A kind of architectural hollow brick and its manufacturing method

A technology of hollow bricks and buildings, applied in the direction of building materials, etc., can solve the problems of poor compressive performance of hollow bricks, easy collapse and damage of hollow bricks, and achieve the effect of avoiding moisture, avoiding collapse and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

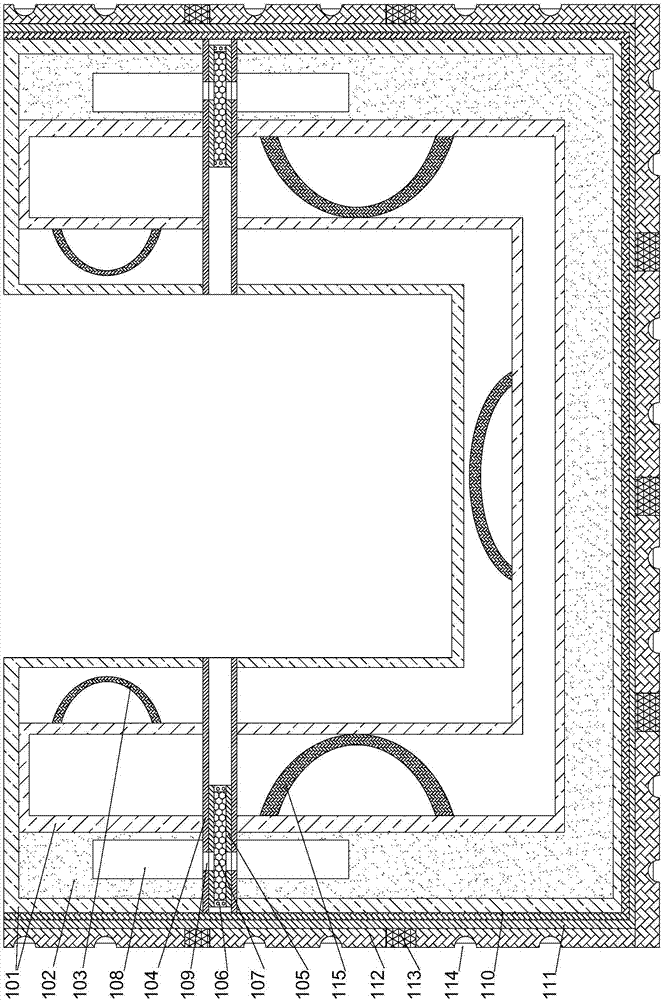

[0024] like figure 1 As shown, a building hollow brick includes a U-shaped hollow steel grid frame 101 in cross section. Reinforcing ribs 103 are arranged between the reinforcement grids 101 described in the layers, and a cavity 108 is provided in the middle of the concrete layer 102, and a water-absorbing resin is filled in the cavity, and the reinforcement grid 101 is provided with a stainless steel pipe 104, the stainless steel pipe 104 runs through the inner and outer two-layer steel grid frame 101 to make the two sides of the steel grid frame 101 on the outer layer communicate with each other, and a PVC support pipe is arranged in the middle of the stainless steel tube 104 105, a foam glass layer 106 is arranged at both ends of the PVC support pipe 105, an irregular through-hole structure is arranged on the foam glass layer 106, and a water-absorbing sponge is arranged in the middle of the PVC support pipe 105 107, the water-absorbing sponge 107 is filled with water-abso...

Embodiment 2

[0031] On the basis of Embodiment 1, this embodiment also discloses a preferred manufacturing method of building hollow bricks, including the following steps:

[0032]S1: Install the steel grid frame 101 structure, weld the support frame 115 on the inner steel grid frame 101, make the support frame 115 arched and weld both ends on the side wall of the steel grid frame 101 on the same side, and the middle part is relatively suspended , welding reinforcing ribs 103 on the outer steel grid frame 101, so that the reinforcing ribs 103 are curved and the two ends are welded on the outer layer steel grid frame 101, the middle part is pressed on the inner layer steel grid frame 101, and the stainless steel pipe 104 erected on the reinforced grid 101;

[0033] S2: Pouring the concrete layer 102, installing a mold between the inner and outer two-layer steel grid frame 101, so that the cavity 108 is formed after pouring the concrete,

[0034] S3: Take out the mold, and fill the cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com