Automatic tailor-welding tool for reel sprinkler reel wing plate

A technology of machine coils and wing plates, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems affecting production progress, low equipment utilization, high skills and proficiency requirements, etc., to reduce the impact on production progress, The effect of reducing labor intensity and ensuring the quality of tailor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

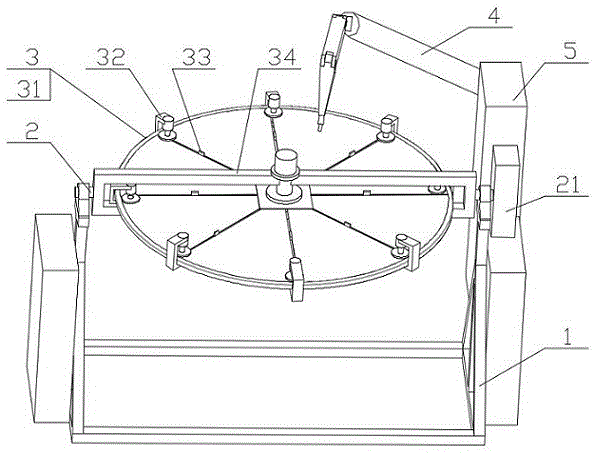

[0038] Because the hydraulic control has a higher stable output force, it is conducive to the overall overturning of the heavier workpiece support part 3, the rotation of the heavier movable support plate 34 of the bearing wing plate workpiece, and the overload of the motor can be prevented, so as another aspect of the present invention In this embodiment, the reel flap automatic tailor welding tooling of the reel sprinkler irrigation machine also includes a hydraulic pump station, the hydraulic pump station includes a control valve group, and the turning drive device 21 and the rotary drive mechanism of the workpiece support part 3 both include a hydraulic pump station. The motor and the control valve group of the hydraulic pump station are respectively connected to the hydraulic motor through hydraulic pipelines, the output shaft of the hydraulic motor of the turning drive device 21 is connected to the turning shaft 2 through a connecting mechanism, and the hydraulic motor of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com