Yttrium manganate film step low energy consumption resistive variable memory and its preparation and use method

A resistive variable memory, low energy consumption technology, applied in the direction of electrical components, etc., to achieve the effect of reducing noise, improving storage density, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

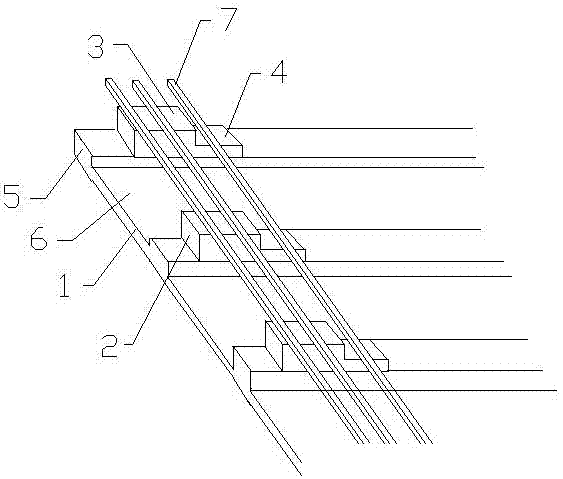

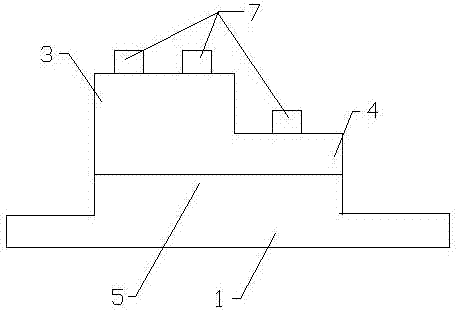

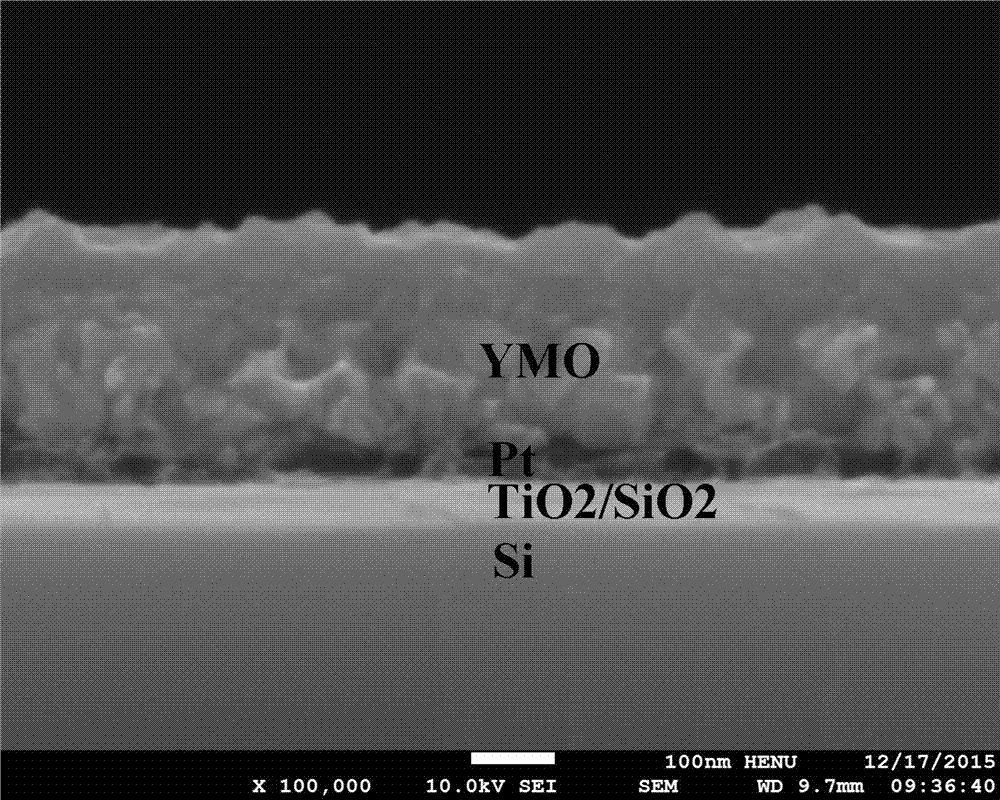

[0041] like figure 1 and figure 2 As shown, the YMO thin film step low energy consumption resistive memory of the present invention includes Pt / TiO 2 / SiO 2 / Si composite substrate layer 1 and set on Pt / TiO 2 / SiO 2 The YMO thin film step layer 2 on the upper surface of the / Si composite substrate layer 1, the YMO thin film step layer 2 includes a YMO thin film thick layer 3 and a YMO thin film layer 4, and the upper surface of the YMO thin film step layer 2 is provided with a metal upper electrode layer, Pt / TiO 2 / SiO2 The Pt layer in the middle layer of the / Si composite substrate is used as the lower electrode layer, and the YMO thin film step layer 2 is arranged between the metal upper electrode layer and the lower electrode layer.

[0042] In the present invention, Pt / TiO 2 / SiO 2 The Pt layer in the / Si composite substrate layer 1 offers multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com