Nozzle head, metal particle manufacturing device using same, and manufacturing method thereof

A nozzle head and nozzle technology, applied in the field of nozzle heads, can solve problems such as sphericity reduction and achieve the effect of highly uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0024] (structure)

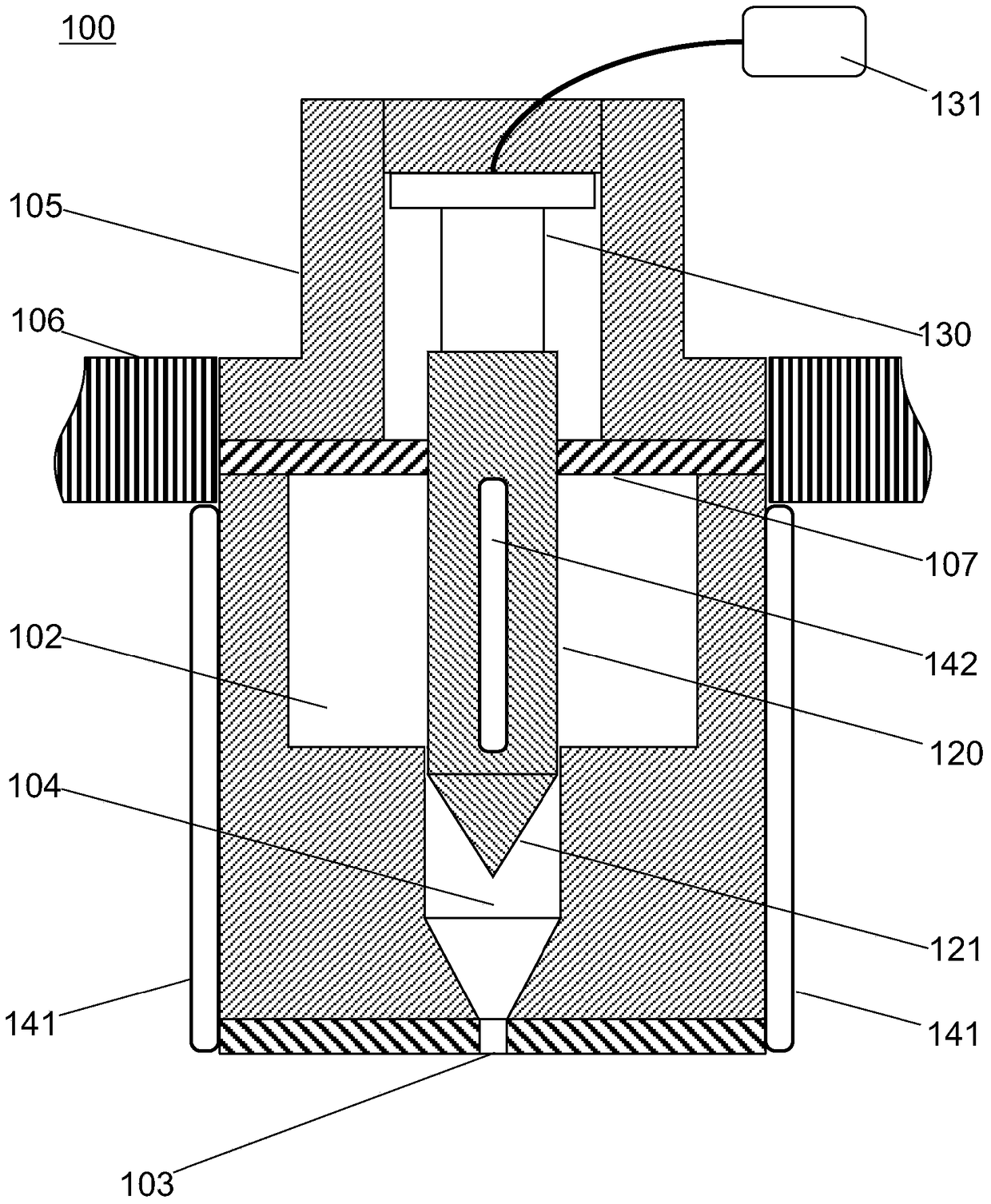

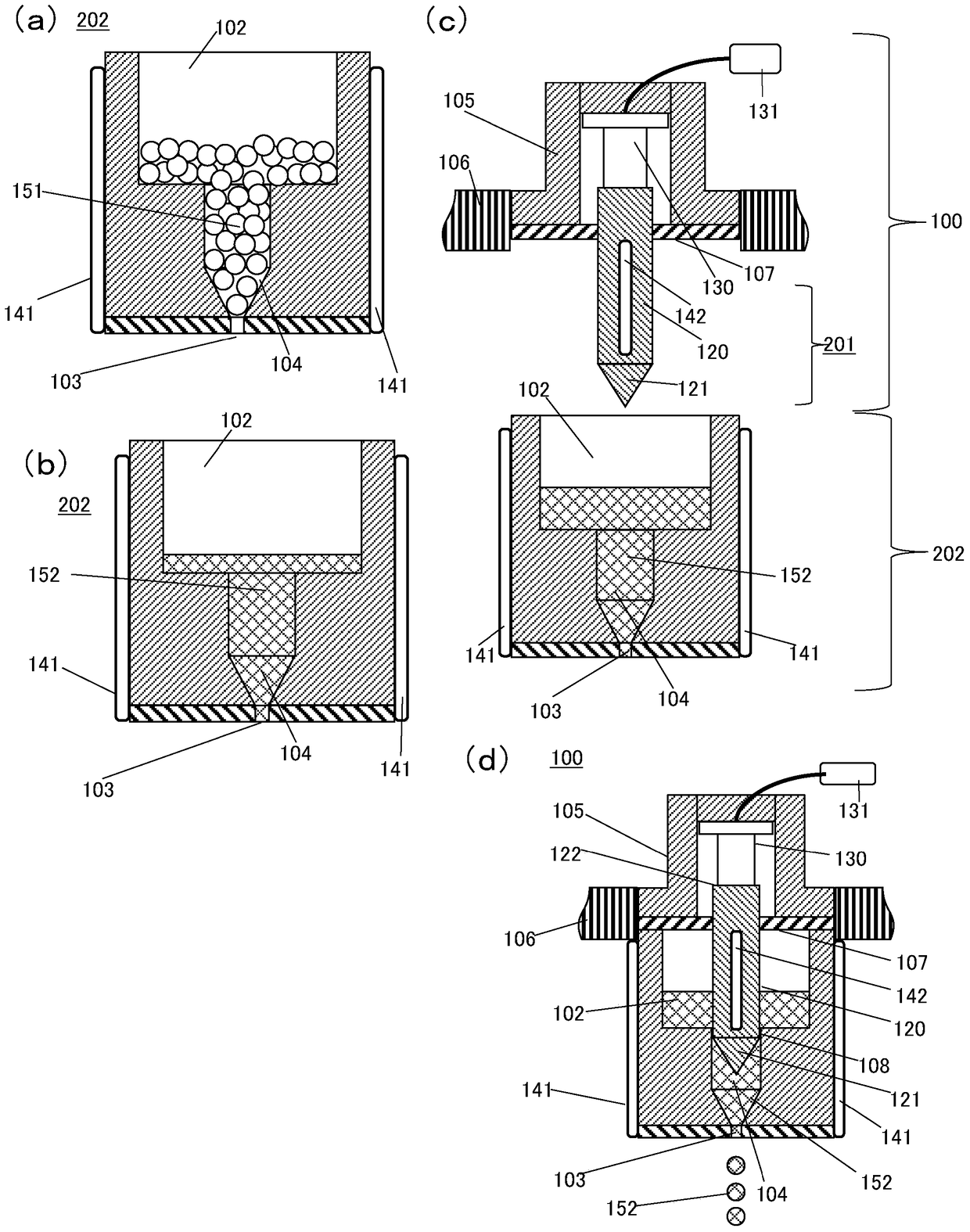

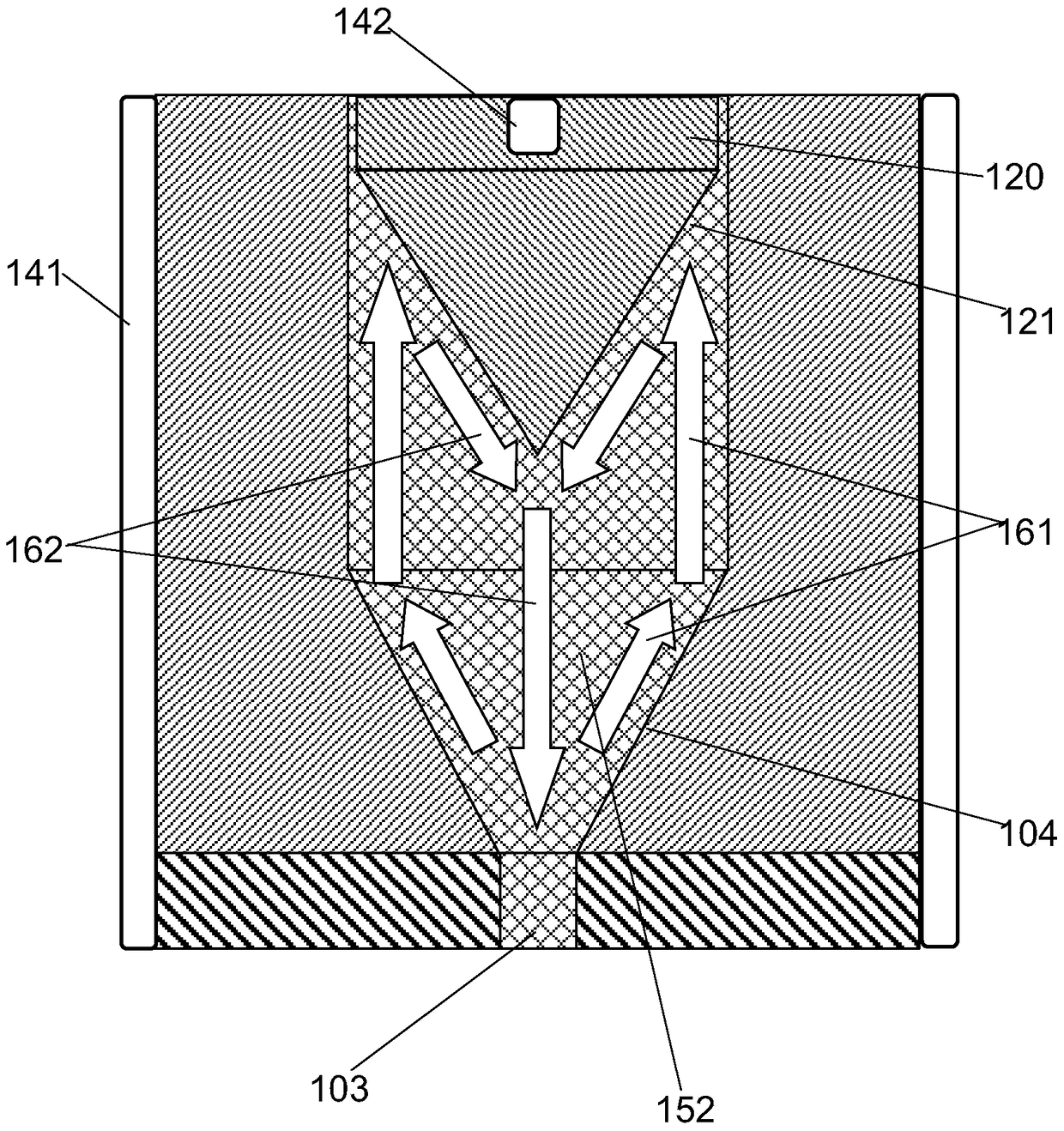

[0025] figure 1 It is a schematic diagram showing the cross-sectional structure of the nozzle head in the embodiment viewed from the front. A supply chamber 102 storing a metal material as a raw material is provided on the nozzle head 100 . A heating mechanism 141 is provided around the supply chamber 102, and heats and melts the metal material above its melting point. In addition, the nozzle head 100 includes a nozzle 103 that ejects molten metal. Furthermore, it is provided with the pressure chamber 104 which communicates with the nozzle 103 and generates the pressure for ejecting molten metal material. The supply chamber 102 and the pressure chamber 104 are separated by a piston 120 . Therefore, the pressure chamber 104 and the supply chamber 102 are simultaneously heated from the outside by the heating mechanism 141 . Furthermore, the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com