A method for producing macroscopic tensile plasticity in ductile metallic glass

A tough metal, tensile plastic technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of annealing brittleness restricting applications and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

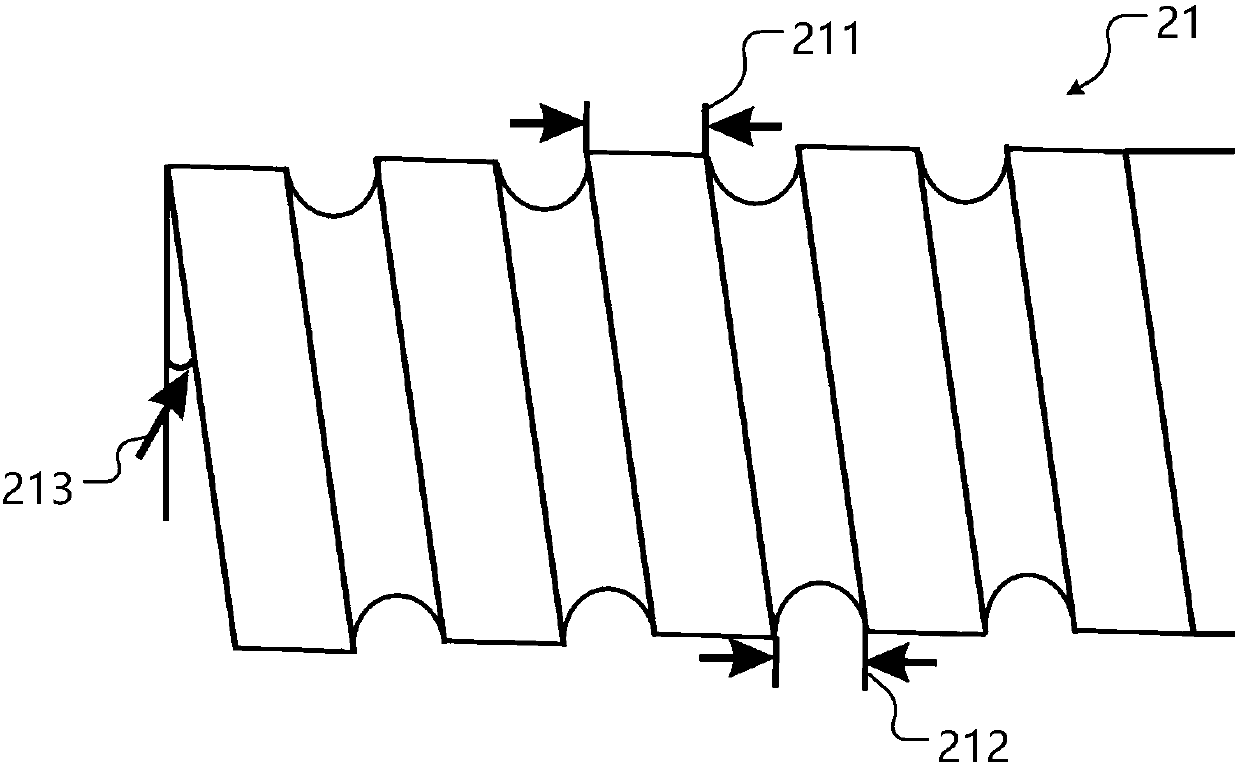

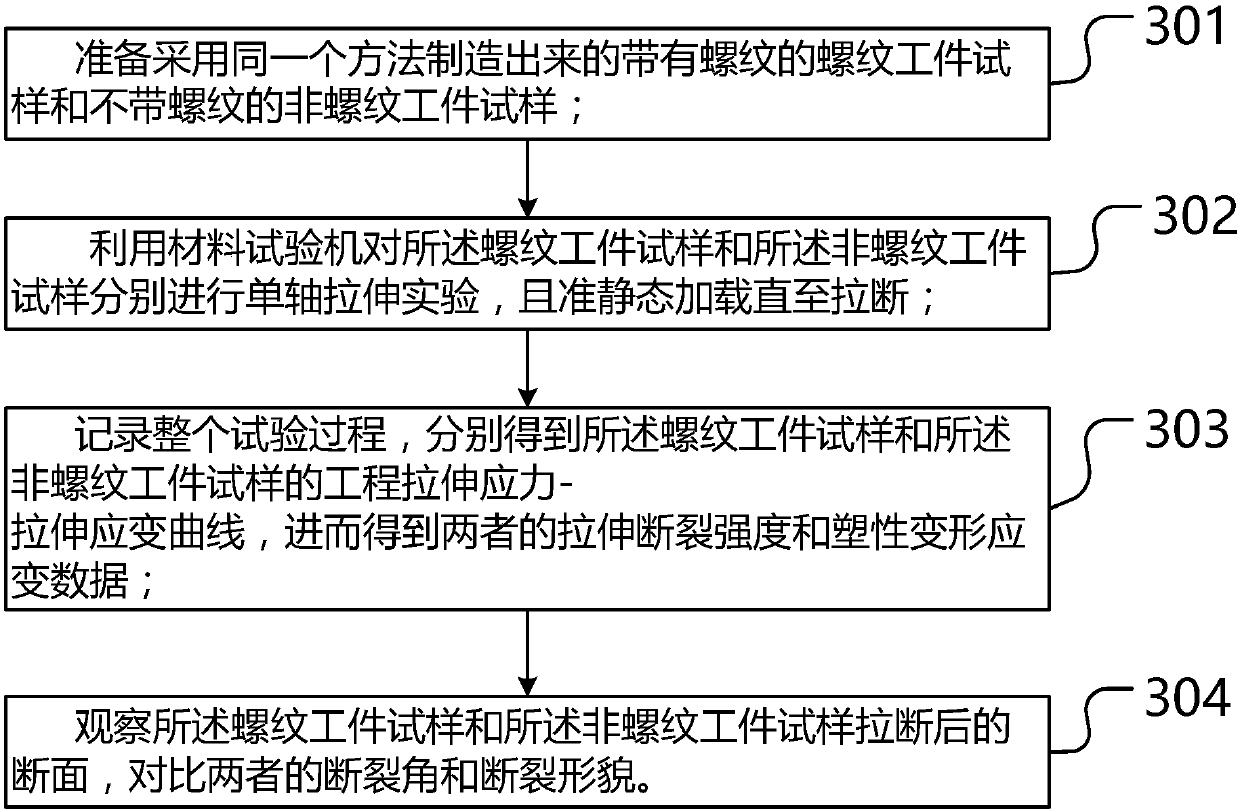

[0036] Such as figure 1 Shown is a schematic flow diagram of a method for producing macroscopic tensile plasticity in ductile metallic glass according to an embodiment of the present invention. The method includes the following steps:

[0037] Step 100, prepare the ductile metallic glass to be processed, and make it into a rod-shaped workpiece, and determine the length and diameter data of the workpiece;

[0038] The ductile metallic glass here is a kind of metallic glass system that can undergo ductile fracture and has relatively good plastic deformation ability, including most metals such as zirconium-based, titanium-based, copper-based, iron-based, nickel-based, palladium-based, platinum-based, etc. glass system.

[0039] After the rod-shaped structure is made, it is easy to uniformly set the effective stress area on the workpiece. The length and diameter of the workpiece can be adjusted according to actual needs. The workpiece used in this embodiment is a zirconium-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com