Cast aluminum alloy micro-arc oxidation ceramic membrane layer and preparation method thereof

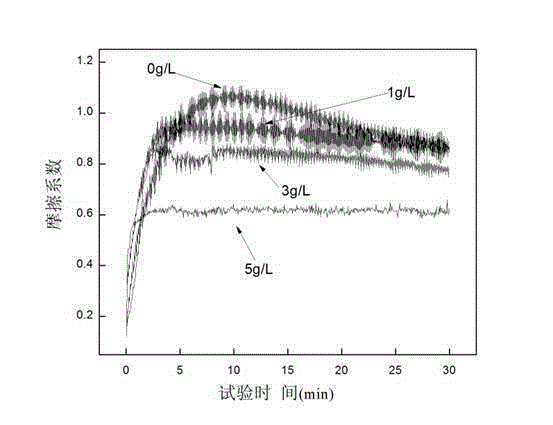

A technology of casting aluminum alloy and micro-arc oxidation, which is applied in anodic oxidation and other directions, can solve the problems of rough surface, poor surface quality of ceramic film layer, and reduce the wear resistance of surface ceramic layer, so as to achieve small roughness, smooth surface, and improved The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw material preparation: 15g / L Na 2 SiO 3 ?9H 2 O, 3g / L Na 2 MnO 4 ?2H 2 O, 3g / L NaF, 8g / L NaOH, 1g / L Bi 2 o 3 , the solvent is deionized water, the sample is ZL101A cast aluminum alloy of 50mm×20mm×3mm, polished smooth by #800, #1000, #1500 sandpaper step by step, cleaned with deionized water and dried.

[0027] Material preparation: According to the above composition, Na 2 SiO 3 ?9H 2 O, Na 2 MnO 4 ?2H 2 O, NaF, NaOH and Bi 2 o 3 Add deionized water to make a bath, ultrasonically vibrate the bath for 10 minutes, then magnetically stir for 20 minutes, then add to the micro-arc oxidation electrolytic cell, and stir it.

[0028] A 20kW DC pulse micro-arc oxidation device is used to perform micro-arc oxidation on the surface of cast aluminum alloy. The sample is used as the anode and immersed in the bath liquid, and the stainless steel container with cooling system is used as the cathode. The current density is controlled at 35A / dm 2 , the constant-current...

Embodiment 2

[0030] Raw material preparation: 5g / L Na 2 SiO 3 ?9H 2 O, 8g / L Na 2 MnO 4 ?2H 2 O, 8g / L NaF, 3g / L NaOH, 3g / L Bi 2 o 3 , the solvent is deionized water, the sample is ZL101A cast aluminum alloy of 50mm×20mm×3mm, polished smooth by #800, #1000, #1500 sandpaper step by step, cleaned with deionized water and dried.

[0031] Material preparation: According to the above composition, Na 2 SiO 3 ?9H 2 O, Na 2 MnO 4 ?2H 2 O, NaF, NaOH and Bi 2 o 3 Add deionized water to make a bath, ultrasonically vibrate the bath for 15 minutes, then magnetically stir for 15 minutes, then add to the micro-arc oxidation electrolytic cell, and stir it.

[0032] A 20kW DC pulse micro-arc oxidation device is used to perform micro-arc oxidation on the surface of cast aluminum alloy. The sample is used as the anode and immersed in the bath liquid, and the stainless steel container with cooling system is used as the cathode. The current density is controlled at 35A / dm 2 , the constant-current ...

Embodiment 3

[0034] Raw material preparation: 10g / L Na 2 SiO 3 ?9H 2 O, 5g / L Na 2 MnO 4 ?2H 2 O, 7g / L NaF, 6g / L NaOH, 5g / L Bi 2 o 3 , the solvent is deionized water, the sample is ZL101A cast aluminum alloy of 50mm×20mm×3mm, polished smooth by #800, #1000, #1500 sandpaper step by step, cleaned with deionized water and dried.

[0035] Material preparation: According to the above composition, Na 2 SiO 3 ?9H 2 O, Na 2 MnO 4 ?2H 2 O, NaF, NaOH and Bi 2 o 3 Add deionized water to make a bath, ultrasonically vibrate the bath for 20 minutes, then magnetically stir for 10 minutes, then add to the micro-arc oxidation electrolytic cell, and stir it.

[0036]A 20kW DC pulse micro-arc oxidation device is used to perform micro-arc oxidation on the surface of cast aluminum alloy. The sample is used as the anode and immersed in the bath liquid, and the stainless steel container with cooling system is used as the cathode. The current density is controlled at 35A / dm 2 , the constant-current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com