Adsorption concentration-preheating catalytic combustion system and purification method for purifying paint exhaust gas from automobiles and related fields

A catalytic combustion and exhaust gas technology, applied in the direction of combustion methods, chemical instruments and methods, combustion types, etc., can solve the problems of harmful intermediate products, high concentration of organic waste gas, explosion, etc., achieve accurate gas temperature, stable purification efficiency, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

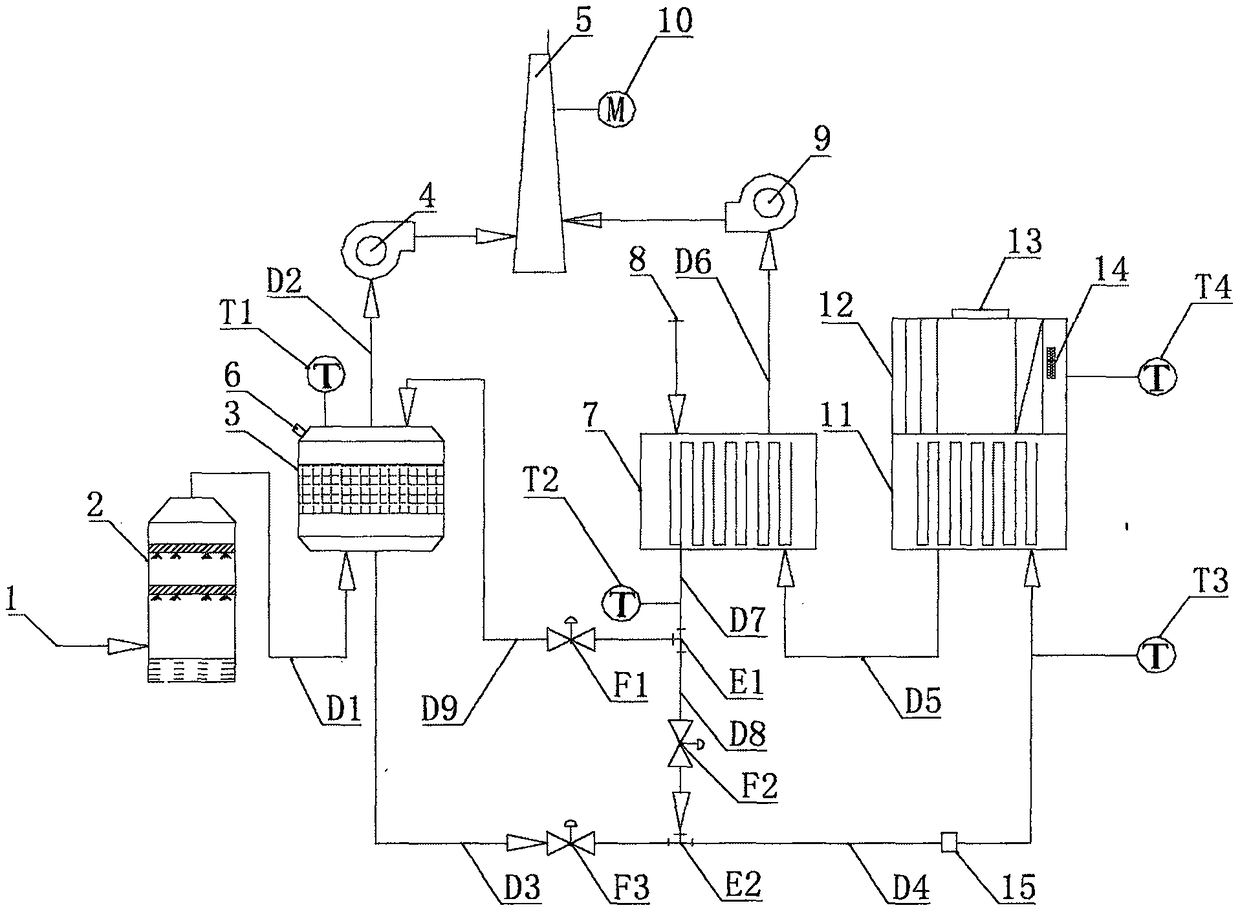

[0042] The present application will be further described below in conjunction with the accompanying drawings and specific implementation methods, but the protection scope of the present application is not limited to the content described.

[0043] Such as figure 1 As shown, this application is applicable to the adsorption concentration + preheating catalytic combustion device for purifying paint exhaust gas of automobiles and related fields, mainly including: wet filter 2, activated carbon adsorption device 3, heat exchanger 7 and heat exchanger 11, catalytic Combustion device 12, auxiliary electric heating device 14, electric air valves F1-F3, temperature detectors T1-T4, online monitor 10, frequency conversion fans 4 and 9, supplementary cooling air port 6, explosion-proof port 13, sampling port 15, tee Pipe E1-2, pipe D1-9, exhaust cylinder 5;

[0044] Wherein, the waste gas air inlet 1 is arranged on the wet filter 2; the wet filter 2 is connected to the activated carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com