Main and auxiliary span circular yard

A circular stock yard and arc-shaped technology, applied in the field of main and auxiliary span circular stock yards, can solve the problems of reduced equipment reliability, reduced material shed safety, increased difficulty in material shed design and civil construction investment, etc. The effect of civil construction investment and increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

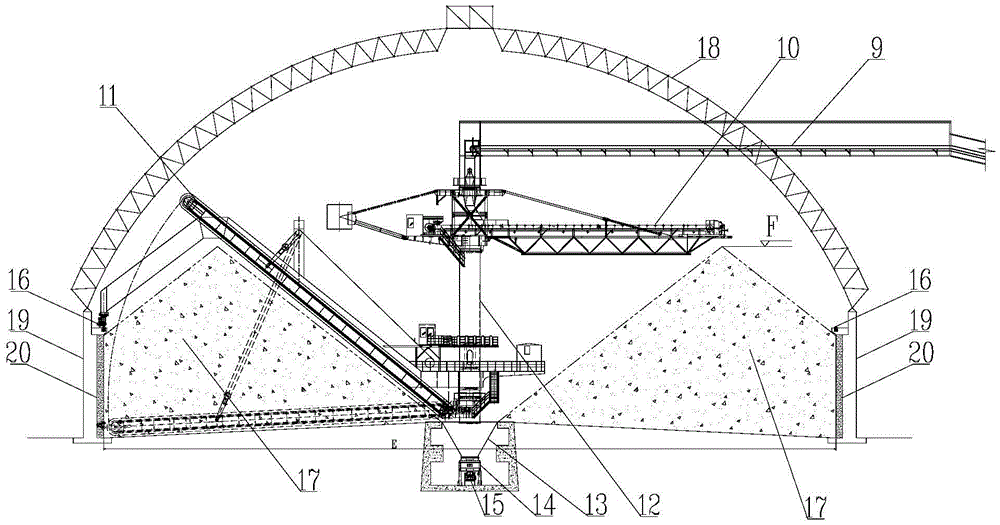

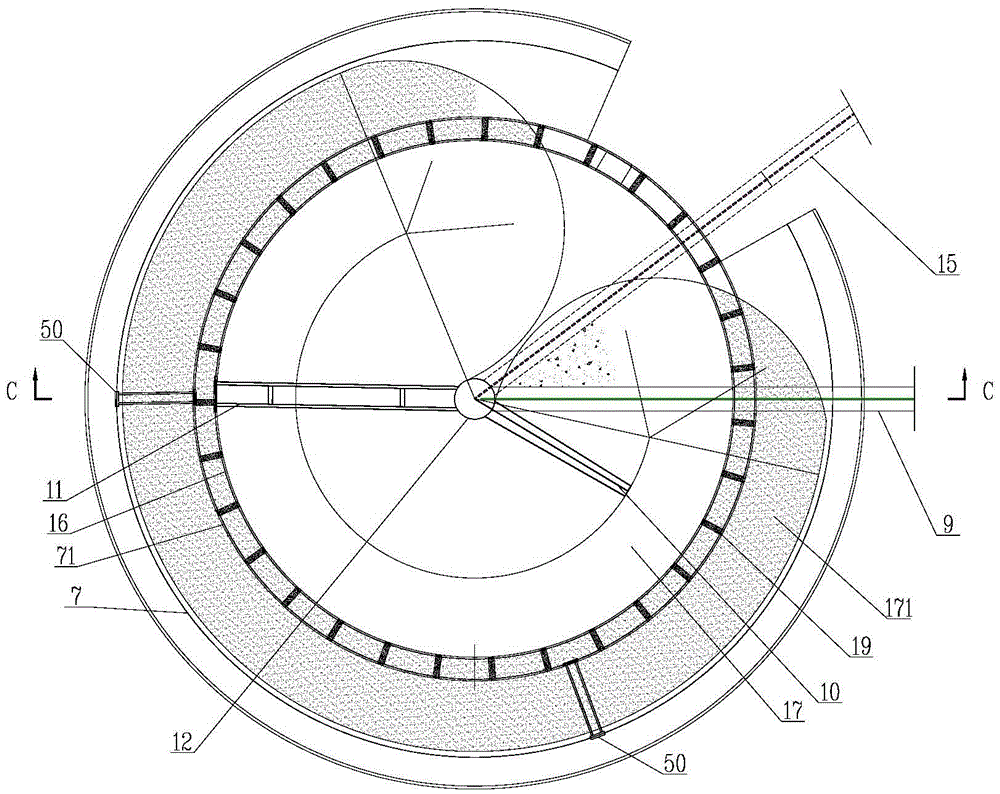

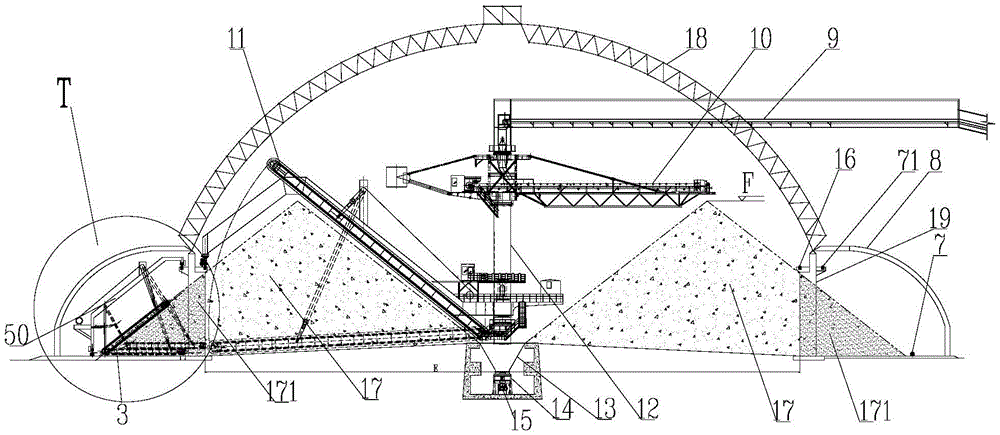

[0029] Such as Figure 2-6 As shown, the main and auxiliary span circular stockyards in this embodiment include a number of pillars 19 arranged at intervals in a ring structure, and the arc-shaped main span shed 18 is supported on the pillars 19, and the distance between the outer surface of the pillars 19 and the ground is The annular structure formed along the pillars is provided with an arc-shaped auxiliary span shed 8, the upper end of the arc-shaped auxiliary span shed 8 is sealed and connected with the lower end of the arc-shaped main span shed 18, and the arc-shaped main span shed 18 is connected with the arc-shaped main span shed 8. Shaped auxiliary span shed 8 forms the enclosed material storage space of stockyard. A center column 12 is arranged below the central position corresponding to the arc-shaped main span shed 18, and a center funnel 13 is arranged on the lower part of the ground corresponding to the center column 12, and a center funnel 13 is arranged below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com