Colored composition, cured film, color filter, method for manufacturing color filter, solid-state imaging element, image display device, and compound

A coloring composition, color filter technology, applied in the direction of optical filters, optical elements, chemical instruments and methods, etc., can solve the problems of scattering, poor dispersion stability, viscosity increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0741] [Preparation method of coloring composition]

[0742] The coloring composition of the present invention is prepared by mixing the above-mentioned respective components and optional optional components.

[0743] In addition, when preparing a coloring composition, each component which comprises a coloring composition may be mix|blended at once, and each component may be melt|dissolved and dispersed in a solvent, and it may mix|blend sequentially. In addition, there are no particular restrictions on the order of loading or working conditions when blending is performed. For example, the composition can be prepared by dissolving and dispersing all the components in a solvent at the same time. If necessary, each component can be prepared into two or more kinds of solutions and dispersions as appropriate, and these solutions can be mixed at the time of use (coating) - Dispersion liquids are mixed to prepare a composition.

[0744] The coloring composition prepared in this ma...

Embodiment

[0818] Hereinafter, an Example is given and this invention is demonstrated more concretely. Unless departing from the gist of this invention, the material, usage-amount, ratio, process content, process procedure etc. which are shown in the following Example can be changed suitably. Therefore, the scope of the present invention is not limited to the specific examples shown below. In addition, unless otherwise specified, "%" and "part" are mass standards.

[0819]

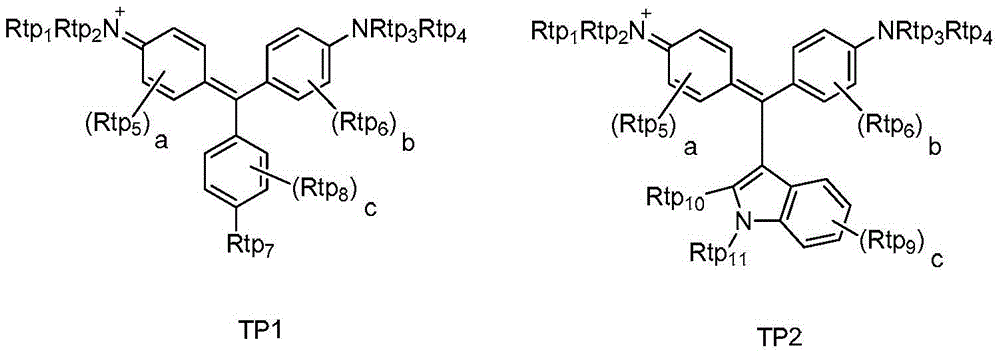

[0820] (Synthesis of compound 1-9 (triarylmethane dye (I-9)))

[0821] Compounds 1-9 were synthesized according to the following routes.

[0822] [chem 92]

[0823]

[0824] (Synthesis of Synthetic Intermediate (Compound 3))

[0825] After dissolving 17.0 g (118.8 mmol) of compound 1 (1-naphthylamine) and 11.65 g (118.7 mmol) of 1,2-epoxycyclohexane in 50 mL of hexafluoroisopropanol, it heated and refluxed for 5 hours. After confirming the completion of the reaction, the target substance was extracted into ...

Embodiment 2~ Embodiment 27

[0851] A coloring composition was prepared in the same manner as in Example 1, except that the triarylmethane dye (I-1) was changed to the following (I-2) to (I-21) and (I-101) to (I-106). .

[0852] [chem 95]

[0853]

[0854] [chem 96]

[0855]

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com