Precoated sand mold for copper piece casting and copper piece casting method

A technology for coating sand and copper parts, which is applied in casting molding equipment, molds, mold components, etc., to achieve the effect of improving utilization rate, improving internal quality, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

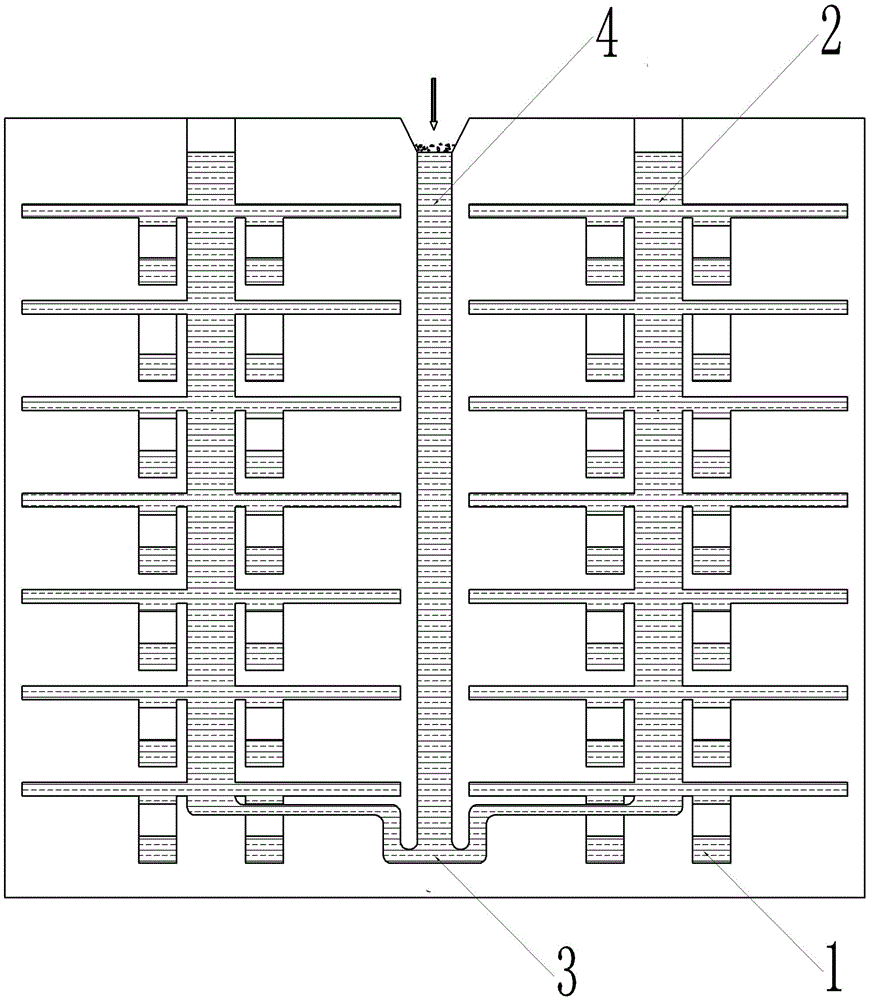

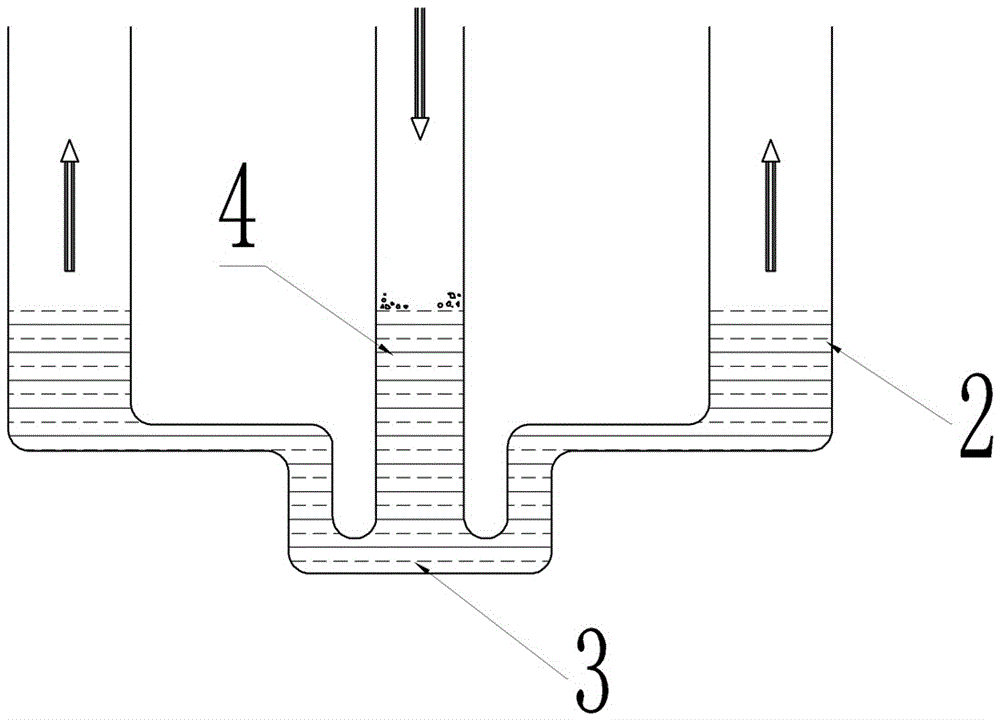

[0028] A coated sand mold for copper casting, see figure 2 , image 3 , including several casting cavities, two casting liquid channels, a slag-avoiding inner core and a sprue channel; the two casting liquid channels are distributed on both sides of the sprue channel, and the lower ends of the three are connected through the slag-avoiding inner core; The casting cavity is distributed around the casting solution channel and communicated with the casting solution channel; the position of the slag avoiding inner core is lower than the casting solution channel; the upper end of the sprue channel is higher than the casting cavity.

Embodiment 2

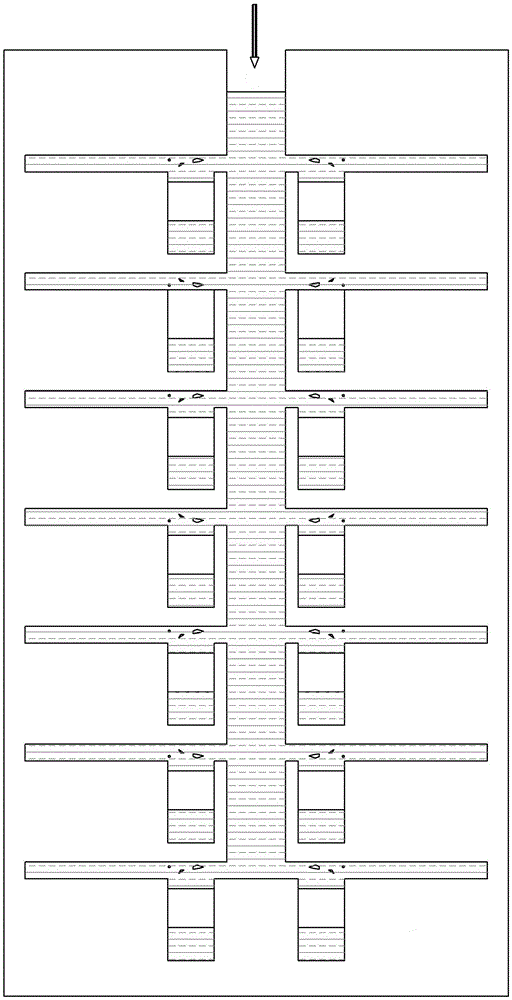

[0030] A film-coated sand mold for copper casting, including several casting cavities, a casting liquid channel, a slag-avoiding inner core and a sprue channel; the casting liquid channel and the sprue channel are arranged vertically, and the lower ends of the two It communicates through the slag-avoiding inner core; the casting cavity is distributed around the casting liquid channel and communicates with the casting liquid channel; the position of the slag-avoiding inner core is lower than the casting liquid channel; the upper end of the spout channel is higher in the casting cavity.

Embodiment 3

[0032] The method for casting copper parts using the coated sand mold of Example 1 includes the following steps (taking the isolation knife seat equipped with the ZW32 vacuum circuit breaker as an example):

[0033] Make a coated sand mold according to the structure, and then pour copper liquid. The casting temperature of pure copper is controlled at 1180°C. During casting, the flow control principle of slow first and then fast should be followed. After pouring is completed, cool and form, and remove the sand mold to make.

[0034] After finishing the finished product, carry out the following operations to further refine the product:

[0035] (1) Intermediate processing

[0036] After solidification and cooling, the sprue is removed, and the surface of the casting is sandblasted to obtain the blank of the tool seat;

[0037] (2) Cold extrusion molding

[0038] Put the blank of the tool seat that has been sandblasted on the surface into the hard metal inner core with a diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com