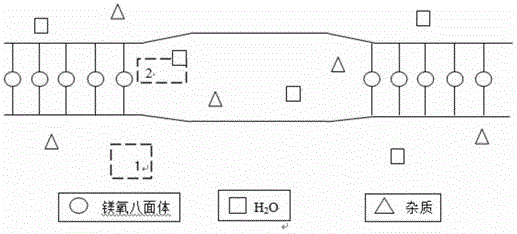

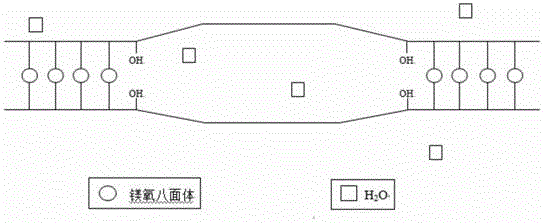

Method of using low-quality short fiber sepiolite for preparing high-performance adsorbing material

An adsorption material, sepiolite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low treatment process efficiency, insufficient development and utilization of sepiolite adsorption performance, etc., to achieve significant adsorption performance and excellent adsorption performance , the effect of reducing the amount of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

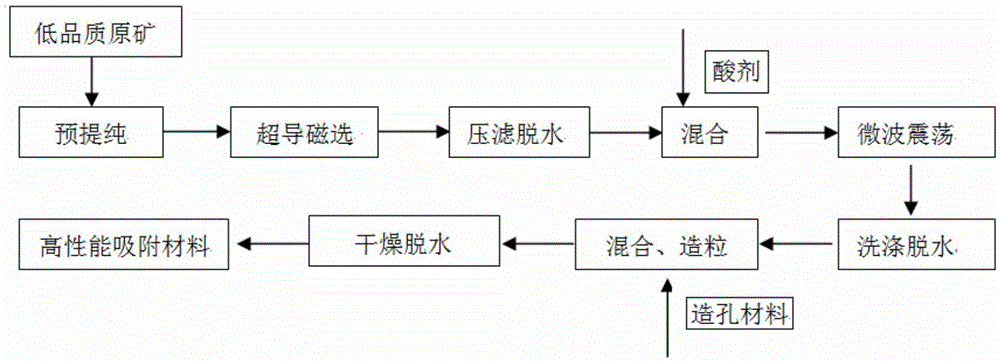

[0035]Example 1: A method for preparing high-performance adsorption material with low-quality short-fiber sepiolite

[0036] The method comprises the following steps, and the process flow chart is referring to the appended figure 1 Shown:

[0037] (1) Pre-purification of low-quality short-fiber sepiolite raw ore: prepare low-quality short-fiber sepiolite raw ore into pulp with a mass concentration of 8-15%, and then pass the pulp through a vibrating screen with a sieve hole of 0.1mm, After a φ75 cyclone and a horizontal centrifuge, the sepiolite concentrate with a mass purity of 80% is purified, and the mass concentration of the pulp becomes 2.6% at this time; wherein, the sepiolite in the low-quality short-fiber sepiolite raw ore The mass percentage of sepiolite is less than 40%, and the fiber length of sepiolite is less than 1.5 μm;

[0038] (2) After the step (1) is completed, the ore pulp is processed by a superconducting magnetic separator with a high magnetic field str...

Embodiment 2

[0044] Example 2: A method for preparing high-performance adsorption material with low-quality short-fiber sepiolite

[0045] The method comprises the steps of:

[0046] (1) Pre-purification of low-quality short-fiber sepiolite raw ore: prepare low-quality short-fiber sepiolite raw ore into pulp with a mass concentration of 8-15%, and then pass the pulp through a vibrating screen with a sieve hole of 0.1mm, After a φ75 cyclone and a horizontal centrifuge, the sepiolite concentrate is purified to a mass purity of 85%, and the mass concentration of the pulp becomes 5% at this time; wherein, the sea foam in the low-quality short-fiber sepiolite ore The mass percentage of sepiolite is less than 40%, and the fiber length of sepiolite is less than 1.5 μm;

[0047] (2) After the step (1) is completed, the ore pulp is processed by a superconducting magnetic separator with a high magnetic field strength, the magnetic field strength is 4T, the magnetic substances in the ore pulp are re...

Embodiment 3

[0053] Example 3: A method for preparing high-performance adsorption material with low-quality short-fiber sepiolite

[0054] The method comprises the steps of:

[0055] (1) Pre-purification of low-quality short-fiber sepiolite raw ore: prepare low-quality short-fiber sepiolite raw ore into pulp with a mass concentration of 8-15%, and then pass the pulp through a vibrating screen with a sieve hole of 0.1mm, After a φ75 cyclone and a horizontal centrifuge, the sepiolite concentrate is purified to a mass purity of 85%, and the mass concentration of the pulp becomes 2% at this time; wherein, the sepiolite in the low-quality short fiber sepiolite raw The mass percentage of sepiolite is less than 40%, and the fiber length of sepiolite is less than 1.5 μm;

[0056] (2) After the step (1) is completed, the ore pulp is processed by a superconducting magnetic separator with a high magnetic field strength, the magnetic field strength is 3T, the magnetic substances in the ore pulp are r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com