Cobalt selenide/nitrogen-doped carbon composite material and preparation method and application therefor

A technology of nitrogen-doped carbon and composite materials, applied in nanotechnology for materials and surface science, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problem of reduced stability and achieve excellent conductivity , good repeatability, good mesoporous structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

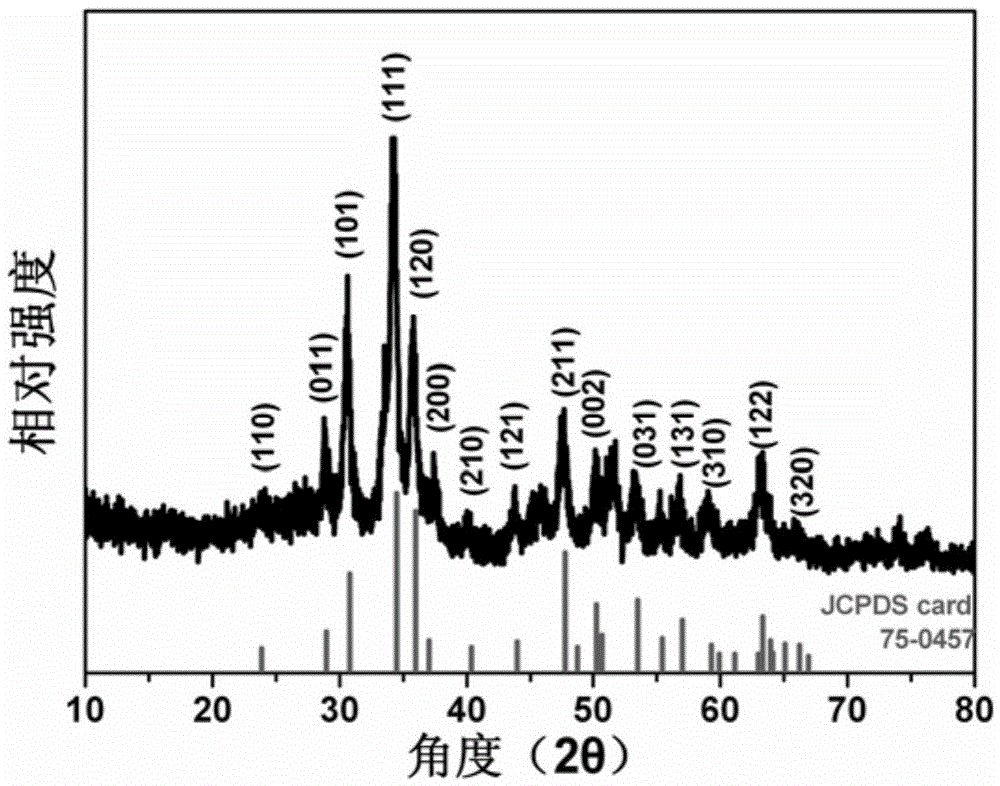

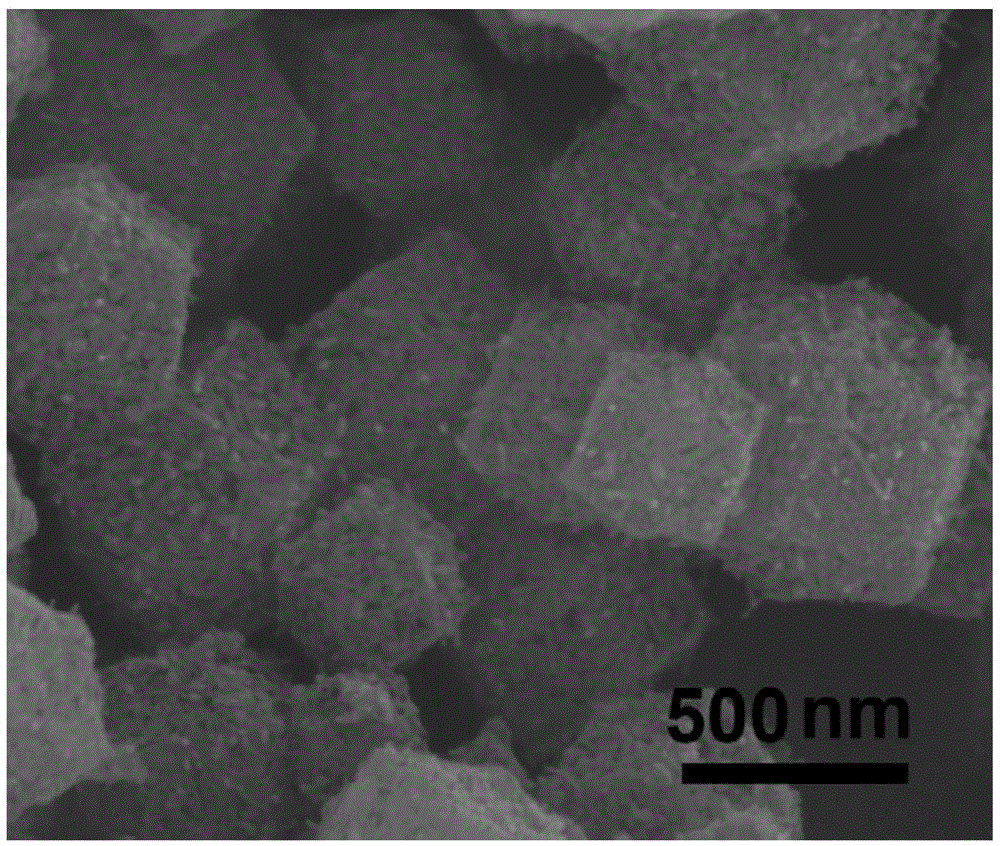

[0031] Double-shell cobalt selenide (CoSe 2 ) / Nitrogen-doped carbon composites

[0032] The cobalt nitrate hexahydrate of 4mmol is joined in the 200mL methanol that contains 20mmol dimethylimidazole, after mixing uniformly, leave standstill for 24 hours; The precipitate ZIF-67 obtained is centrifuged and dried, and the dry product and selenium powder are mixed at 1: The mass ratio of 1 is mixed; the resulting mixture is calcined at a temperature of 600 degrees Celsius for 4 hours under an argon atmosphere to obtain cobalt selenide (CoSe) with a double-shell structure. 2 ) / nitrogen-doped carbon composites.

[0033] The phase of the product was characterized by Rigaku D / max2500 X-ray diffractometer, the elements contained in the product were analyzed by ESCALAB250XiX photoelectron spectrometer from Thermo Fisher Scientific, and the morphology of the product was characterized by NovaNanoSEM230 scanning electron microscope , The internal structure of the product was characterize...

Embodiment 2

[0040] Cobalt selenide (CoSe 2 ) / Nitrogen-doped carbon composites

[0041] Add 4mmol of cobalt nitrate hexahydrate to 200mL of methanol containing 20mmol of dimethylimidazole, mix well and let stand for 24 hours; centrifuge and dry the obtained precipitate, and dry the product and selenium powder at a mass ratio of 1:1 than mixing; the resulting mixture was calcined at a temperature of 300 degrees Celsius for 4 hours under an argon atmosphere to obtain cobalt selenide (CoSe 2 ) / nitrogen-doped carbon composites.

Embodiment 3

[0043] Preparation of Large Size Cobalt Selenide (CoSe) / Nitrogen Doped Carbon Composite

[0044] Add 1 mmol of cobalt nitrate hexahydrate to 100 mL of methanol containing 5 mmol of dimethylimidazole, mix well and let stand for 24 hours; centrifuge and dry the obtained precipitate, and mix the dried product and selenium powder at a mass ratio of 1:1 ratio mixing; the resulting mixture was calcined at a temperature of 600 degrees Celsius for 4 hours under an argon atmosphere to obtain a cobalt selenide (CoSe) / nitrogen-doped carbon composite material.

[0045] The phase of the product was characterized by Rigaku D / max2500 X-ray diffractometer, and the morphology of the product was characterized by NovaNanoSEM230 scanning electron microscope.

[0046] Figure 6 Be the X-ray powder diffraction figure of the product of embodiment 3, the result shows that product is a cobalt selenide phase;

[0047] Figure 7 It is the SEM picture of the product of Example 3, it can be seen that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com