Novel wind power cable

A wind energy and cable technology, applied in the field of wire and cable, can solve problems affecting the reliability of wind power generation, environmental pollution, etc., and achieve the effects of natural hanging, improved tensile and compressive resistance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

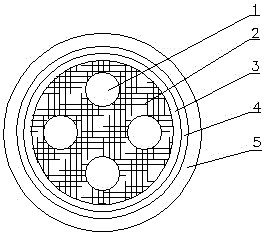

[0010] exist figure 1 Among them, the cable core of the new wind energy cable is composed of several wire cores 1 wrapped with ethylene propylene rubber 2, the wire core 1 is composed of a conductor wrapped with ethylene propylene rubber insulation layer, and the cable core is equipped with a stainless steel wire shielding layer 3, and the stainless steel wire shield An aramid fiber layer 4 is arranged on the outside of the layer 3, and the outer layer of the aramid fiber layer 4 is a sheath layer composed of a PUR elastomer compound 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com