No-killing and efficient feeding device for scorpions

A non-killing, scorpion-free technology, applied in animal husbandry, etc., can solve the problems of scorpions killing each other, cumbersome operation, and high feeding costs, and achieve the effects of avoiding killing each other, easy operation, and improving breeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

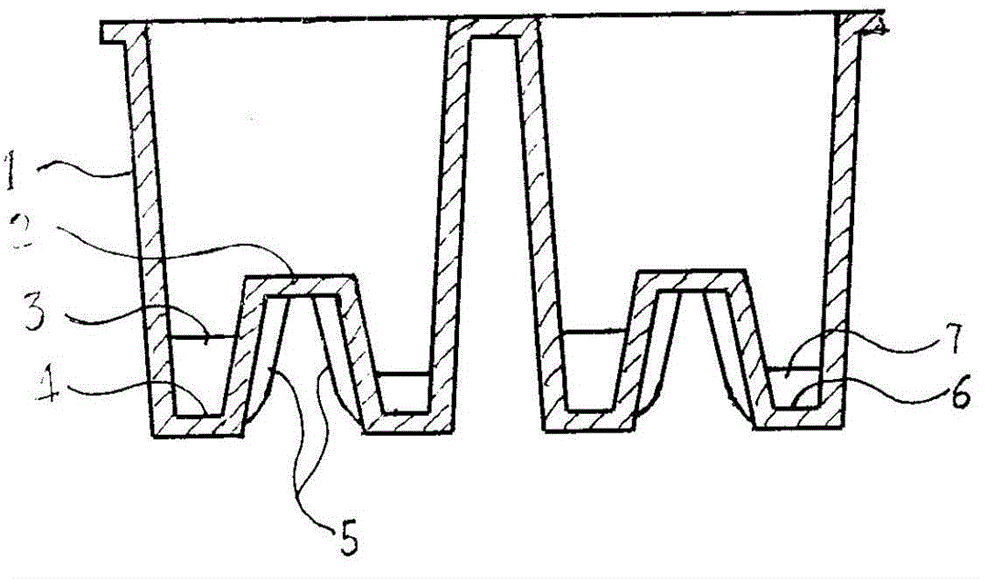

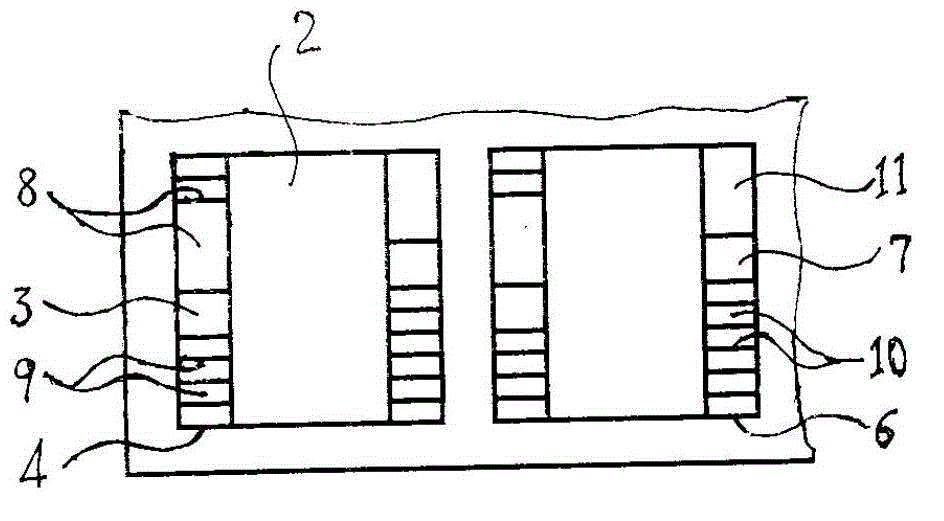

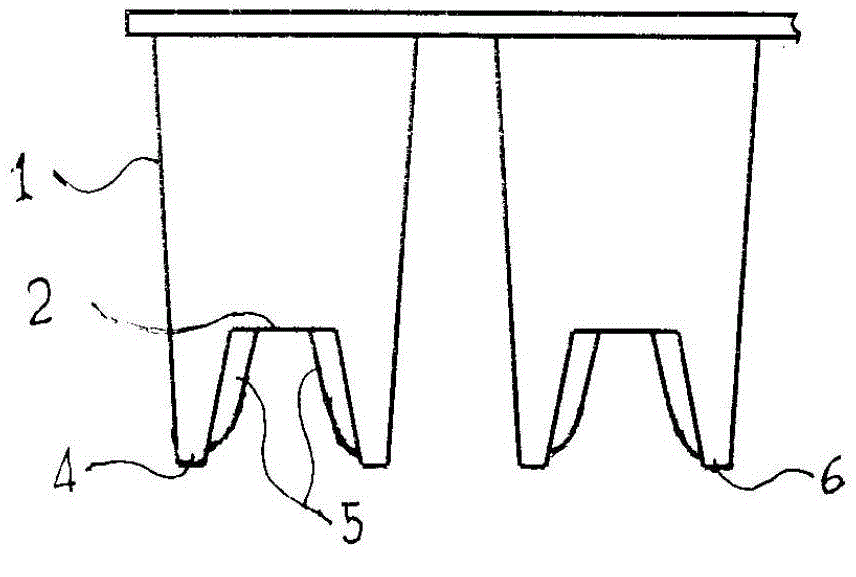

[0020] Such as figure 1 , 2 , 3, shown in 4, the scorpion of the present invention does not kill the high-efficiency raising device to have 20 scorpion raising units 1 (attached to each other) that are connected as a whole figure 1 , 2 , 3, and 4 only show the intercepted 2, or 5, 15, 20, 30, etc. can be connected into a group to form a whole), each scorpion breeding unit 1 has an isolation wall, and each scorpion breeding unit 1 The lower part of the body is provided with scorpion area 2, moisturizing area 4, and feed insect area 7, and scorpion area 2 is arranged between moisturizing area 4 and feed insect area 6, and the bottom surface of scorpion area 2 is higher than the bottom surface of moisturizing area 4 and feed insect area 6 .

[0021] The feed worm area 6 includes a feed worm stay area 11 and a feed worm pass area 10. A feed worm pass port is provided on the bottom surface of the feed worm pass area 10, and a delay is provided between the feed worm stay area 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com