Caking soybean residue cat litter

A technology of bean dregs and cat litter, applied in animal houses, applications, animal husbandry, etc., can solve the problems of loose texture, poor odor absorption, etc., and achieve uniform humidity, kill bacteria, good water absorption and agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

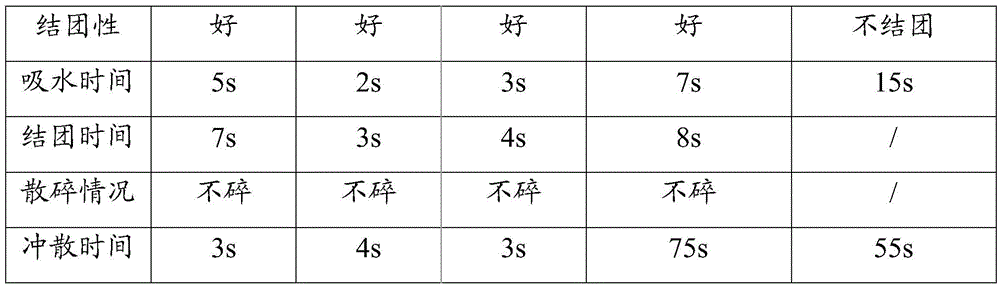

Embodiment 1

[0016] Embodiment 1: Weigh the raw materials according to the following ratio: 32kg bean dregs, 14kg bentonite, 2.0kg modified corn starch, 0.5kg guar gum, 0.6kg silicon dioxide, 2.5kg maltodextrin, 0.3kg green tea powder, activated carbon 1.5, cottonseed 0.05kg, chitosan 0.05kg, water 10kg.

[0017] Add okara, bentonite, modified corn starch, guar gum, silicon dioxide and other powdered raw materials into the mixer, stir evenly, and then spray water while stirring until the raw materials are uniform. The mixed raw materials are extruded and granulated with a 350-type granulator, and the length of the cat litter particles is set to 5mm and the diameter is 3.0mm. Put the granulated cat litter into the DWKX-D drying box for microwave drying at 35°C-40°C to get the final cat litter with a moisture content of 8%-12%, and then sieve it out with a special sieve after drying broken particles. The qualified cat litter is packaged and sold.

[0018] The cat litter described in this ...

Embodiment 2

[0019] Embodiment 2: Weigh the raw materials according to the following ratio: 28kg bean dregs, 16kg bentonite, 2.0kg modified corn starch, 0.6kg guar gum, 0.4kg silicon dioxide, 2.5kg maltodextrin, 0.4kg green tea powder, activated carbon 1.0, chitosan 0.05kg, Houttuynia cordata 0.05kg, water 10kg.

[0020] Add okara, bentonite, modified corn starch, guar gum, silicon dioxide and other powdered raw materials into the mixer, stir evenly, and then spray water while stirring until the raw materials are uniform. The mixed raw materials are extruded and granulated with a 350-type granulator, and the length of the cat litter particles is set to 8mm and the diameter is 4.0mm. Drying: Put the cat litter into the DWKX-D drying box for microwave drying at 50-60°C, and then sieve it after drying to remove particles whose particle size does not meet the standard.

[0021] The cat litter described in this embodiment clumped quickly, and the time to disperse it with water was longer than ...

Embodiment 3

[0022] Embodiment 3: Weigh the raw materials according to the following ratio: 30kg bean dregs, 15kg bentonite, 1.5kg modified corn starch, 0.5kg guar gum, 0.5kg silicon dioxide, 2.5kg maltodextrin, 0.2kg green tea powder, activated carbon 1.5, Rosin 0.05kg, Houttuynia cordata 0.05kg, Water 10kg.

[0023] Put the modified corn starch, guar gum, silicon dioxide, maltodextrin, green tea powder, activated carbon, rosin, and houttuynia cordata into a blender and stir evenly, then add water to make a paste mixture. Stir the bean dregs and bentonite remaining from making tofu evenly, then gradually add the mixing slurry and stir until a uniform mixture is obtained and stop stirring. The mixture is then added to a 350-type granulator for extrusion granulation. The length of the cat litter particles is set at 6 mm and the diameter is 3.0 mm. Put the cat litter particles into the DWKX-D drying oven for microwave drying at 40°C-50°C to obtain particles with a water content of 6%-8%. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com