Combined-type absorbent used for selectively absorbing SO2 and application of combined-type absorbent

A kind of SO2, composite technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of difficult management and maintenance, high operating costs, secondary pollution, etc., to achieve simple preparation process, high absorption efficiency, high absorption rate fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

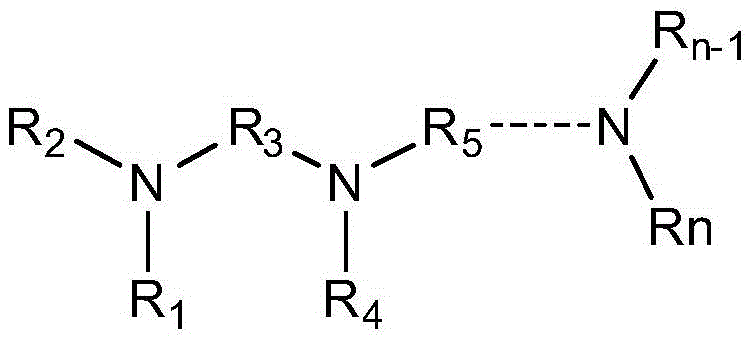

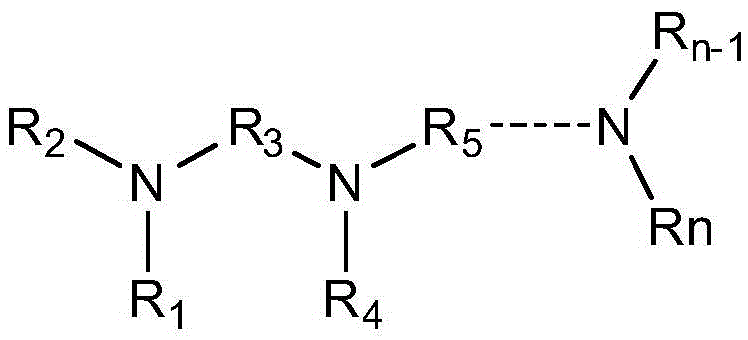

Method used

Image

Examples

Embodiment 1

[0028] Weigh 10.3 g of diethylenetriamine, add 11.0 g of 1,1,3,3-tetramethylurea, 5 g of water, and 3.7 g of concentrated sulfuric acid with a purity of 98% in sequence to prepare an absorbent. pure SO 2 gas and SO 2 The mixed gas with content of 8000ppm was subjected to absorption experiment at 30°C.

[0029] The absorbent for pure SO 2 The absorption capacity of gas is 30g, and the unit absorption capacity is 0.77g / g(SO 2 / absorbent). The desulfurization rate of the absorbent mixed gas reaches 99.1%.

Embodiment 2

[0043] Weigh 10.3 g of diethylenetriamine, add 11 g of N-methylpyrrolidone, 5 g of water, and 3.7 g of concentrated sulfuric acid with a purity of 98% in sequence to prepare an absorbent. pure SO 2 gas and SO 2 The mixed gas with content of 8000ppm was subjected to absorption experiment at 30°C.

[0044] The unit absorption is 0.76g / g(SO 2 / absorbent). The desulfurization rate of the absorbent mixed gas reaches 98.2%.

Embodiment 3

[0046] Weigh 9.8 g of tetraethylethylenediamine, add 11 g of N,N-dimethylacetamide, 5 g of water, and 4.2 g of concentrated sulfuric acid with a purity of 98% in sequence to prepare an absorbent. pure SO 2 gas and SO 2 The mixed gas with content of 8000ppm was subjected to absorption experiment at 30°C.

[0047] The unit absorption is 0.69g / g(SO 2 / absorbent). The desulfurization rate of the absorbent mixed gas reaches 97.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com