A process for preparing high-purity gardenia blue pigment of different hues

A high-purity gardenia blue pigment technology, which is applied in the field of preparing high-purity gardenia blue pigments with different hues, can solve the problems of low product quality and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

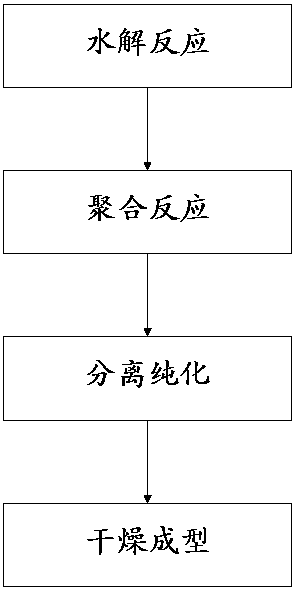

[0026] see figure 1 , the process is as follows:

[0027] 1) Hydrolysis reaction. Take 200g of geniposide (content 80%) into the reactor, add 414g of water, stir to completely dissolve the geniposide in the water, adjust the pH to 4.5 with dilute hydrochloric acid, and heat the solution to 50°C in a 50°C water bath while stirring. ℃; then add 6.87g β-glucosidase, react for 4.5 hours, adjust the pH to 8.0 by adding NaOH;

[0028] 2) Polymerization. Feed compressed air into the reaction kettle with a flow rate of 50L / min; increase the temperature of the water bath to 70°C, add 24.7g of sodium glutamate at the same time, and carry out a color reaction. During the reaction, carry out moderate water replenishment. After 2 hours of reaction, stop ventilation ; The experimental data are shown in Table 1.

[0029] The experimental data in the table 1 embodiment 1

[0030] Response time / hour

R1

R2

Compressed air flow / L / min

1

2.61

2.77

50

2 ...

Embodiment 2

[0034] see figure 1 , the process is as follows:

[0035] 1) Hydrolysis reaction. Take 200g of geniposide (content 80%) into the reaction kettle, add 410g of water, stir to completely dissolve the geniposide in the water, adjust the pH to 4.3 with dilute hydrochloric acid, and heat the solution to 50°C in a 50°C water bath while stirring. ℃; then add 6.87g β-glucosidase, react for 4.5 hours, adjust the pH to 8.1 by adding NaOH;

[0036] 2) Polymerization. Introduce compressed air into the reaction kettle with a flow rate of 50 L / min, increase the temperature of the water bath to 70°C, and add 24.7 g of sodium glutamate at the same time to carry out a color reaction. The reaction lasts for 5 hours. The experimental data are shown in Table 2.

[0037] The experimental data in the table 2 embodiment 2

[0038] Response time / hour

R1

R2

compressed air flow

1

2.67

2.81

50

2

3.80

3.08

50

3

4.21

2.92

50

4

3.85...

Embodiment 3

[0042] see figure 1 , the process is as follows:

[0043] 1) Hydrolysis reaction. Take 900g of geniposide (content 80%) into the reaction kettle, add 9540g of water, stir to completely dissolve the geniposide in the water, adjust the pH to 4.4 with dilute hydrochloric acid, heat it to 50°C in a water bath, and keep it at a constant temperature; then add 114g of β-fiber Sulfase, stirring for hydrolysis reaction for 5 hours, after the reaction, adjust the pH to 8.2 with NaOH solution;

[0044] 2) Polymerization. Add 315g of sodium glutamate and 100g of phenylalanine, and at the same time pass compressed air at a flow rate of 200L / min; after 1 hour of reaction, the ventilation rate is reduced to 100L / min; after 2 hours of reaction, stop the ventilation; after 2.5 hours of reaction Afterwards, cool down with condensing circulating water, stop reaction; Obtain the gardenia blue reaction solution 11.42kg of R1=3.95, R2=2.79, E600=8.98;

[0045] 3) Through refining, you can get: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com