A method for preparing copper nanotubes embedded with copper oxide nanoparticles

A nanoparticle and copper oxide technology, applied in the field of nanomaterials, can solve the problems of inability to large-scale production, complex synthesis process, high cost of raw materials, etc., and achieve the effects of good product reproducibility, low cost of raw materials, and excellent cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] a Dissolve 0.2 g of cuprous chloride in 8 ml of oleylamine and stir for 1.5 hours to make it evenly mixed.

[0040] b Next, the above-mentioned homogeneously mixed solution was transferred into a 50 ml stainless steel reaction kettle, placed in a normal pressure oven, and the temperature was rapidly raised to 200 degrees Celsius, and stood for 3 hours.

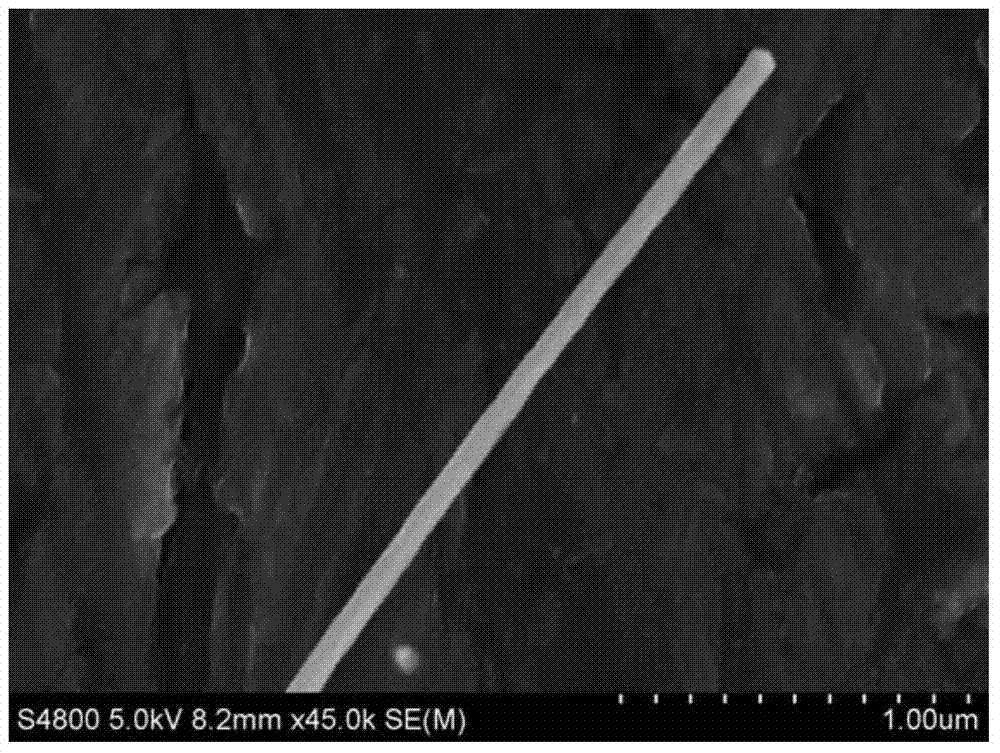

[0041] c After the reaction is completed, the color of the solution changes from yellow to red. At this time, the reaction kettle was taken out from the oven, rinsed with cold water and rapidly cooled to room temperature (25 degrees Celsius), and the product was washed three times with n-hexane and absolute ethanol respectively to obtain a pure copper nanowire product.

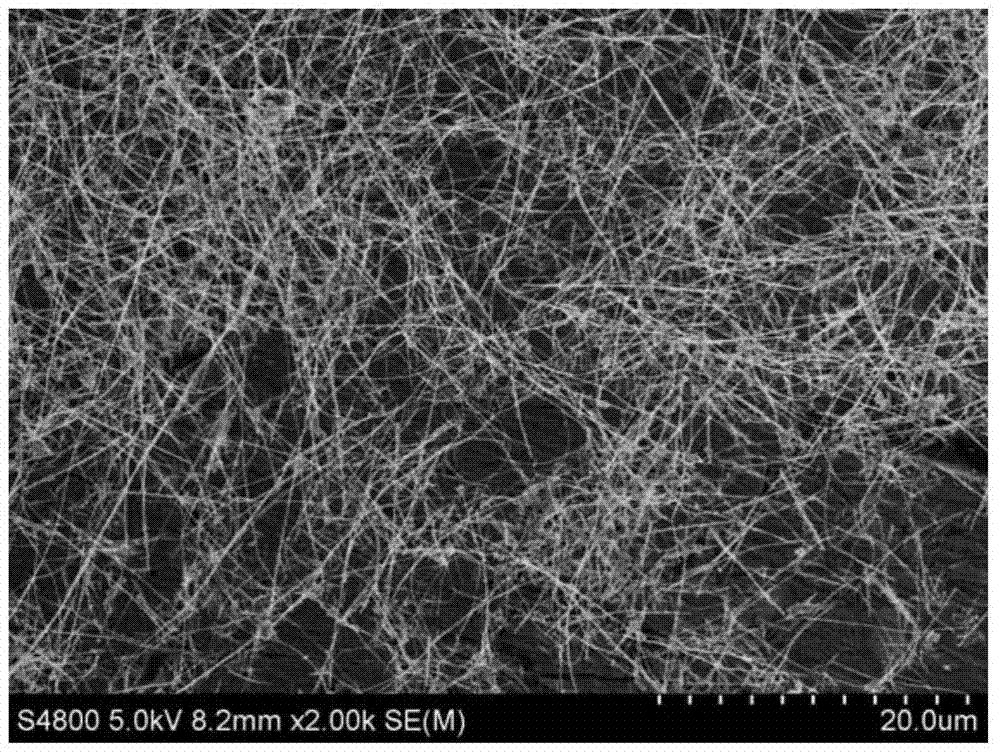

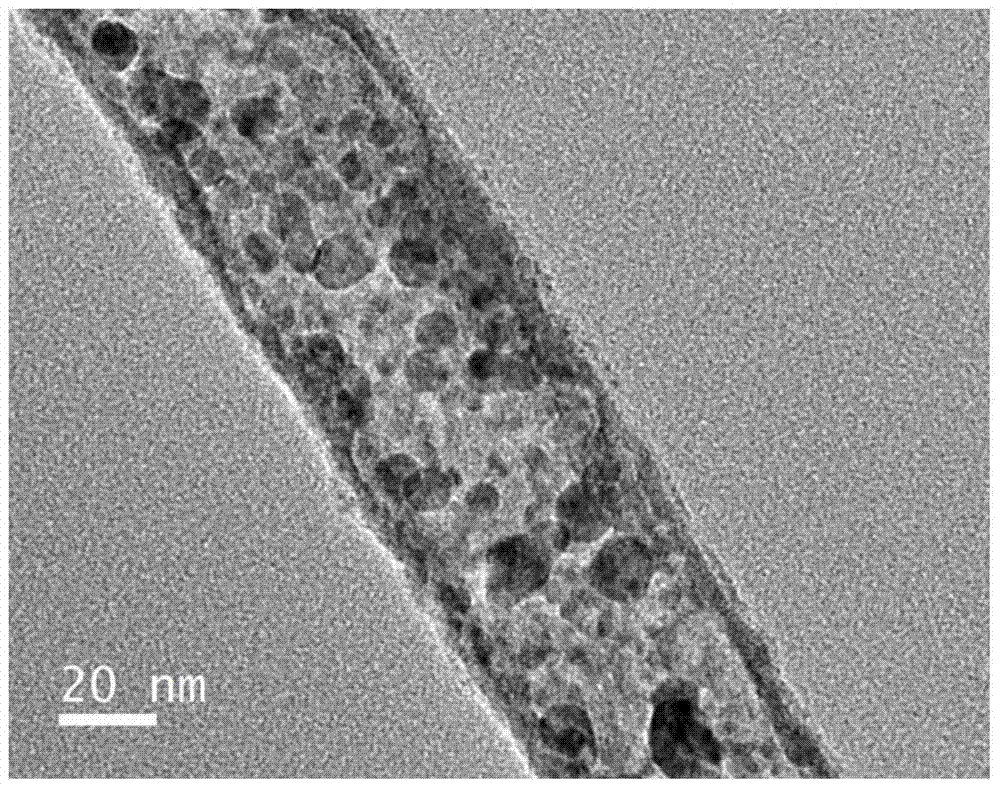

[0042]d Place the above product in a closed reaction vessel full of 75% humidity air, and oxidize it in a thermostat at 60 degrees Celsius for 4 hours. After the reaction is finished, copper oxide hollow nanofibers embedded with copper oxide nanopartic...

Embodiment 2

[0051] a Weigh 2 grams of cuprous chloride and dissolve it in 80 milliliters of oleylamine, stir for 2 hours to make it evenly mixed.

[0052] b. Transfer the above homogeneously mixed solution into a 500 ml stainless steel reaction kettle, and place it in an oven at 200 degrees Celsius for 4 hours.

[0053] c After the reaction is completed, the reaction kettle is taken out from the oven, rinsed with cold water for 10 minutes to make it rapidly cooled, and the precipitated product in the kettle is washed three times with n-hexane and absolute ethanol respectively to obtain a pure copper nanowire product.

[0054] d Place the above-mentioned washed and enriched product in a tubular heating furnace with adjustable temperature and humidity, rapidly heat up to 60 degrees Celsius at 15 degrees Celsius / minute, and continue to feed humid air with a humidity of 75%. 30 sccm, after aging for 5 hours, copper oxide hollow nanofibers embedded with copper oxide nanoparticles were obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com