Preparation method of isobutene-alkyl styrene random copolymer

A technology of alkyl styrene and random copolymer, which is applied in the field of preparation of isobutylene and alkyl styrene random copolymer, can solve the problems such as difficulty in controlling the activity of the initiating system, and achieves reducing molecular weight distribution, increasing reaction temperature, The effect of increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

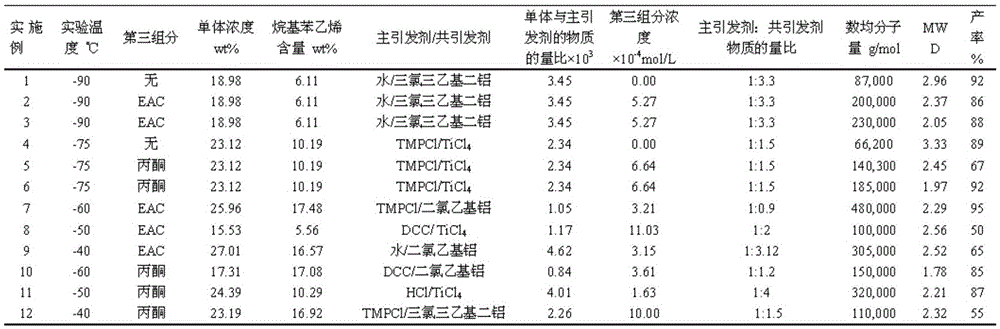

Examples

Embodiment 1

[0037] (1) Reactor feed: at -90°C, add 184g of methyl chloride, 40.5g of isobutylene and 2.6g of p-methylstyrene into the reactor, mix well to form a mixed solution; in the mixed solution, isobutene and p-methylstyrene The total mass concentration of allyl styrene is 18.98wt%;

[0038] (2) Initiator system preparation: take 1.8ml trichlorotriethyl aluminum (0.4M) and 1.8ml CH 2 Cl 2 (0.12M) saturated aqueous solution (the main initiator is water), fully mixed (the amount ratio of the main initiator and the co-initiator is 1:3.3), then add 25ml of methyl chloride solvent to dilute, the main initiator after dilution The concentration is 0.0075mol / L, and then aged at -90°C for 5 minutes to form an initiating system;

[0039] (3) Synthesis of random copolymers: at -90°C, squeeze the initiator system into the reactor to initiate polymerization. After 5 minutes of polymerization, add 20ml of pre-cooled methanol to terminate the reaction, and dry in vacuum to obtain isobutylene and...

Embodiment 2

[0041] (1) Reactor feed: At -90°C, add 184g of methyl chloride, 40.5g of isobutylene and 2.6g of p-tert-butylstyrene to the reactor to form a mixed solution. In the mixed solution, isobutylene and p-tert-butyl The total mass concentration of styrene is 18.98wt%; then add 1.5ml ethyl acetate (0.1M) and mix well;

[0042] (2) Initiator system preparation: take 1.8ml trichlorotriethyl aluminum (0.4M) and 1.8ml CH 2 Cl 2 (0.12M) saturated aqueous solution (the main initiator is water), fully mixed (the ratio of the substance of the main initiator and the co-initiator is 1:3.3), then add 25ml of methyl chloride to dilute, the concentration of the main initiator after dilution is 0.0091mol / L, then aged at -90°C for 5min;

[0043] (3) Synthesis of random copolymer: at -90°C, squeeze the initiator system into the reactor to initiate polymerization. After 5 minutes of polymerization, add 20ml of pre-cooled methanol to terminate the reaction, and dry in vacuum to obtain isobutylene an...

Embodiment 3

[0045](1) Reactor feed: At -90°C, add 184g of methyl chloride, 40.5g of isobutylene and 2.6g of m-methylstyrene into the reactor, mix well to form a mixed solution, and the mixture of isobutene and m-methylstyrene in the mixed solution The total mass concentration of allyl styrene is 18.98wt%;

[0046] (2) Initiator system preparation: take 1.8ml trichlorotriethyl aluminum (0.4M) and 1.8ml CH 2 Cl 2 (0.12M) saturated aqueous solution (the main initiator is water), fully mixed (the amount ratio of the main initiator and the co-initiator is 1:3.3), add 25ml methyl chloride and dilute, the concentration of the main initiator after dilution is 0.0091mol / L, then add 1.5ml ethyl acetate (0.1M), the final concentration of ethyl acetate after mixing is 0.0042mol / L, and age at -90°C for 5min to form an initiating system;

[0047] (3) Polymer synthesis: At -90°C, squeeze the initiator system into the reactor to initiate polymerization. After 5 minutes of polymerization, add 20ml of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com