Acid-resistant and alkali-resistant light conveying belt

A light-duty conveyor belt, acid and alkali resistant technology, applied in the field of conveyor belts, can solve the problems of insufficient stability, poor anti-vibration performance and high safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

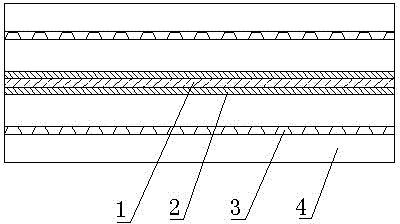

[0015] exist figure 1 Among them, the middle layer of acid and alkali resistant light conveyor belt is alkali-free glass fiber 1, and the two sides of alkali-free glass fiber 1 are aramid fiber layer 2, and the outer layer of aramid fiber layer 2 is a covering rubber layer 4 composed of epoxy resin material, and the outer layer of aramid fiber layer 2 is The cushioning layer that nylon polyester mesh cloth 3 is formed in is provided with the cushioning layer that covers rubber layer 4 on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com