Building phase-change heat storage composite material used as light aggregate

A phase change heat storage and composite material technology, which is applied in the field of phase change heat storage material preparation, can solve the problems of easy leakage, difficult cement base, and poor packaging, and achieves easy leakage, small porosity, and difficulty in The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

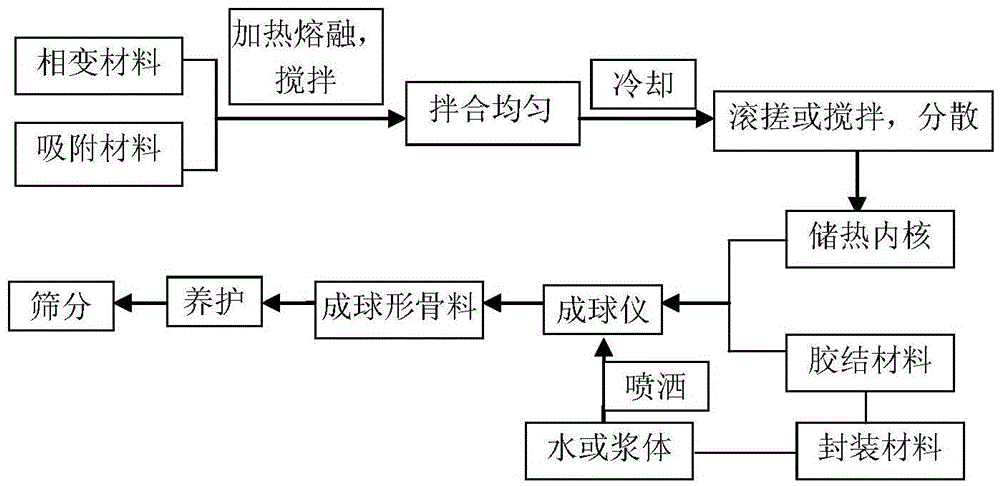

Method used

Image

Examples

Embodiment

[0026] The phase change material is made of liquid paraffin at 5°C and sliced paraffin at 58-60°C in a ratio of 1:2 to prepare a phase change material with a melting point of 28°C and a latent heat of phase change of 218J / g.

[0027] The encapsulation material adopts P·II42.5R cement and Class I fly ash mixed in proportions of 80% and 20% as the cementing material, and the ratio of water and encapsulation material is 0.15-0.25.

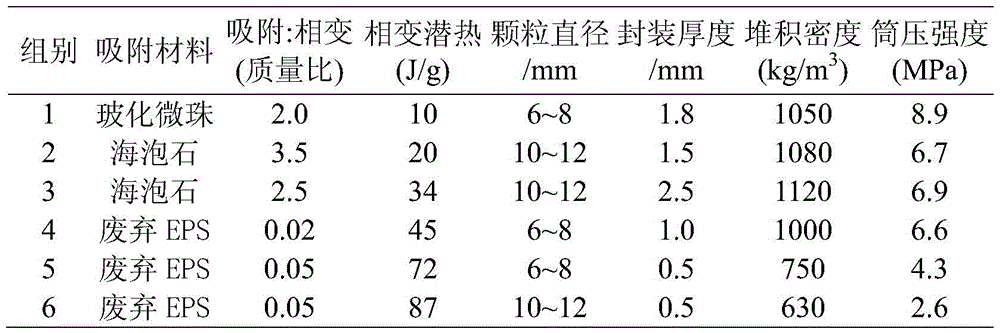

[0028] Adsorbent materials Group 1 used vitrified microbeads, Groups 2 and 3 used sepiolite, and Groups 4, 5 and 6 used waste EPS.

[0029] After 4 hours of molding, put it in an environment with a temperature of 20°C and a relative humidity greater than 90% for 7 days, and then put it in a steam curing room at 40°C for 24 hours. The measured results are shown in Table 1. The products are as follows: figure 1 shown.

[0030] Table 1 The ratio and performance of different phase change materials, adsorption materials, and packaging materials

[0031...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com