Semi-automatic stainless steel ring filter bag and production method thereof

A semi-automatic, stainless steel technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of cumbersome processing operations of stainless steel rings, so as to solve the cumbersome processing operations, reduce the probability of occurrence, and improve the connection firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

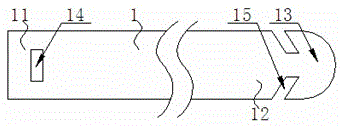

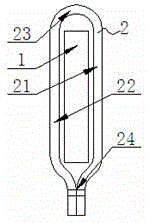

[0022] A semi-automatic stainless steel ring filter bag described in this embodiment includes: a stainless steel strip 1, the stainless steel strip 1 is made of high-elastic stainless steel, and the high-elastic stainless steel contains the following elements in mass percentage: carbon ≤ 0.15 %, manganese≤2.00%, silicon≤1.00%, phosphorus≤0.035%, sulfur≤0.03%, nickel 6.00%~10.00%, chromium 16.00%~19.00%, titanium 0.80%~1.20%, the balance iron;

[0023] The stainless steel strip 1 is a strip structure and includes a slot end 11 and a plug end 12, the plug end 12 of the stainless steel strip 1 is provided with a connecting plug 13, and the slot of the stainless steel strip 1 The end 11 is provided with a connection socket 14 . Two clamping grooves 15 are arranged between the connecting plug 13 and the stainless steel strip 1, the two clamping grooves 15 are symmetrical to the centerline of the length direction of the stainless steel strip 1, and the two clamping grooves 15 One e...

specific Embodiment 2

[0029] A semi-automatic stainless steel ring filter bag described in this embodiment includes: a stainless steel strip 1, the stainless steel strip 1 is made of high-elastic stainless steel, and the high-elastic stainless steel contains the following elements in mass percentage: carbon ≤ 0.15 %, manganese≤2.00%, silicon≤1.00%, phosphorus≤0.035%, sulfur≤0.03%, nickel 6.00%~10.00%, chromium 16.00%~19.00%, titanium 0.80%~1.20%, the balance iron;

[0030] The stainless steel strip 1 is a strip structure and includes a slot end 11 and a plug end 12, the plug end 12 of the stainless steel strip 1 is provided with a connecting plug 13, and the slot of the stainless steel strip 1 The end 11 is provided with a connection socket 14 . Two clamping grooves 15 are arranged between the connecting plug 13 and the stainless steel strip 1, the two clamping grooves 15 are symmetrical to the centerline of the length direction of the stainless steel strip 1, and the two clamping grooves 15 One e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com