Equipment for removing aflatoxin from peanut oil by using activated carbon

A technology of aflatoxin and peanut oil, which is applied in the direction of fat production, fat oil/fat refining, etc., can solve the problems of low efficiency of biological enzymatic hydrolysis, residual organic solvent of peanut oil, and insignificant effect, so as to retain taste and nutrition and reduce activated carbon Slag, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

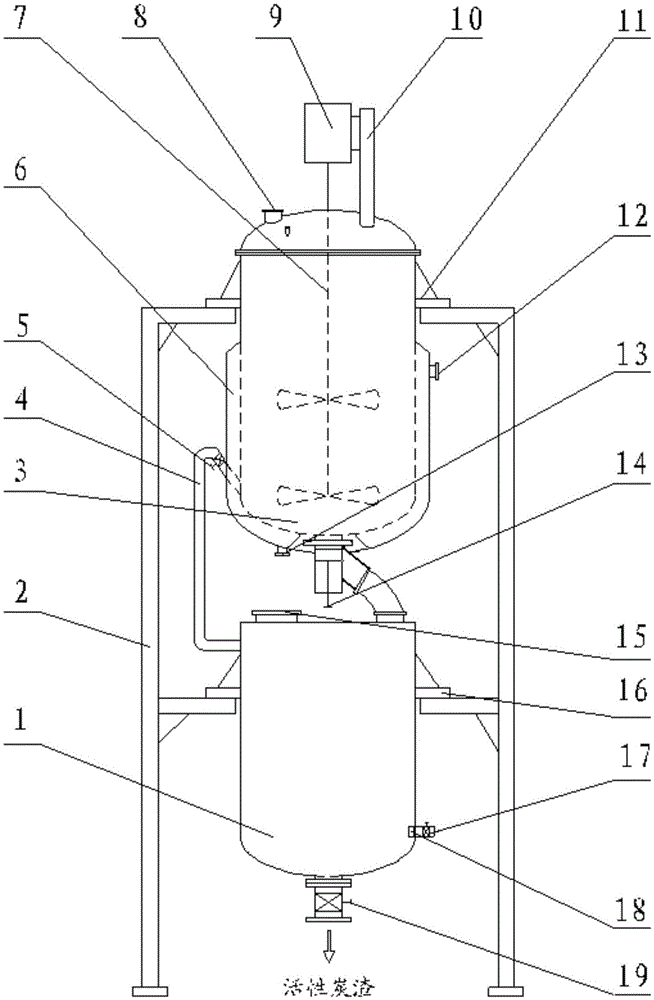

[0026] A device for removing aflatoxin in peanut oil with activated carbon, characterized in that it is provided with a reaction tank 3, a static tank 1 and a support frame 2; the reaction tank 3 and the static tank 1 are respectively fixed on the support of the support frame 2 On the supporting ear of the column, the bottom of the reaction tank 3 is connected with the upper end cover of the static tank 1 through a flange;

[0027] The reaction tank 3 is provided with a feeding port 8, an agitator 7, and a discharge valve A14, and the jacket 6 of the reaction tank 3 is provided with a hot water outlet 12 and a steam inlet 13; the top of the reaction tank 3 is provided with a driving device 9 and a fixed seat 10;

[0028] Described static tank 1 is provided with hand orifice 15, oil outlet valve 17, slag discharge valve 19; The slagging valve 19 is located at the bottom of the static tank 1;

[0029] The support frame 2 is provided with 4 support columns, and the middle and l...

Embodiment 2

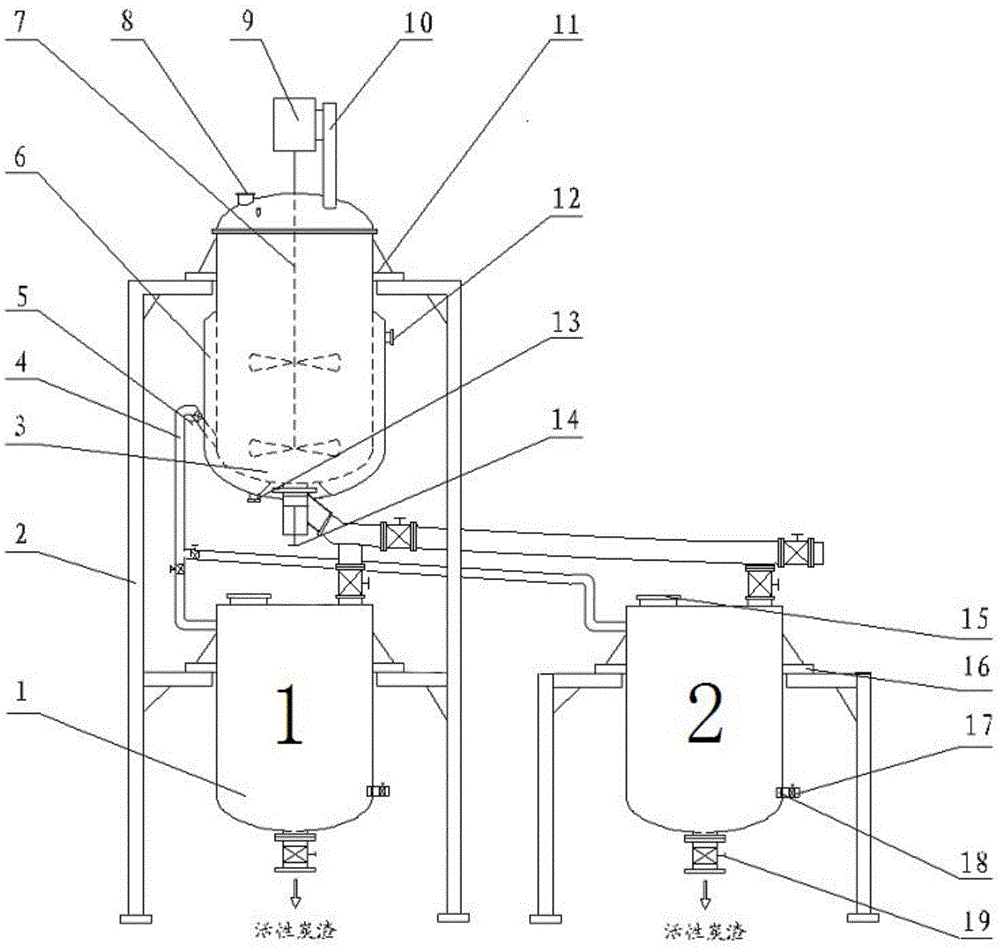

[0033] A device for removing aflatoxin in peanut oil with activated carbon, characterized in that it is provided with a reaction tank 3, a static tank 1 and a support frame 2; the reaction tank 3 and the static tank 1 are respectively fixed on the support of the support frame 2 on the supporting ears of the column;

[0034] The reaction tank 3 is provided with a feeding port 8, an agitator 7, and a discharge valve A14, and the jacket 6 of the reaction tank 3 is provided with a hot water outlet 12 and a steam inlet 13; the top of the reaction tank 3 is provided with a driving device 9 and a fixed Seat 10, the bottom of reaction tank 3 is provided with discharge valve A14 and connected with the upper end cover of static tank 1 by flange;

[0035] Described static tank 1 is provided with hand orifice 15, oil outlet valve 17, slag discharge valve 19; The slagging valve 19 is located at the bottom of the static tank 1;

[0036] The support frame 2 is provided with 4 support colum...

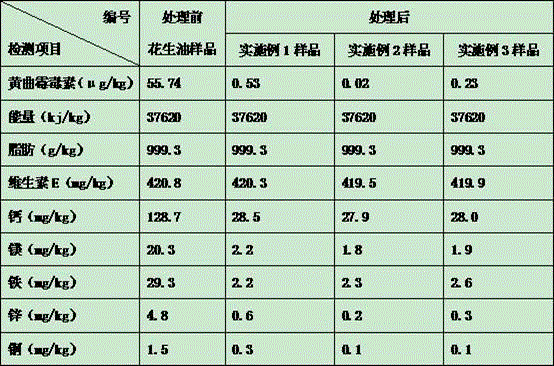

Embodiment 3

[0041] A device for removing aflatoxin in peanut oil with activated carbon, characterized in that it is provided with a reaction tank 3, a static tank 1 and a support frame 2; the reaction tank 3 and the static tank 1 are respectively fixed on the support of the support frame 2 on the supporting ears of the column;

[0042] The reaction tank 3 is provided with a feeding port 8, an agitator 7, and a discharge valve A14, and the jacket 6 of the reaction tank 3 is provided with a hot water outlet 12 and a steam inlet 13; the top of the reaction tank 3 is provided with a driving device 9 and a fixed Seat 10, the bottom of reaction tank 3 is provided with discharge valve A14 and connected with the upper end cover of static tank 1 by flange;

[0043]Described static tank 1 is provided with hand orifice 15, oil outlet valve 17, slag discharge valve 19; The slagging valve 19 is located at the bottom of the static tank 1;

[0044] The support frame 2 is provided with 3 support column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com