Tank-type container tank box tank body and frame connecting structure

A technology of tank container and connection structure, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of poor overall stress condition and self-heavy tank container, achieve compact and lightweight tank structure, improve the overall load Strength status, the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

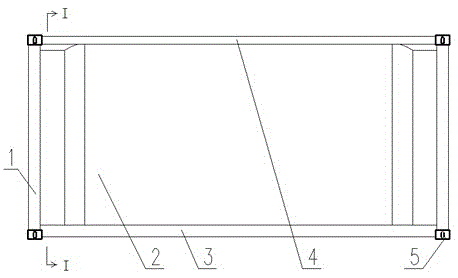

[0030] This device comprises tank body 2, connecting cylinder 10 and container frame, such as figure 1 , figure 2 shown;

[0031] The tank body 2 is provided with a liquid phase port, a gas phase port, a safety valve port, etc.;

[0032] Connect the cylinder 10, one end is welded to the tank body 2, and the other end is welded to the end frame 1 of the frame;

[0033] The container frame is an open frame structure, and the tank body and connecting cylinder are installed in the frame.

[0034] The "bridge" type tank container in which the tank body 2 and the frame are organically combined through the connecting cylinder 10, such as image 3 , Figure 4 shown.

[0035] The connecting cylinder 10 can be directly welded to the head of the tank body 2, such as image 3 As shown, a transition support ring 11 can also be set in the middle, such as Figure 4 As shown, in order to solve the problem that the tank body that requires heat treatment or vacuuming can no longer be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com