Method for preparing silicon oxide nanofiber

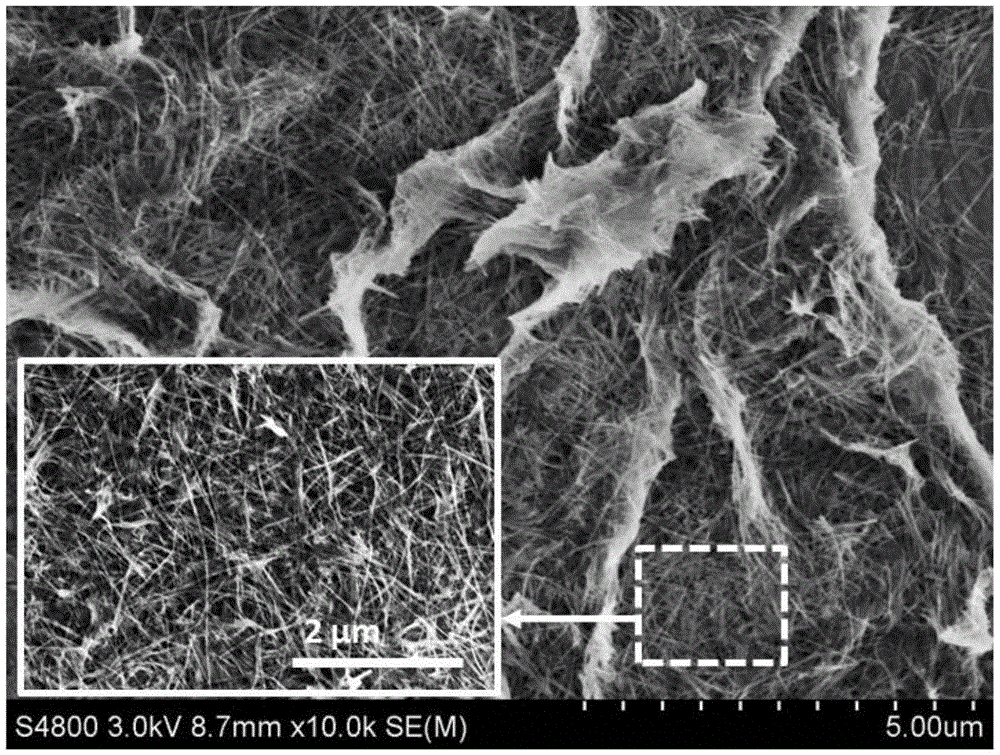

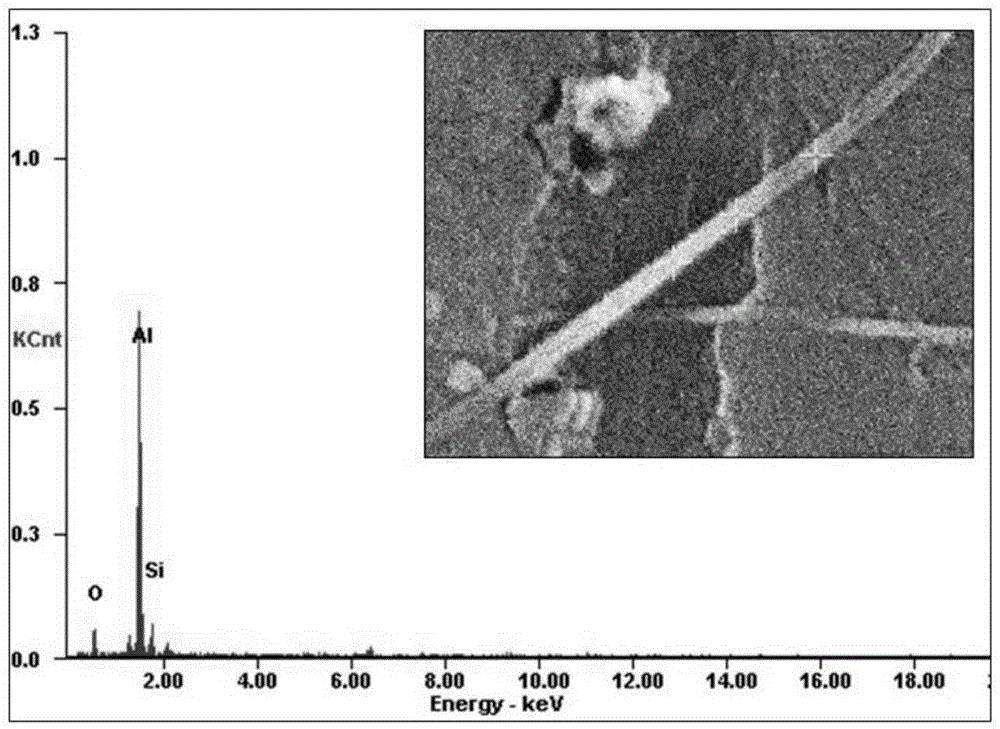

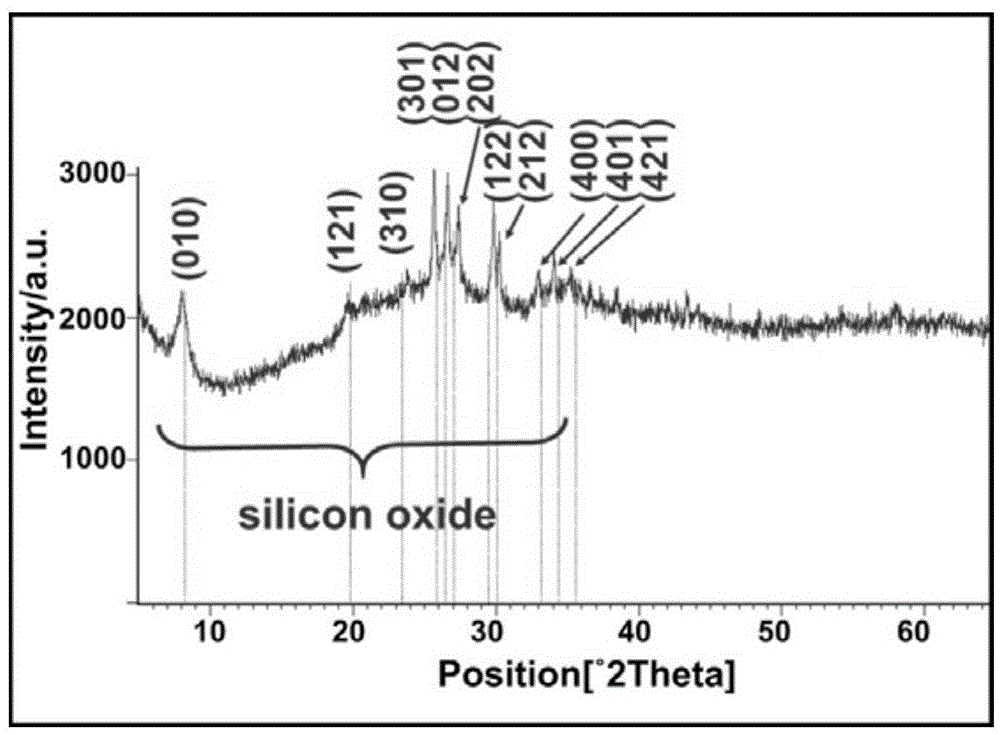

A nanofiber and silicon oxide technology, applied in the field of nanomaterials, can solve the problems of many nanowire products, poor flexibility, high synthesis temperature, etc., and achieve good product reproducibility, convenient and efficient preparation method, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 3.75 g of SiO with a mass fraction of 30% 2 Silica sol (basic), add 37.5 ml of distilled water. After stirring and ultrasonically dispersing evenly, weigh 15.14 grams of Fe(NO 3 ) 3 .9H 2 O (ferric nitrate nonahydrate) was added to the aqueous silica sol solution and stirred for 15 minutes until the ferric nitrate was completely dissolved.

[0032] Subsequently, the above solution was slowly added dropwise into a flask filled with 60 ml of ethylenediamine liquid, and magnetic stirring (500 rpm) was performed during the dropwise addition. After the dropwise addition of the solution was completed, the emulsion was stirred for 15 hours to fully mix the system uniformly to obtain a mixed solution.

[0033] The above mixed solution was transferred into a 150 ml polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and left to stand in an oven at 180 degrees Celsius for 4 days to carry out hydrothermal reaction.

[0034] After the reaction was compl...

Embodiment 2

[0041] Weigh 3.75 g of 30% basic SiO 2 Silica sol, add 37.5 ml of distilled water. After stirring and ultrasonically dispersing evenly, weigh 6.36 g of AgNO 3 (Silver nitrate) was added to the aqueous solution of silica sol, and stirred for 20 minutes until the silver nitrate was completely dissolved.

[0042] Subsequently, the above solution was slowly added dropwise into a flask filled with 60 ml of ethylenediamine liquid, and magnetic stirring (500 rpm) was performed during the dropwise addition. After the dropwise addition of the solution was completed, the emulsion was stirred for 12 hours to fully mix the system uniformly to obtain a mixed solution.

[0043] The above mixed solution was transferred into a 150 ml polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and left to stand in an oven at 170 degrees Celsius for 4 days.

[0044] After the reaction was complete, the reactor was taken out and cooled to room temperature. The precipitates in the r...

Embodiment 3

[0048] Weigh 15 g of 30% Alkaline SiO 2 Silica sol, add 150 ml of distilled water. After stirring and ultrasonically dispersing evenly, weigh 30 grams of Fe(NO 3 ) 3 .9H 2 O (ferric nitrate nonahydrate) was added to the aqueous silica sol solution and stirred for 30 minutes until the silver nitrate was completely dissolved.

[0049] Subsequently, the above solution was slowly added dropwise into a flask filled with 240 ml of ethylenediamine liquid, and magnetic stirring (500 rpm) was carried out during the dropwise addition. After the dropwise addition of the solution was completed, the emulsion was stirred for 15 hours to fully mix the system uniformly to obtain a mixed solution.

[0050] The above mixed solution was moved into a 1L 1Cr18Ni9Ti high temperature and high pressure stainless steel reaction kettle, the pressure inside the kettle was maintained at 2MPa, and the reaction was carried out at a temperature of 170 degrees Celsius for 3 days.

[0051] After the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com