Sandbeach-staying-waiting construction method of cutter suction dredger

A technology of cutter suction dredger and construction method, which is applied in ship construction, ship parts, earth mover/shovel, etc., can solve the problems of frequent assembly and disassembly, low effective utilization rate of ships, long time consumption, etc., and achieves economical efficiency. Significant benefits, increase effective construction time, and improve the effect of construction time utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

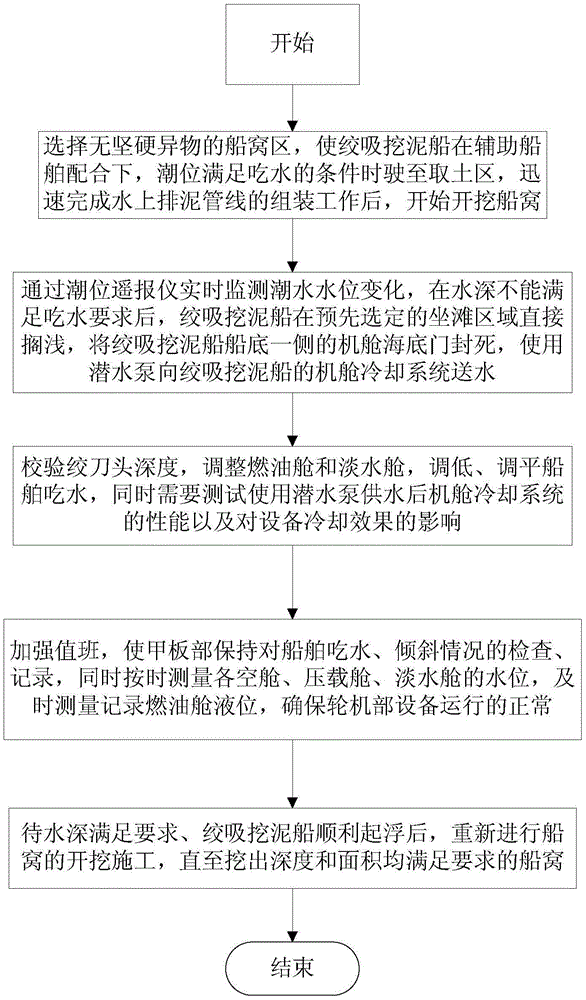

[0015] The construction method of the cutter suction dredger provided by the present embodiment mainly includes the following steps:

[0016] 1. Select a ship nest area without hard foreign objects, and make the cutter suction dredger sail to the soil borrowing area when the tide level meets the draft conditions with the cooperation of auxiliary ships, and start to excavate the ship after quickly completing the assembly of the mud discharge pipeline on the water The nest, the size of the boat nest must be larger than the size of the cutter suction dredger, and the thickness of the excavated mud layer is 6 to 6.5 meters;

[0017] Step 2. Monitor the change of tidal water level in real time through the tide level remote indicator. After the water depth cannot meet the draft requirements, the cutter suction dredger will directly run aground in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com