Hydraulic docking device used outside large-caliber gathering and transportation pipeline

A large-caliber, hydraulic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as equipment construction and docking difficulties, reduce labor intensity, ensure docking accuracy, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

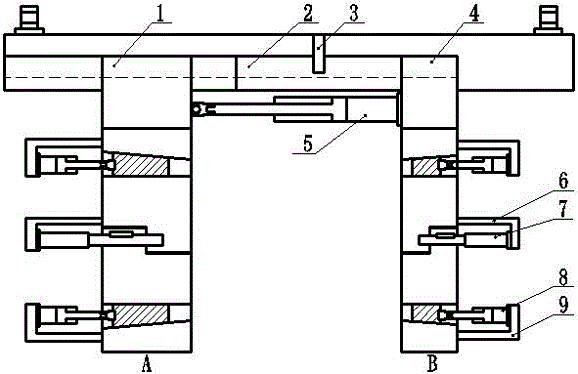

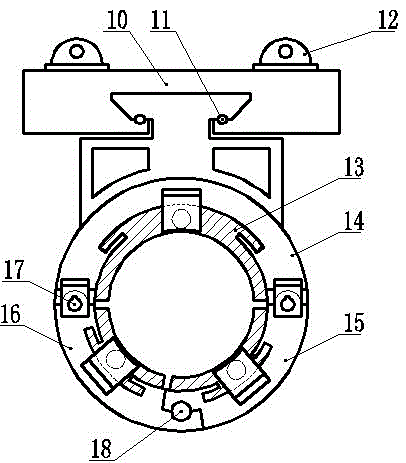

[0012] like figure 1 , figure 2 and image 3 As shown, a hydraulic large-diameter gathering and transportation pipeline external docking device of the present invention is composed of a mobile sliding table 1, a positioning sliding table 2, a positioning pin 3, a fixed sliding table 4, a horizontally moving double-acting hydraulic cylinder 5, and a swing hydraulic motor Base 6, swing hydraulic motor 7, horizontal push hydraulic cylinder 8, horizontal push hydraulic cylinder base 9, workbench 10, sliding ball 11, lifting lug 12, wedge-shaped locking ring 13, fixed holding ring 14, right rotating holding ring 15 1, left rotating ring 16, rotating pin shaft 17 and locking pin 18; its structural features are: the mobile sliding table 1 and the fixed sliding table 4 are loaded into the dovetail groove slideway from the open end of the workbench 10, and the arc end passes through Welding and fixing the ring 14; the positioning sliding table 2 is loaded into the dovetail groove sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com