A three-stage surface plasmon lens

A surface plasmon, three-stage technology, applied in the field of ion polariton, can solve the problems of not fully utilizing the circular grating structure, inconvenient practical application, and low excitation efficiency of surface plasmon polariton, so as to avoid alignment Problems, Optimizing Size, Effects of Increasing Numerical Aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

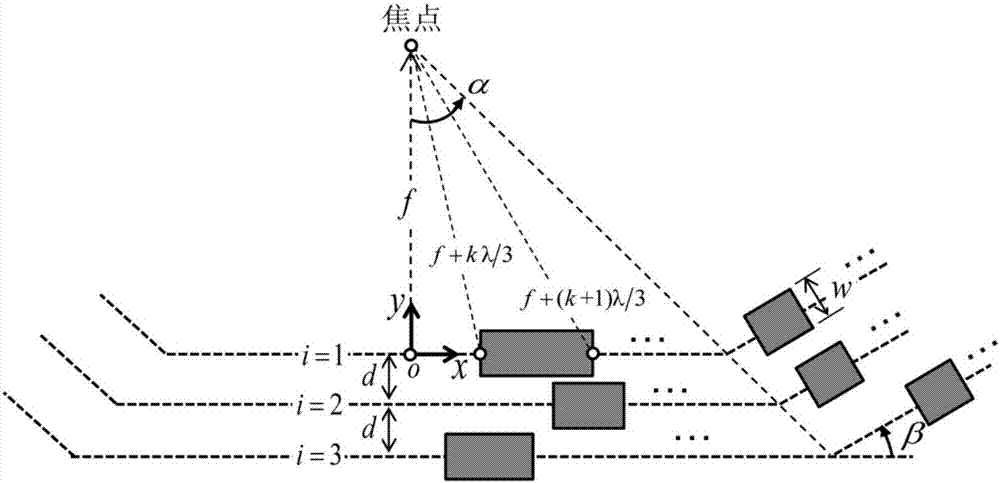

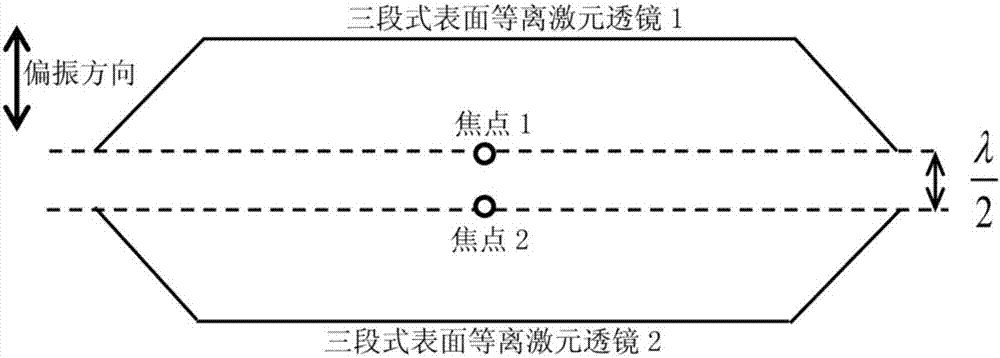

[0023] see figure 1 , the present invention consists of three layers of rectangular grooves 2 etched on the metal surface 4, under the illumination of linearly polarized light 1 incident perpendicular to the metal surface 4, a smaller-sized surface plasmon focus 3 that breaks through the diffraction limit will be formed , the width W of the rectangular groove 2 is λ / 2, where λ is the wavelength of the surface plasmon (see figure 2 ), the central position of each layer of grooves is distributed on three line segments, for the i-th layer (i=1,2,3), its trajectory is given by the following piecewise function:

[0024]

[0025] Among them, f is the focal length, d=2λ / 3 is the layer spacing of the horizontal line segment, α and β are two parameters that need to be optimized, and their meanings can be found in figure 2 . The signs "+" and "-" in fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com