Formic acid decomposition apparatus and formic acid decomposition method

A technology of formic acid and decomposition, applied in separation methods, auxiliary devices, chemical instruments and methods, etc., can solve problems such as corrosion, scattering and adhesion, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to a following Example.

[0099] (experiment method)

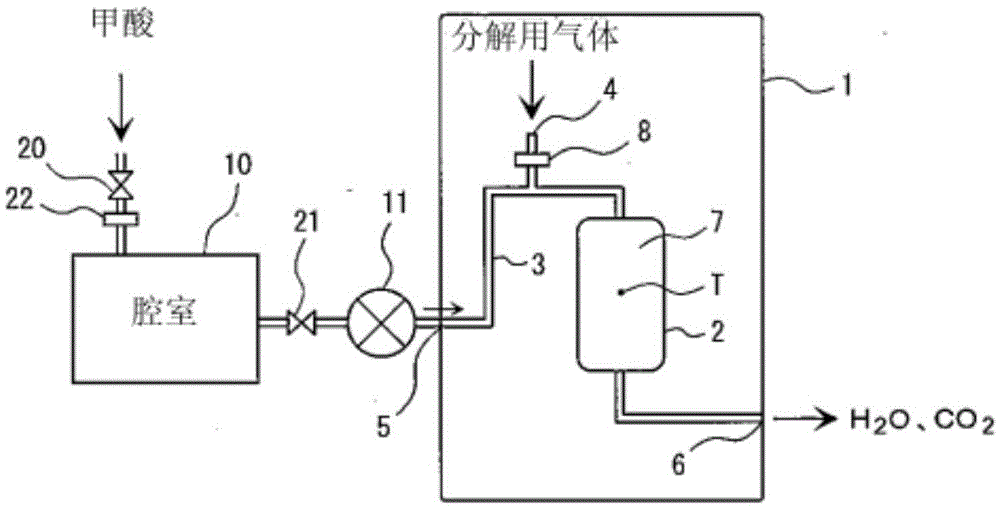

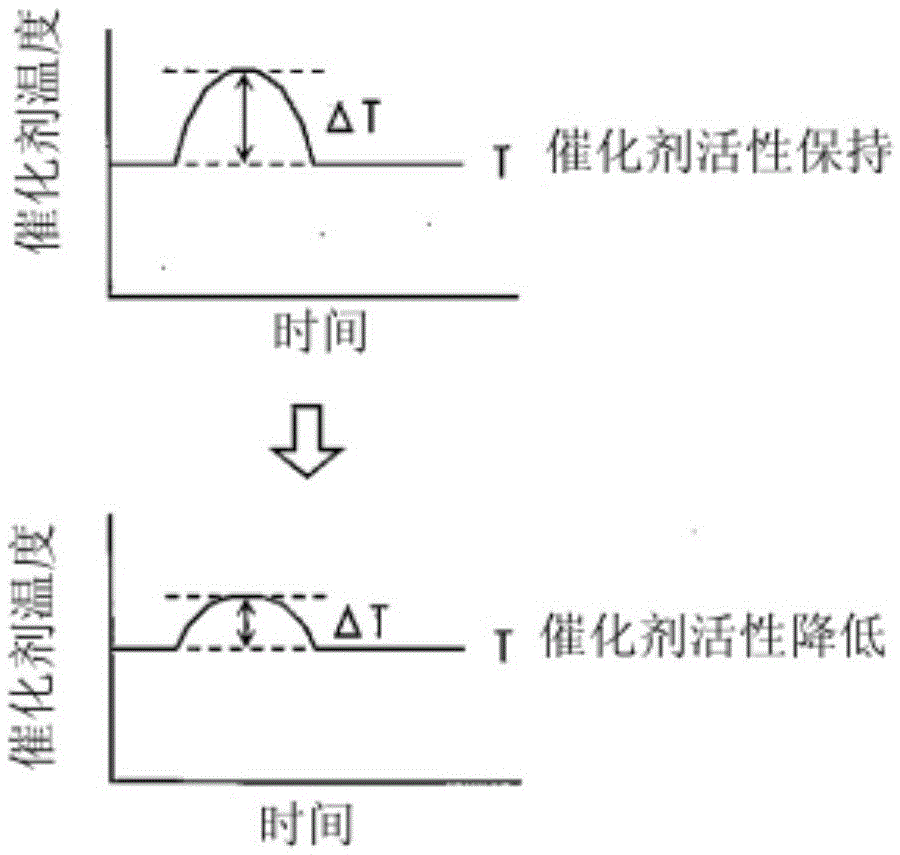

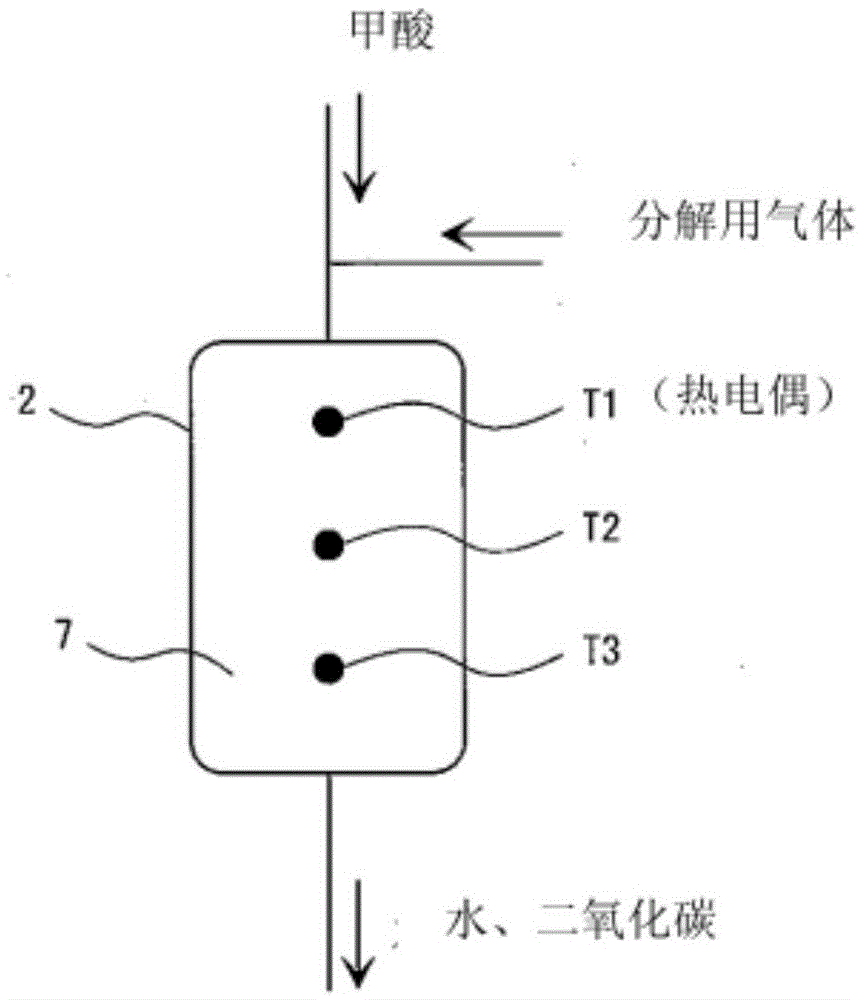

[0100] figure 1 In the shown apparatus, the capacity of the chamber 10 is 20 L, and the test was performed using the apparatus which filled the formic-acid decomposition part 2 with 1 L of catalyst. In addition, if image 3 As shown, in the formic acid decomposition part 2, thermocouples T1, T2, and T3 are provided at three positions of the upstream part, the middle part, and the downstream part of the catalyst layer. These thermocouples are installed at the center of the catalyst layer. As a catalyst, a Pt / alumina catalyst in which 1.8 g / L of Pt (platinum) was attached to granular alumina was used. In order to judge the activity of the catalyst, a part of the catalyst whose activity has been lowered was also used together for a test.

[0101] The test method is as follows. In the state where valve 20 an...

Embodiment 1

[0107] As a catalyst, a Pt / alumina catalyst in which 1.8 g / L of platinum was attached to granular alumina was used. 1 L of the newly prepared catalyst was filled in the formic acid decomposition unit 2 to prepare a catalyst layer, and a test was performed according to the above-mentioned test method (referred to as test (a)).

[0108] Next, prepare 330 ml of catalysts with reduced catalyst activity, fill them into the upper 1 / 3 of the formic acid decomposition unit 2 (the lower 2 / 3 is filled with the freshly prepared catalyst used in the test (a), and perform the test according to the aforementioned test method (As test (b)).

[0109] In addition, prepare the catalyst 330ml that catalyst activity loses completely, fill in the part of the top 1 / 3 of formic acid decomposition part 2 (bottom 2 / 3 is filled with the catalyst that is used for test (a) newly prepared), test according to the aforementioned test method ( Let it be test (c)).

[0110] In tests (a), (b), and (c), chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com