Construction method of large-cross-section, porous, super-long and cast-in-place box culvert

A construction method and large-section technology, which can be used in construction, road bottom and other directions, can solve the problems of concrete construction impact, limited control range, reduced construction efficiency, etc., to improve construction flexibility and structure compactness, improve construction quality, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

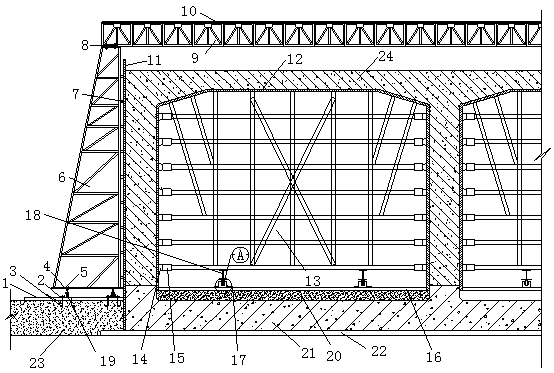

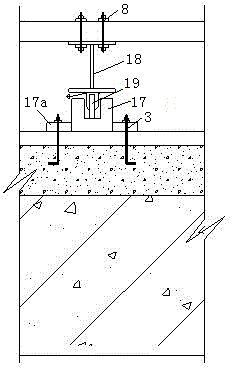

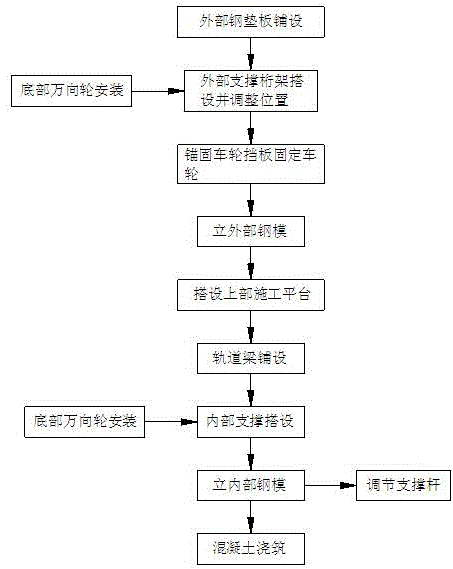

[0038] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

[0039] Such as Figure 1-3 As shown, the construction method of the large-section porous super-long cast-in-place box culvert of the present invention mainly comprises the following construction steps:

[0040] 1) Concrete and filling construction: pour foundation cushion 22, box culvert bottom structure layer 21 and box culvert bottom surface layer 20 at the design position in sequence according to the setting requirements, and fill soil on the periphery at the same time to obtain the external filling layer 23;

[0041]2) Laying of external steel backing plate 1: Before hoisting, set embedded holes at the designated position for laying external steel backing plate 1, hoist the external steel backing plate 1 to the vicinity of the design position, and place temporary block;

[0042] 3) Er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com