Method for preparing geopolymer materials from red mud and coal ash

A technology of geopolymer and fly ash, applied in cement production and other directions, can solve the problem that there are not many technologies put into practice, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

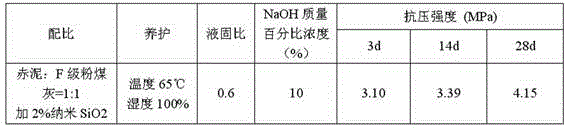

[0018] The ratio of raw materials is shown in Table 1:

[0019] Table 1

[0020]

[0021] Naturally air-dry the required raw materials red mud and fly ash in a ventilated and dry place until the moisture content is not more than 35%, pass through a 0.3mm-0.6mm round-hole sieve after air-drying, bag them separately, and keep them moisture-proof for later use; the concentration of the prepared mass percentage is 10% % sodium hydroxide solution for later use.

[0022] Weigh the red mud and F-class fly ash according to the ratio of 1:1, respectively weigh the red mud and fly ash, and weigh the sodium hydroxide at a liquid-solid ratio, that is, the ratio of the alkali solution to the red mud and fly ash mixture is 0.6 Solution, first mix the red mud and fly ash evenly, then pour into the sodium hydroxide solution and stir for 5-10 minutes, mix evenly in the mortar mixer, pour the evenly stirred red mud and fly ash into the mold release coating In the cement mortar anti-compres...

Embodiment 2

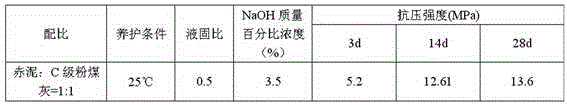

[0024] Raw material ratio scheme is shown in Table 2:

[0025] Table 2

[0026]

[0027] The required raw materials red mud and fly ash are naturally air-dried in a ventilated and dry place until the moisture content is not more than 35%. Prepare a sodium hydroxide solution with a mass percentage concentration of 3.5% for subsequent use. Weigh the red mud and Class C fly ash respectively according to the mass ratio of 1:1, and weigh the sodium hydroxide solution according to the liquid-solid ratio of 0.5.

[0028] First mix red mud and fly ash evenly, then pour into sodium hydroxide solution and stir for 5 to 10 minutes, and mix evenly in a mortar mixer. Pour the uniformly mixed red mud and fly ash into the cement mortar compression test mold coated with a release agent, pound it evenly with a steel tamping rod, place it on a vibrating table to vibrate until the mortar surface comes out, and scrape flat. Place the test mold flat for 24 hours to demould, and place it in ...

Embodiment 3

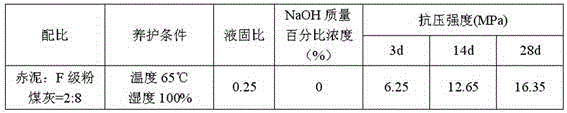

[0030] Raw material ratio scheme is shown in Table 3

[0031] table 3

[0032]

[0033] The required raw materials red mud and fly ash are naturally air-dried in a ventilated and dry place until the water content is not more than 35%. After air-drying, pass through a 0.3mm-0.6mm round-hole sieve, and bag them separately to prevent moisture for later use. Weigh the red mud and F-class fly ash according to the mass ratio of 2:8, and weigh the clear water with a liquid-solid ratio of 0.25.

[0034] First, mix the red mud and fly ash evenly for 5-10 minutes, and mix them evenly in a mortar mixer. Pour the uniformly mixed red mud and fly ash into the cement mortar anti-compression test mold coated with a release agent, pound it evenly with a steel tamping rod, place it on a vibrating table and vibrate until the surface of the mortar comes out, and Scrape. Place the trial mold flat for 24 hours to demould, and place it in a curing room (65°C, 100% humidity) for curing. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com