Rolling welding machine for steel bar frame, method for making steel bar frame and method for making square pile

A steel skeleton and roll welding machine technology, applied in the direction of roller electrode welding, manufacturing tools, welding equipment, etc., can solve the problems that the steel skeleton is not easy to make, the production process is time-consuming and laborious, and there are not many studies, so as to improve the production efficiency and ensure The effect of manufacturing precision and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

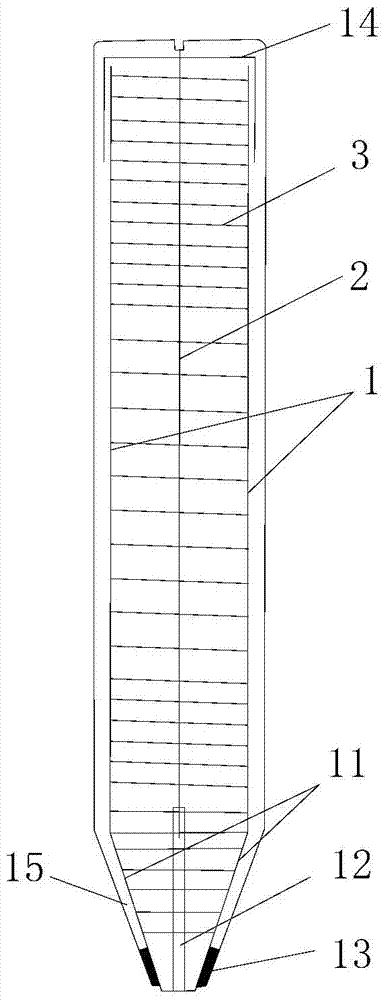

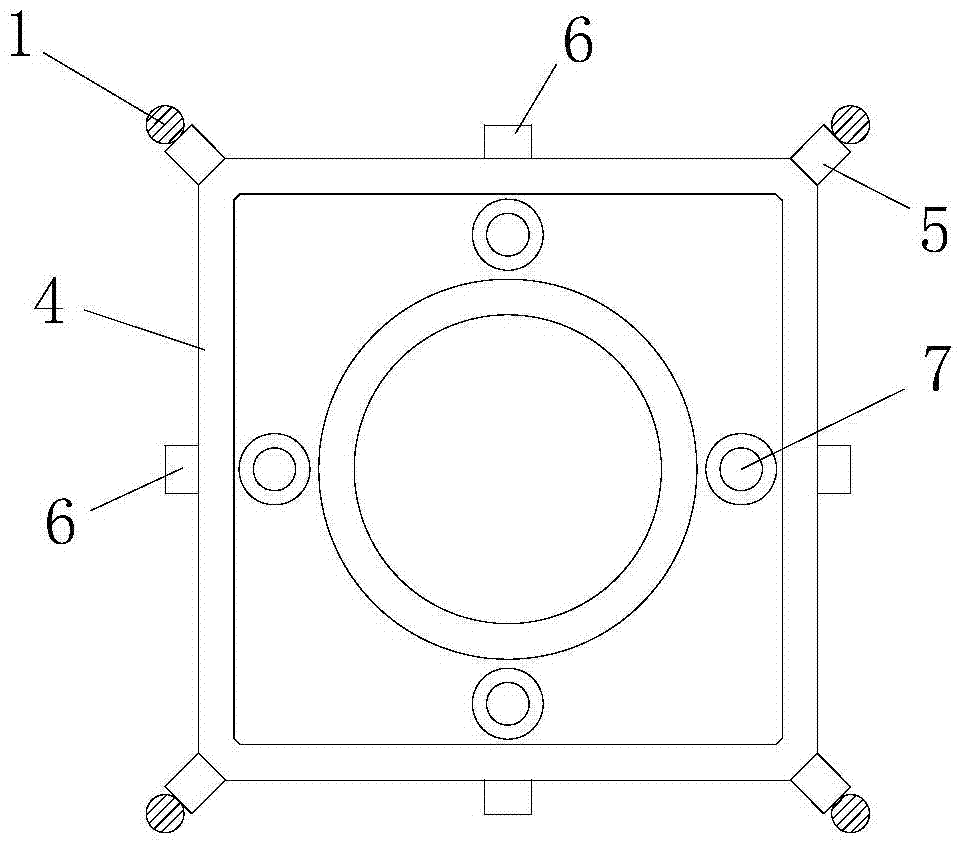

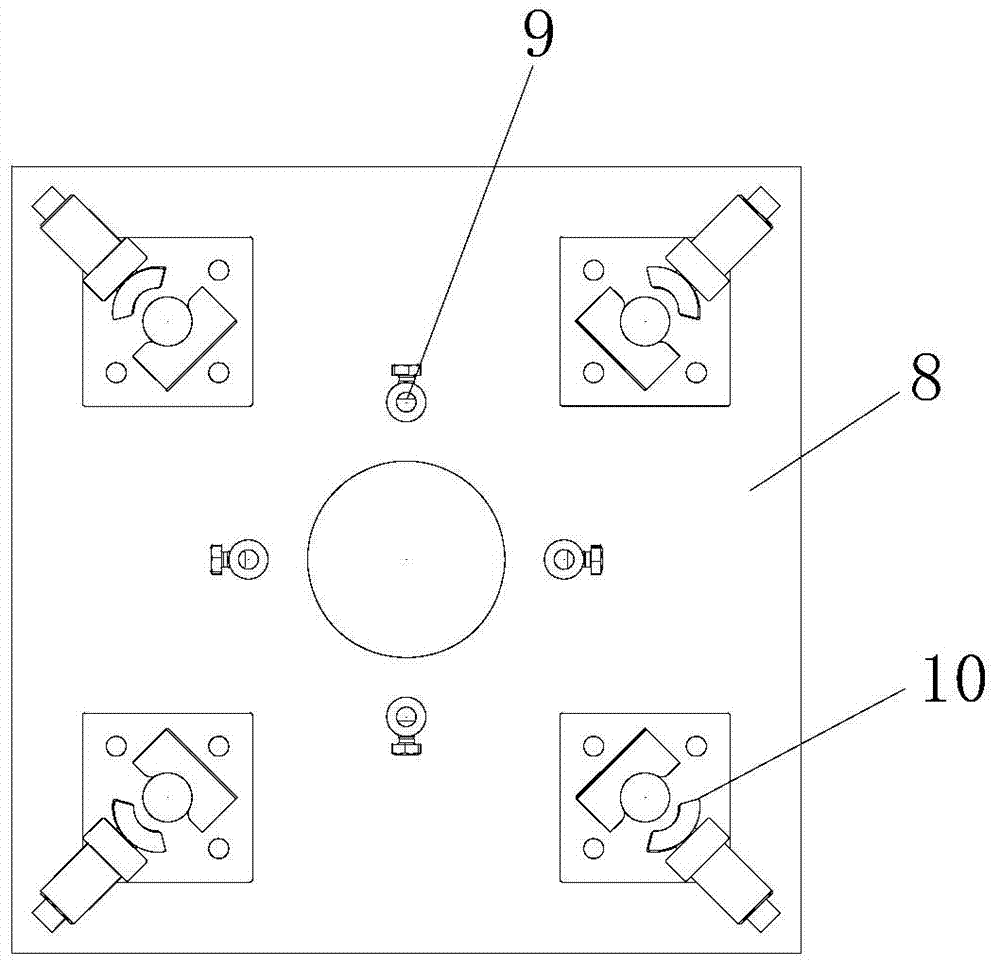

[0045] Such as Figure 1 to Figure 3 As shown, the present invention also discloses a steel frame seam welding machine, the cross section of the steel frame is square, the steel frame includes non-prestressed main bars, prestressed main bars and stirrups 3, and the stirrups 3 are cold-drawn low-carbon steel wires Or low-carbon steel hot-rolled round wire rod, the non-prestressed main reinforcement includes four non-prestressed main reinforcements 1 respectively arranged at the corners of the square steel skeleton, and the four non-prestressed main reinforcements 1 are HRB400 steel bars; the prestressed main reinforcement adopts Four steel strands 2, four steel strands 2 are respectively evenly distributed in the middle of the four sides of the square reinforcement skeleton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com