work efficiency, good spraying effect, and scope of application. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

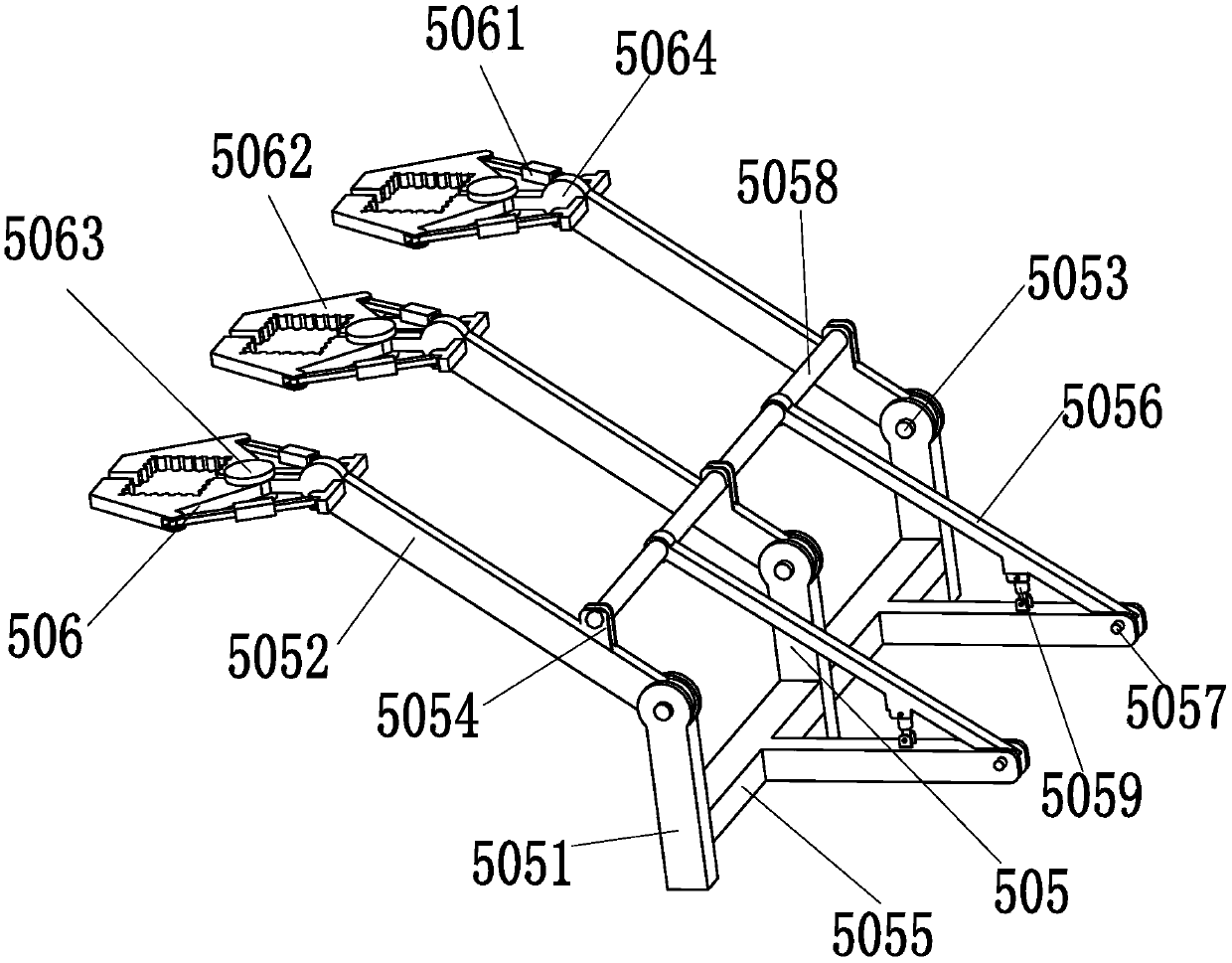

[0013] Such as figure 1 and figure 2 As shown, a fully automatic spraying mechanism for building walls that can adjust the spraying angle in real time, including a spraying platform 501, a spraying slide rail 502, a spraying slider 503, a connecting horizontal plate 504, a spraying boom 505, a spraying jaw 506 and a translation Push rod 507, the spraying platform 501 is a cuboid structure, the spraying platform 501 is installed on the existing mobile equipment, the number of spraying slide rails 502 is five, the spraying slide rails 502 are installed on the upper end surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com