Sepiolite modification method and application of modified sepiolite to wastewater treatment

A technology of wastewater treatment and sepiolite, which is applied to the modification of sepiolite, and the application field of modified sepiolite in wastewater treatment, which can solve problems such as unsuitable for industrial production, not in line with environmental protection, and reduce modification costs , to achieve the effect of less energy consumption, high adsorption rate and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

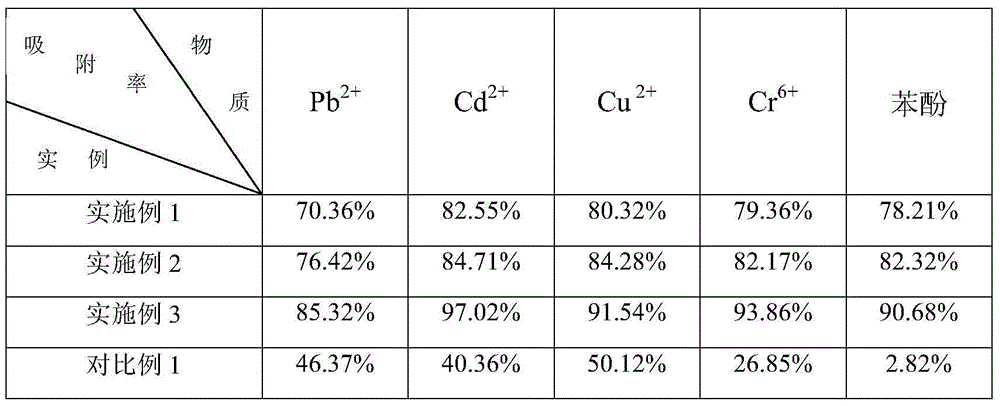

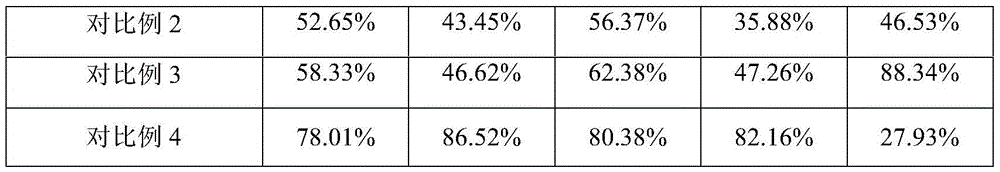

Examples

Embodiment 1

[0021] A modification method of sepiolite, comprising the steps of:

[0022] (1) adding 800ml concentration of 1.2mol / L hydrochloric acid solution to 100g sepiolite, controlling the temperature at 40°C, and processing for 4 hours to obtain acid-modified sepiolite;

[0023] (2) Add a solution made of 600g cellulose and 1.5mol ferric chloride to the above-mentioned acid-modified sepiolite, carry out hydrothermal reaction, the temperature is 200 ℃, and the time is 20 hours;

[0024] (3) Filtrate, wash, and then dry at 120° C. for 10 hours to obtain the modified sepiolite.

Embodiment 2

[0026] A modification method of sepiolite, comprising the steps of:

[0027] (1) Adding 600ml concentration of 2mol / L nitric acid solution to 100g sepiolite, controlling the temperature at 60°C, and processing for 6 hours to obtain acid-modified sepiolite;

[0028] (2) Add a solution made of 1500g cellulose and 2mol ferric chloride to the above-mentioned acid-modified sepiolite, carry out hydrothermal reaction, the temperature is 160 ℃, and the time is 30 hours;

[0029] (3) Filtrate, wash, and then dry at 120° C. for 10 hours to obtain the modified sepiolite.

Embodiment 3

[0031] A modification method of sepiolite, comprising the steps of:

[0032] (1) adding 1000ml concentration of 1.5mol / L hydrochloric acid solution to 100g sepiolite, controlling the temperature at 80°C, and processing for 5 hours to obtain acid-modified sepiolite;

[0033] (2) Add the solution that 1500g cellulose and 1.3mol ferric chloride and 0.7mol ferrous chloride are made into in above-mentioned acid-modified sepiolite, carry out hydrothermal reaction, temperature is 300 ℃, time is 20 hours;

[0034] (3) Filtrate, wash, and then dry at 120° C. for 10 hours to obtain the modified sepiolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com