An Intelligent Welding Seam System

An intelligent, welding torch technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of lag in adjustment mode, poor accuracy, large error, etc., and achieve the effect of improving welding efficiency and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

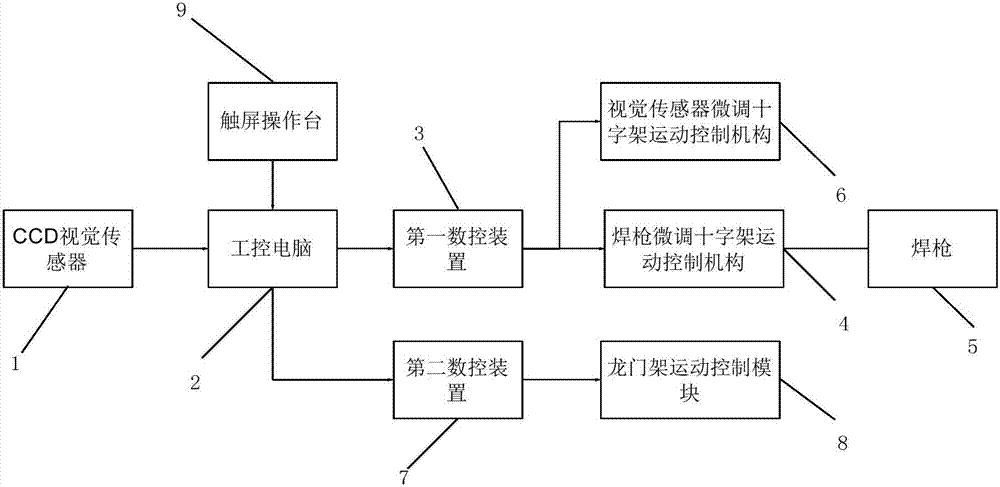

[0038] see figure 2 , which is a connection block diagram of the intelligent welding seam system of the present invention.

[0039] The invention provides an intelligent welding seam system, comprising a CCD visual sensor 1, an industrial computer 2, a first numerical control device 3, a welding torch fine-tuning cross movement control mechanism 4, a welding torch 5, a visual fine-tuning cross movement control mechanism 6, and a second numerical control device 7. Gantry motion control mechanism 8 and touch screen console 9.

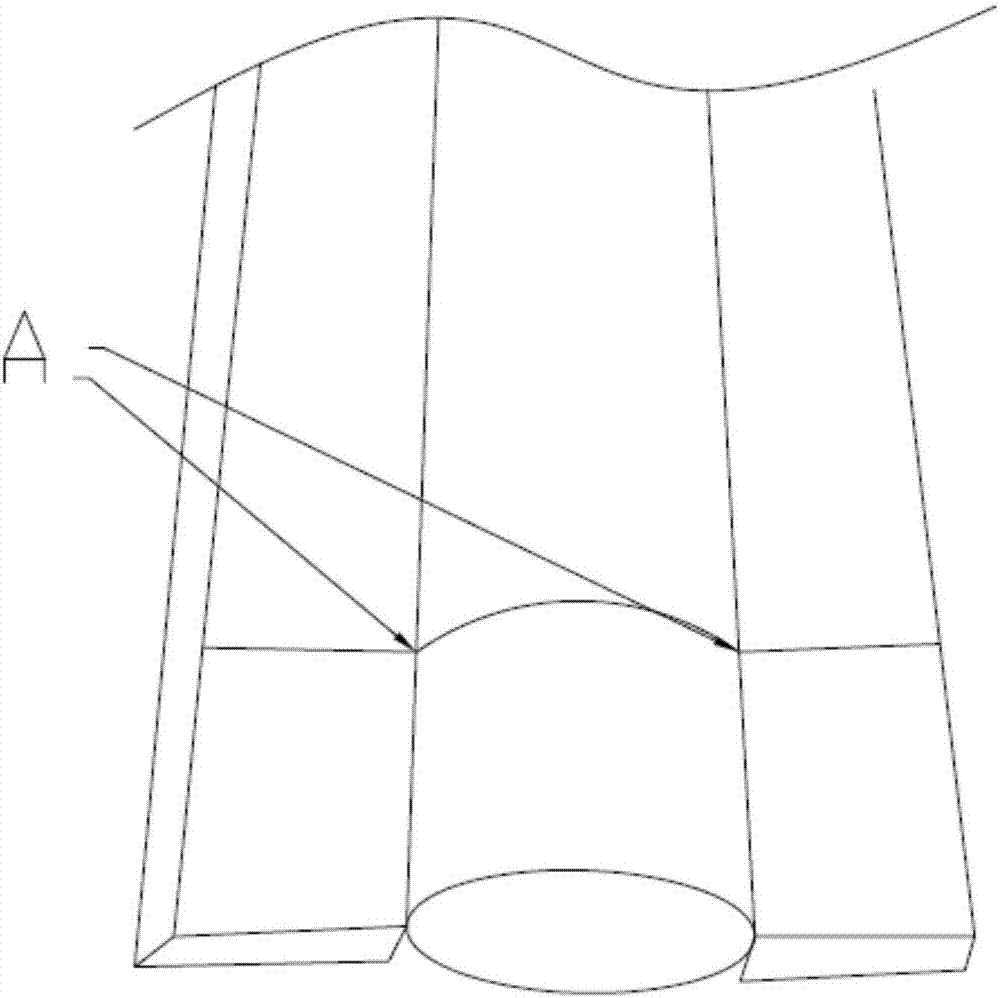

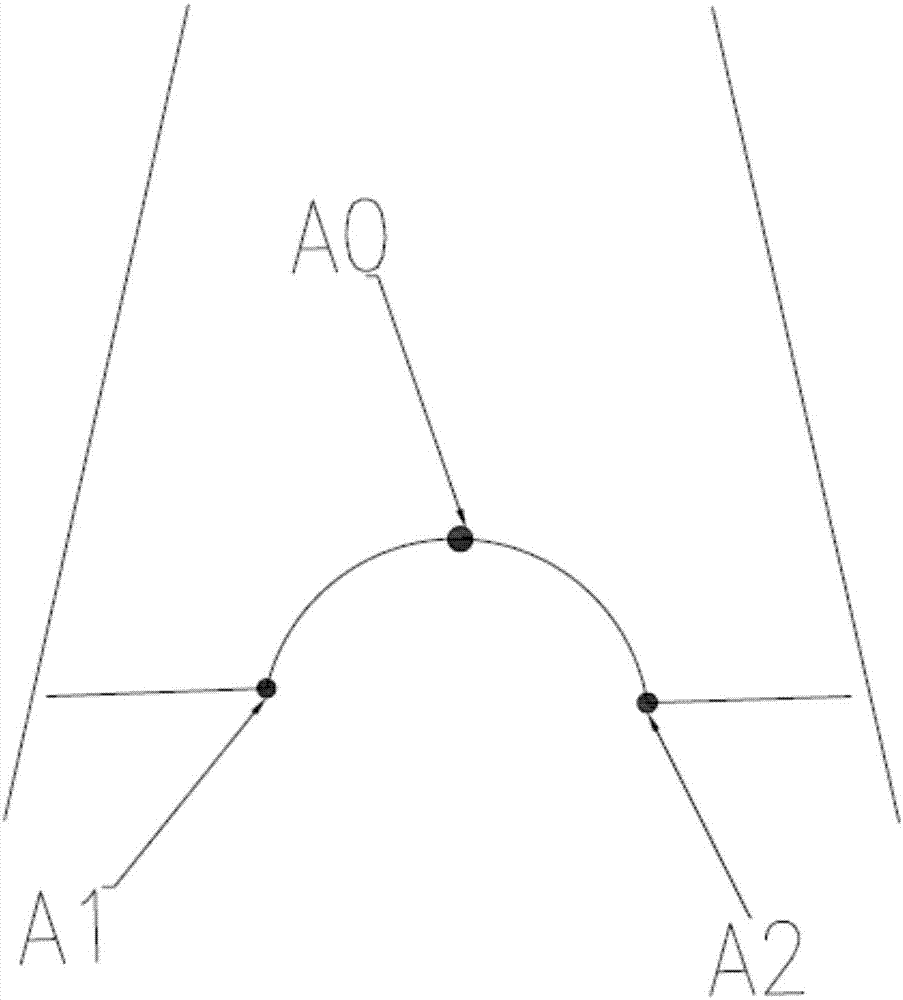

[0040] The CCD vision sensor 1 is used to scan the weld seam in real time, and send the scanning information to the industrial computer 2 . Please also see image 3 , which is a schematic diagram of a CCD vision sensor detecting a weld seam in the present invention. The CCD vision sensor 1 is located in the middle part A0 of the pipe or fin to be detected, and simultaneously detects the weld seam A1 and the weld seam A2 on both sides of the pipe or fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com