Vacuum arc-extinguishing chamber

A vacuum interrupter and arc interrupter technology, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve problems such as temperature, air pressure rise, breakage, and cabinet deformation in high-voltage equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

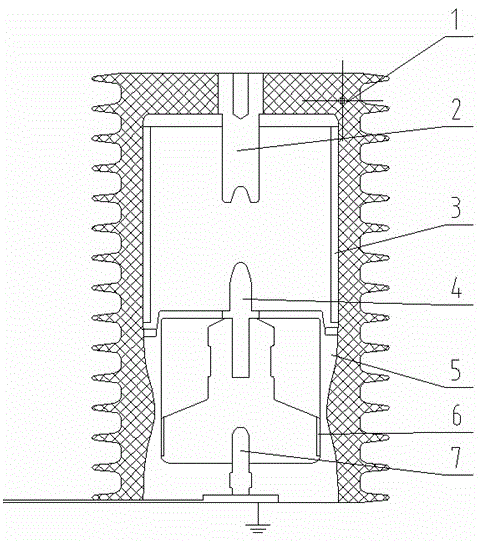

[0016] as attached figure 1 As shown, the vacuum interrupter composed of static contact 2, arc extinguishing chamber ceramic shell 3, moving contact 4, grounding contact 5, wristband contact finger 6, and micro gas generator 7, its manufacturing method includes the following step:

[0017] 1) Install the static contact 2 on the upper part of the ceramic shell 3 of the arc extinguishing chamber, and install the strap contact finger 6 in the groove of the moving contact 4;

[0018] 2) Install the grounding contact 5 to ensure that the moving contact 4 and the grounding contact 5 are connected;

[0019] 3) Install the moving contact 4 and the grounding contact 5 installed inside at one end of the ceramic shell 3 of the arc extinguishing chamber;

[0020] 4) The miniature gas generator 7 is installed on the grounding contact 5 and aligned with the hole on the bottom of the moving contact 4; 5) The part where the ceramic shell 3 of the arc extinguishing chamber contacts the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com